Lead welding device and technique for packaging semiconductor power device

A power device and lead wire welding technology, applied in the direction of tin feeding device, auxiliary device, welding medium, etc., can solve the problems of excessive diffusion depth, warpage, etc., and achieve small heat-affected area, high reliability, and high current resistance value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

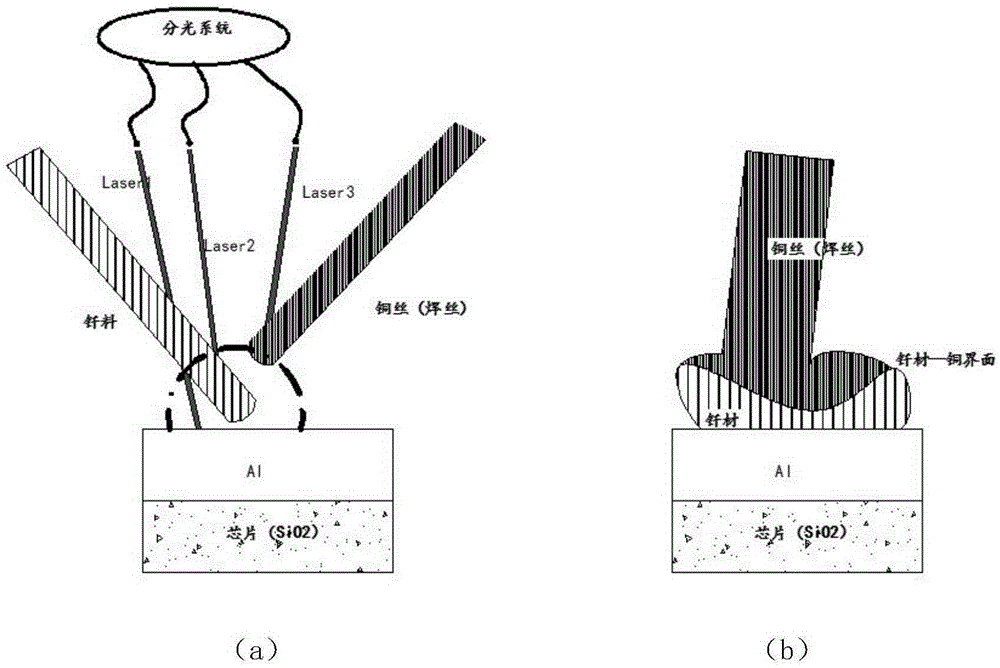

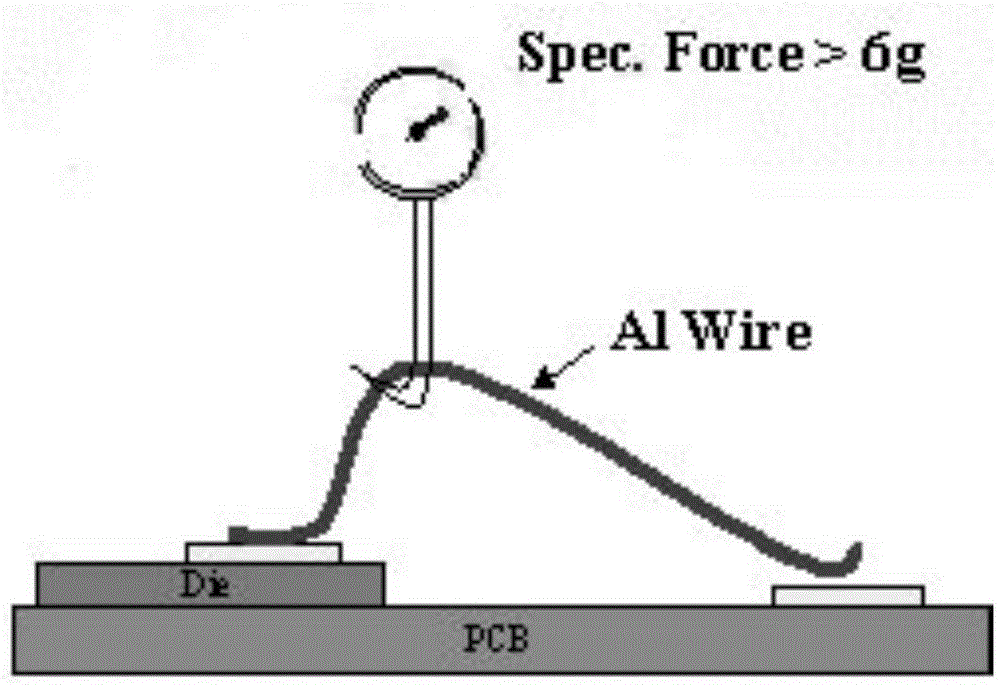

Method used

Image

Examples

Embodiment 1

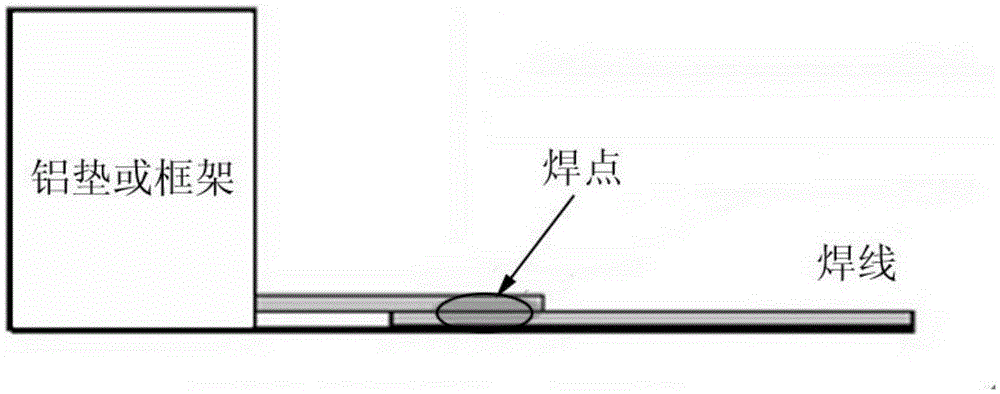

[0094] The present embodiment is the soldering welding of copper wire and chip aluminum pad, and copper wire and frame, and brazing material A is used for welding, and its chemical composition is (wt.%): Sn34.1%, Cu22.4%, Al20%, Ag2.0%, Bi3.5%, Sb9.0%, In9.0%.

[0095] The copper wire and the aluminum pad of the chip are welded to form the first solder joint, the preheating temperature is 220°C, the welding temperature is 290°C, the copper wire is welded to the copper frame to form the second solder joint, the preheating temperature is 220°C, and the welding temperature is 300°C.

Embodiment 2

[0099] The present embodiment is the soldering welding of copper wire and chip aluminum pad, and copper wire and frame, adopts solder A to carry out welding, and its chemical composition is (wt.%): Cu23.1%, Al18.7%, Ag3.5%, Bi3.5%, Sb8.3%, In8.0%, Sn balance.

[0100] The copper wire and the aluminum pad of the chip are welded to form the first solder joint, the preheating temperature is 220°C, the welding temperature is 290°C, the copper wire is welded to the copper frame to form the second solder joint, the preheating temperature is 220°C, and the welding temperature is 300°C.

Embodiment 3

[0104] This embodiment is the soldering welding of aluminum welding wire and chip aluminum pad, and aluminum welding wire and frame, adopts brazing material B to carry out welding, and its chemical composition is (wt.%): Sn34.1%, Cu21.0%, Al23.4%, Ag2.0%, Bi3.5%, Sb8.0%, In8.0%.

[0105] The aluminum wire is welded to the chip aluminum pad to form the first solder joint: the preheating temperature is 220°C, and the welding temperature is 290°C. The aluminum welding wire is welded with the copper frame to form the second solder joint: the preheating temperature is 220°C, and the welding temperature is 300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com