Insert splicing type die

A splicing and mold technology, applied in the field of mechanical forging, can solve problems such as mold wear and tear, achieve the effect of improving mold strength, improving work efficiency, and improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

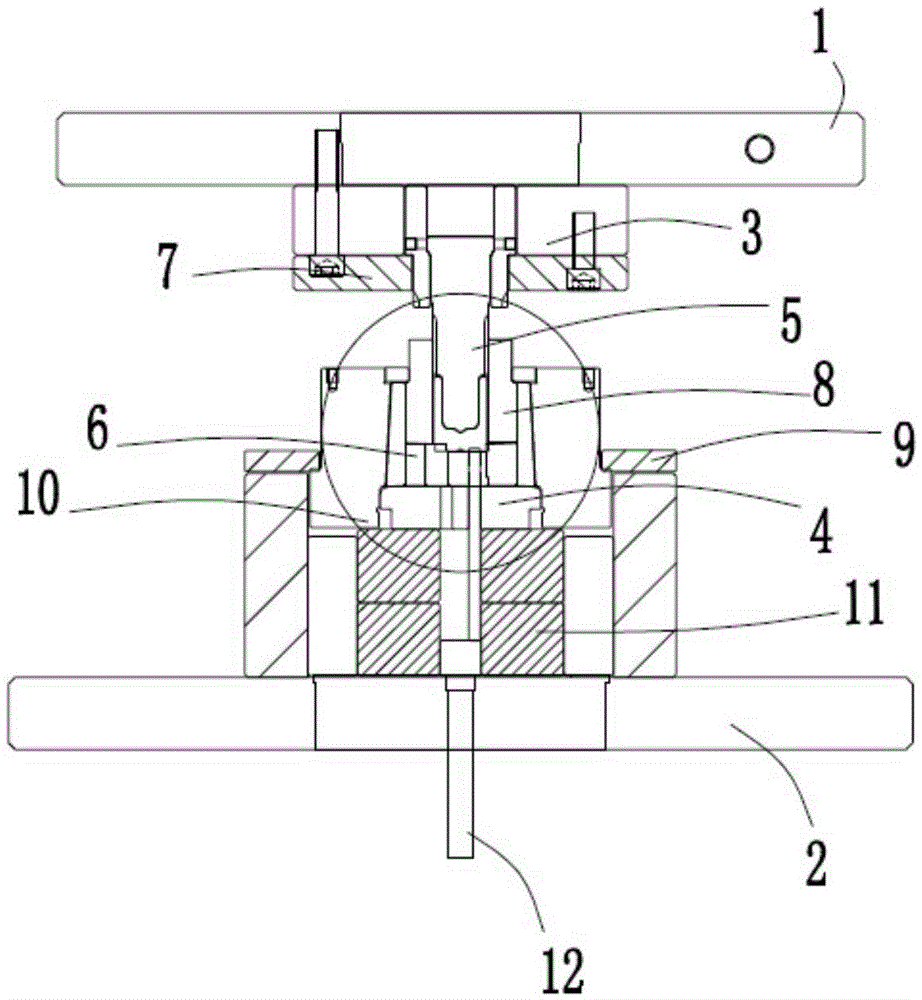

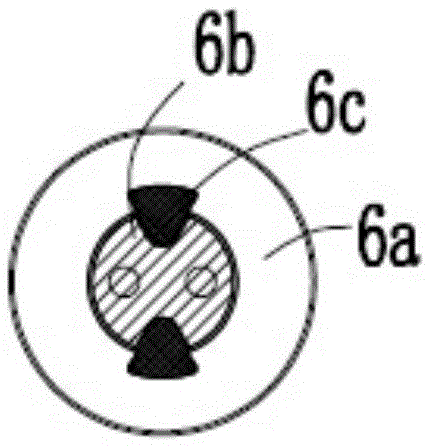

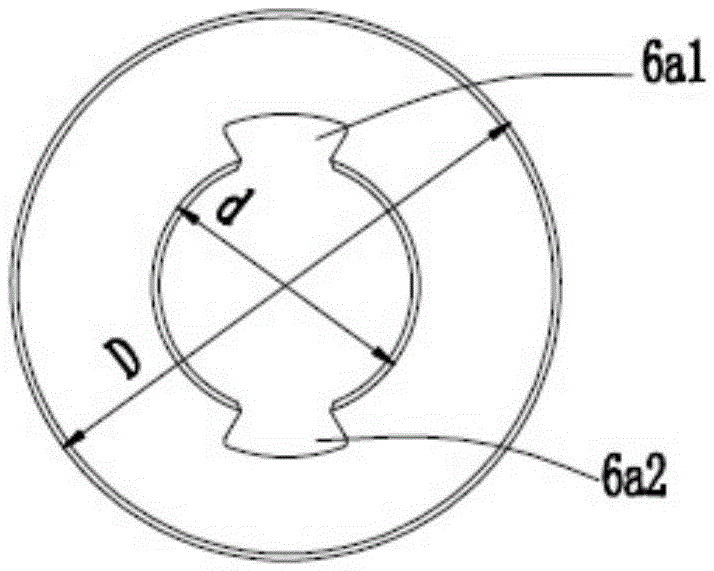

[0028] Picture 1-1 A schematic diagram of a stamping machine for processing piston parts for automobile brakes using an insert splicing mold of the present invention, Figure 1-2 It is a schematic diagram of Embodiment 1 of an insert splicing mold of the present invention, figure 2 It is a schematic diagram of an outer ring mold 6a of an insert splicing mold in Embodiment 1, image 3 It is a schematic diagram of an inner ring mold 6b of an insert splicing mold in Embodiment 1, Figure 4 It is a schematic diagram of the connection key 6c of the insert splicing mold of Embodiment 1. Such as Picture 1-1 , Figure 1-2 , figure 2 , image 3 and Figure 4 As shown, what is provided in this embodiment is an insert splicing mold, including an upper body 1, a lower body 2, an upper mold base 3, a lower mold base 4, an upper mold 5, an insert splicing mold 6, and a fixing plate 7. Side pressure block 8, limit sleeve 9, guide post 10, bearing platform 11 and thimble rod 12. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com