Steel plate surface painting unit with magnetic stirring bar

A technology of magnetic stirring and painting device, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of substandard product quality, uneven paint liquid, easy to produce floating color, etc., and achieve good product quality, Uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

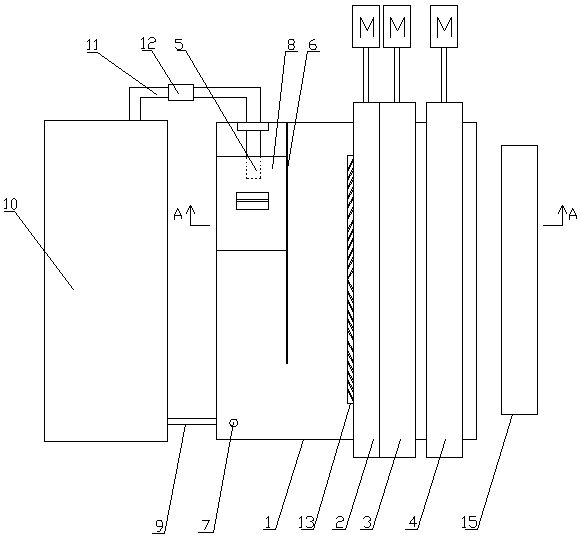

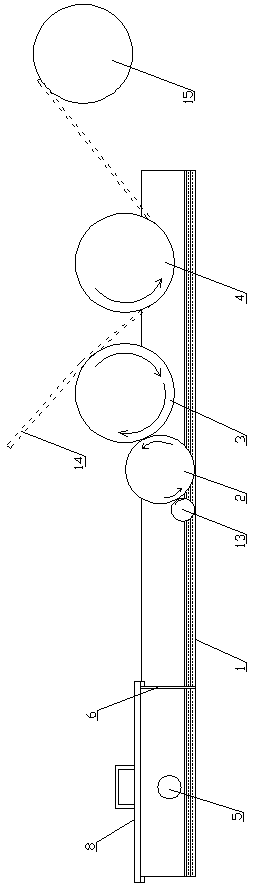

[0019] see figure 1 and figure 2 , the present invention relates to a steel plate surface painting device with a magnetic stirring bar, which includes a paint tank 1, a paint liquid is arranged in the paint tank 1, and steel plates vertically arranged on the paint tank 1 are erected from left to right. Roller 2, rubber roller 3 and backing roller 4, steel roller 2, rubber roller 3 and backing roller 4 are respectively driven by the power device behind them, and the paint tank 1 on the right side of backing roller 4 is provided with a conveying roller 15 , the left end of the rear side plate of the paint tank 1 is introduced into the liquid inlet pipe 5 forward, and the paint tank 1 on the right side of the liquid inlet pipe 5 is provided with a baffle plate 6 arranged forward, and the rear end of the baffle plate 6 Connected to the rear side plate of the paint tank 1, the front end of the baffle plate 6 extends forward and exceeds half of the total length in the front and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com