Thin-wall plastic ultrasonic welded and encapsulated lithium-ion battery pack

A lithium-ion battery pack, ultrasonic welding technology, applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of welding line offset welding surface, poor parts welding, product deformation, etc., to achieve compact structure, packaging Good effect, avoiding the effect of welding line offset welding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

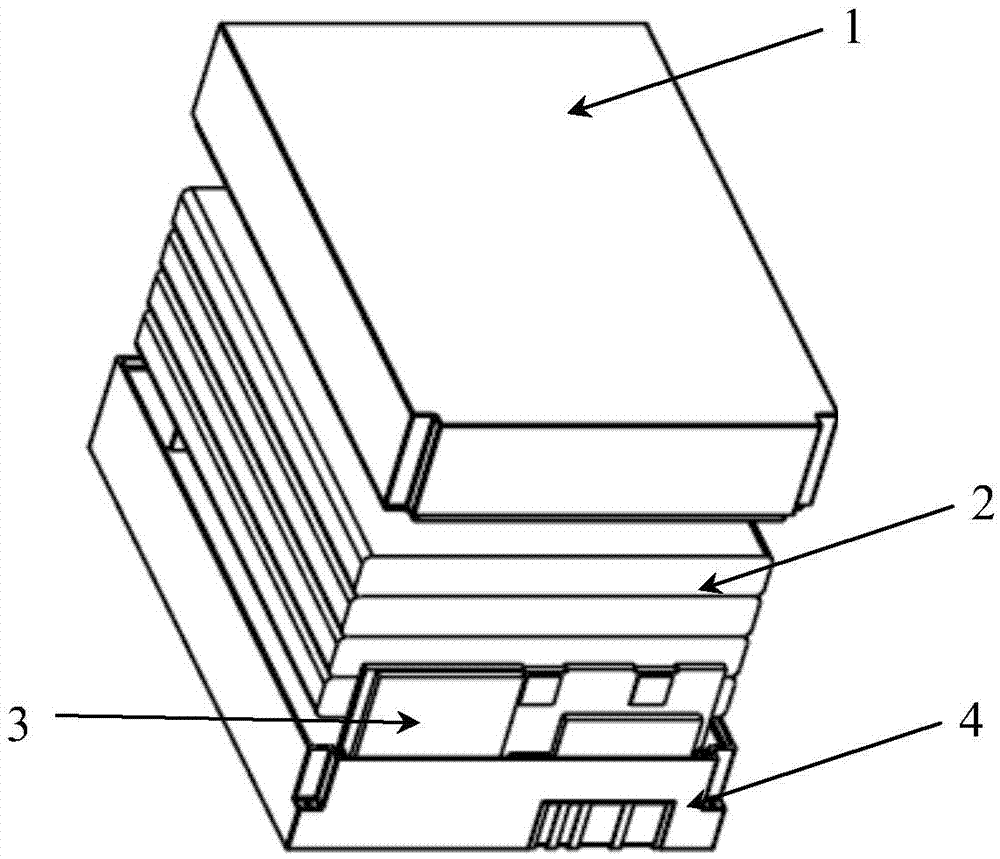

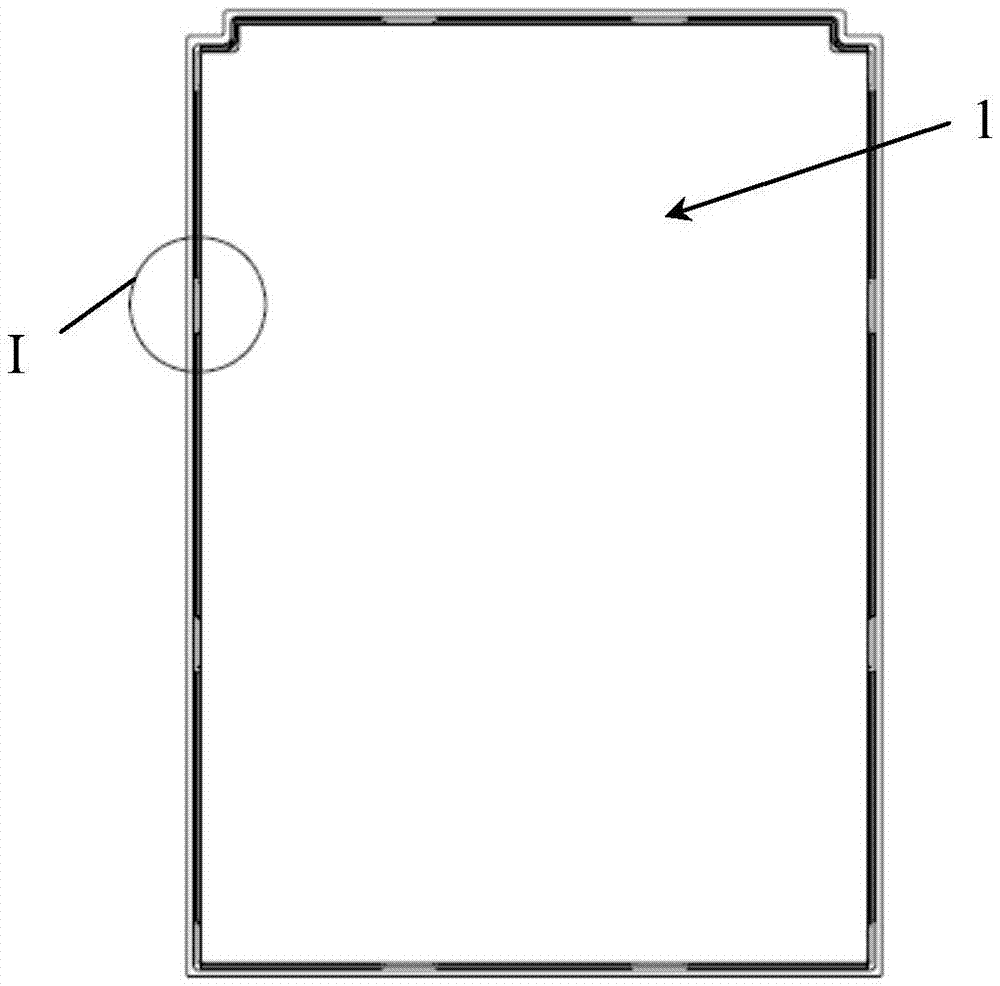

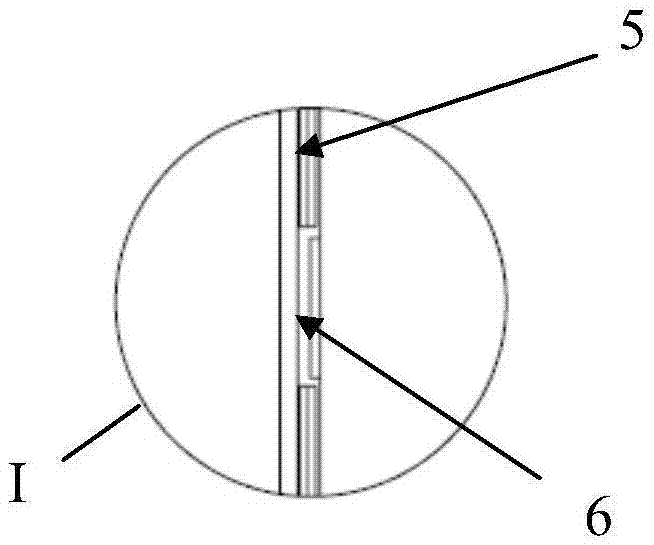

[0026] see Figure 1 to Figure 3 , the present invention provides a lithium-ion battery pack packaged by ultrasonic welding of thin-walled plastics, comprising a hollow upper case 1 and a hollow lower case 4, the upper case 1 is located at the top of the lower case 4, and the upper case 1 It is fastened with the lower shell 4.

[0027] In the present invention, four square single cells 2 are placed on the lower case 4, and the square single cells 2 are connected (connected by soldering) to a protective circuit board 3, and the protective circuit board is installed on on the lower shell 4. In terms of specific implementation, the protection circuit board 3 has an output golden finger as an output interface of the battery pack of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com