Radial multi-coil high-speed electromagnet

A high-speed electromagnet and multi-coil technology, applied in the field of electromagnets, can solve the problems that the temperature of the coil and the iron core cannot be effectively reduced, the middle of the coil and the iron core cannot be cooled, and the magnetic permeability of the magnetic material is reduced, etc. The distribution of the magnetic induction intensity is uniform and the effect of increasing the electromagnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

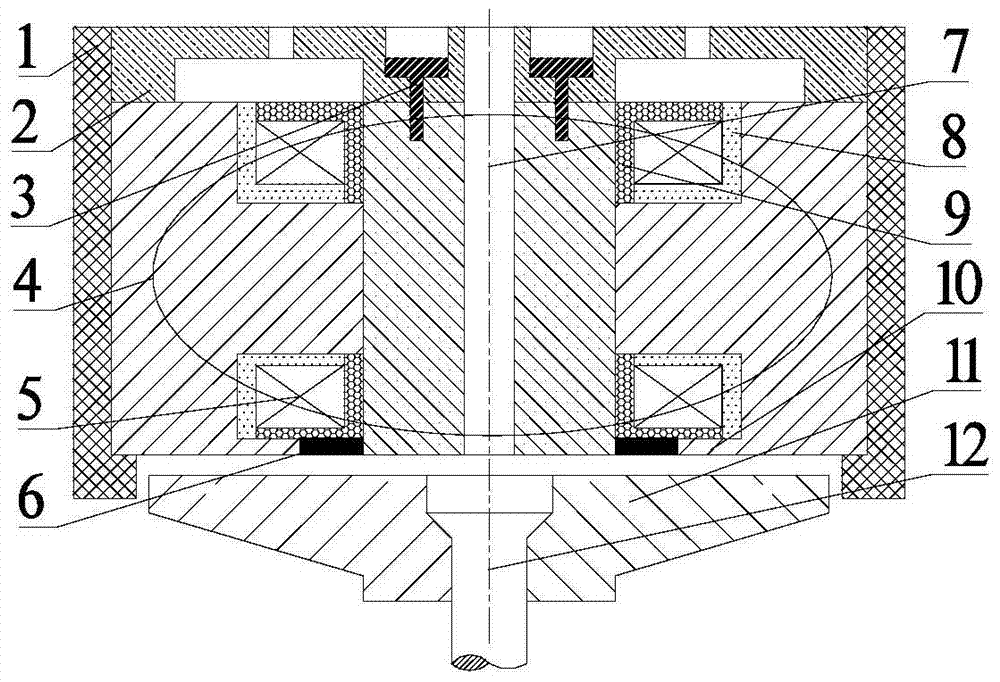

[0028] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

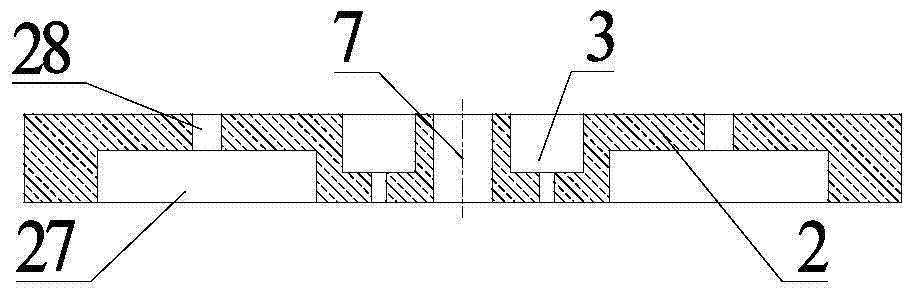

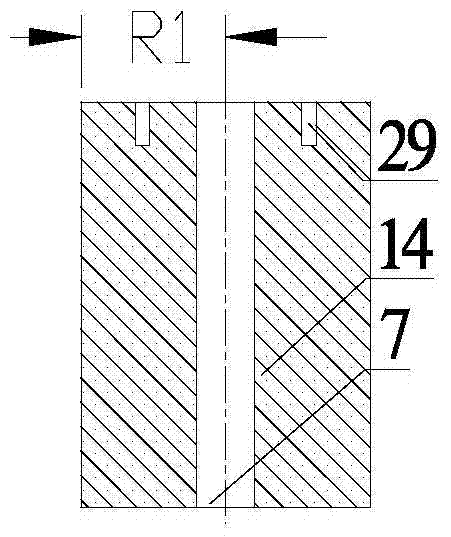

[0029] combine figure 1 , figure 2 , Figure 3(a), Figure 3(b), Figure 4(a), Figure 4(b), Figure 5 The composition of the first embodiment of the radial multi-coil permanent magnet high-speed electromagnet of the present invention includes an outer shell 1, a combined iron core 4, a radial coil 5, an armature 11, a coil skeleton 8, a sealing resin 9 and a valve stem 12. The outer casing 1 is a cylinder with a stepped through hole in the middle, and a fixed large nut 2 is arranged at the upper end; the fixed nut is a cylinder with a through hole center 7, an annular groove 27 on the lower end surface, and a through hole 28 in the center of the groove Body, its upper surface has a countersunk hole 3, and the lower end of the outer side is tapped with threads. The main magnetic pole 14 of the combined iron core is a cylinder with a cylindrical th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com