Double permanent magnet high speed two-way electromagnet

A high-speed electromagnet and electromagnet technology, which is applied in the field of electromagnets, can solve problems such as the decrease in the reliability and life of solenoid valves, the decrease in the magnetic permeability of magnetic materials, and the increase in heat generation of coils, etc., to achieve uniform distribution of magnetic induction intensity and increase magnetic induction. The number of lines, the effect of increasing the electromagnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

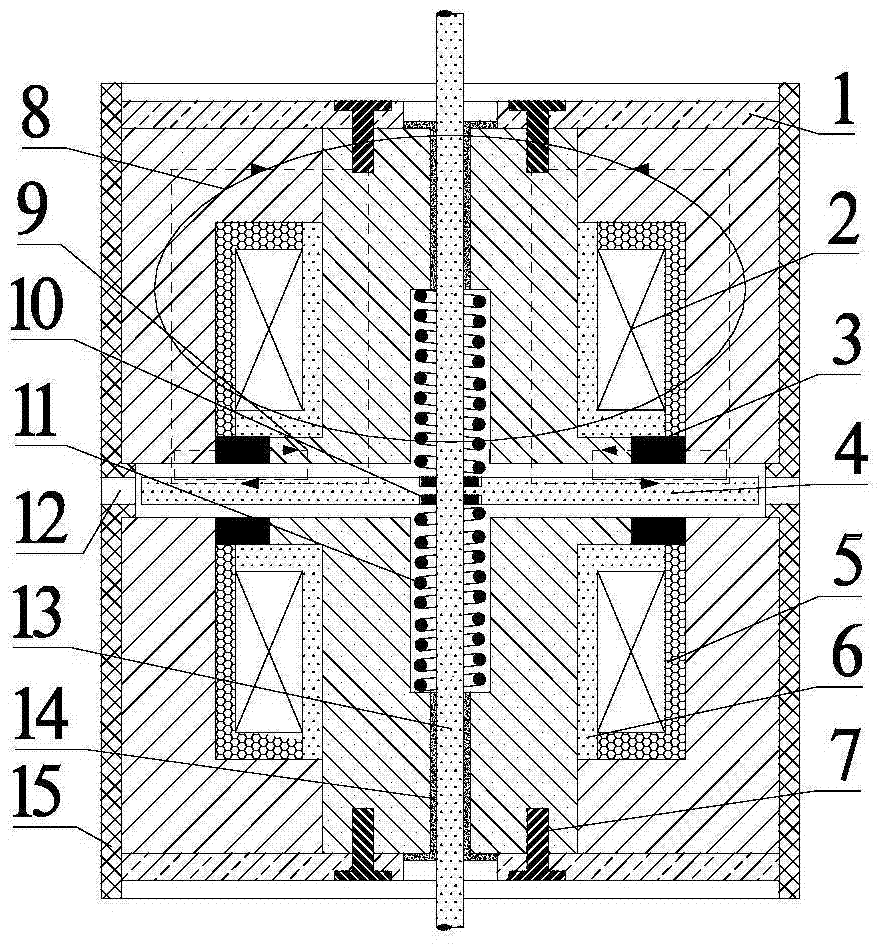

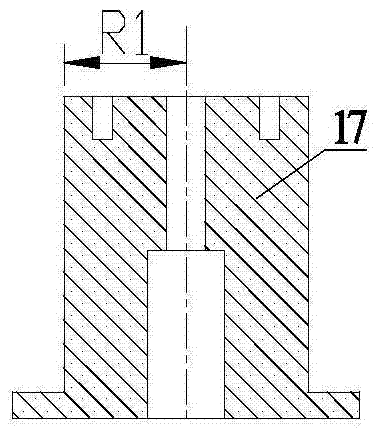

[0027] combine figure 1 , figure 2 , image 3 , Fig. 4 (a), Fig. 4 (b), Fig. 4 (c), the composition of double permanent magnet Japanese type high-speed two-way electromagnet first embodiment of the present invention comprises outer casing 15, Japanese type iron core 8, coil 2. Coil bobbin 6, sealing resin 5, return spring 11, embedded valve sleeve 14, armature 4 and valve stem 13. The Japanese-shaped iron core 8 is composed of the main magnetic pole 17, the auxiliary magnetic pole 16 and the permanent magnet 3, and the two groups are symmetrically distributed on both sides of the armature; the main magnetic pole 17 is a cylindrical structure with a stepped through hole in the center, and a belt The small hole of the screw thread, the auxiliary magnetic pole 16 is a cylinder with a stepped through hole, and the radius R1 of the main magnetic pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com