The determination method of planetary gear system and its structural parameters

A technology for planetary gears and determination methods, applied in belts/chains/gears, electrical digital data processing, special data processing applications, etc., can solve problems such as expensive wear-resistant materials or oil-absorbing materials, poor environmental protection, and environmental pollution, and achieve Increased service life, low cost, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

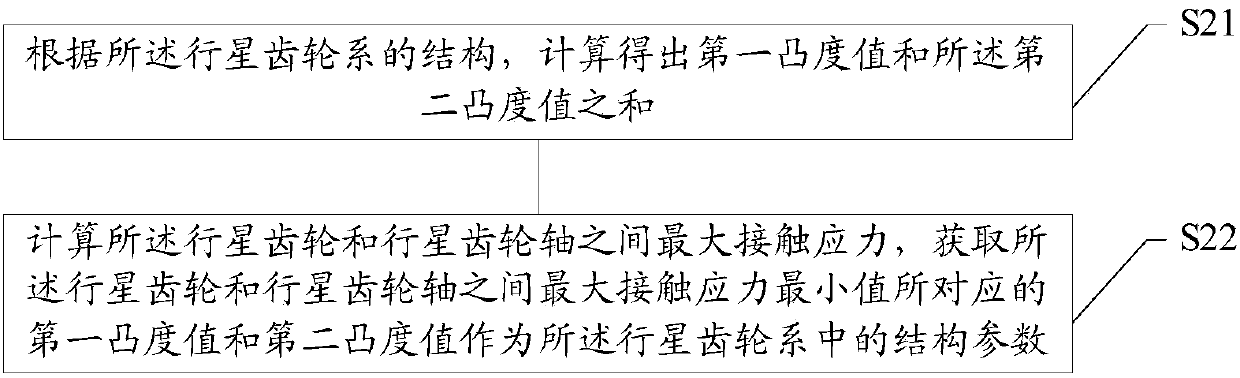

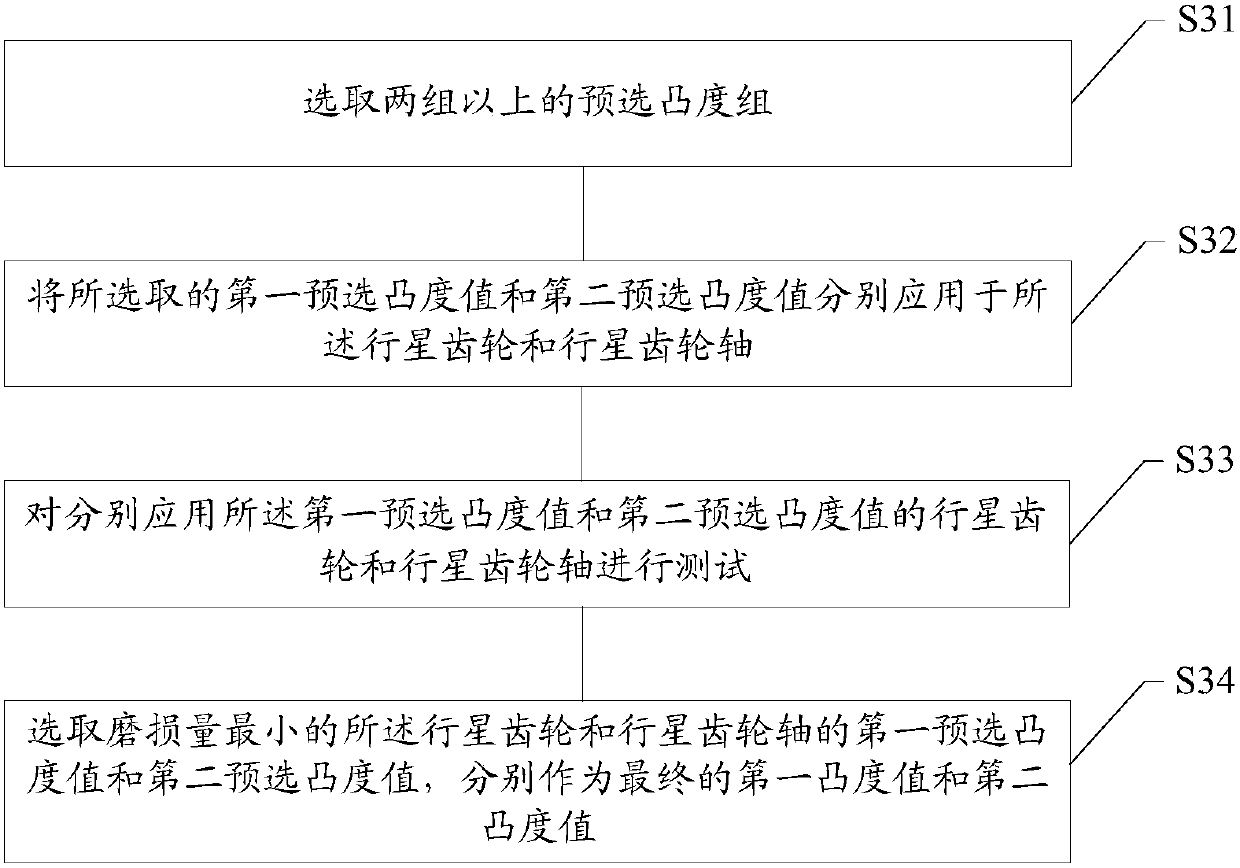

[0039] In order to solve the above-mentioned problems in the prior art, the technical solution adopted in the embodiment of the present invention is to set the shaft hole of the planetary gear and the part of the outer surface of the planetary gear shaft that can be in contact with the inner wall of the shaft hole in an arc shape. , can effectively reduce the friction between the planetary gear and the planetary gear shaft, improve the service life of the planetary gear system, low cost, environmentally friendly and durable.

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

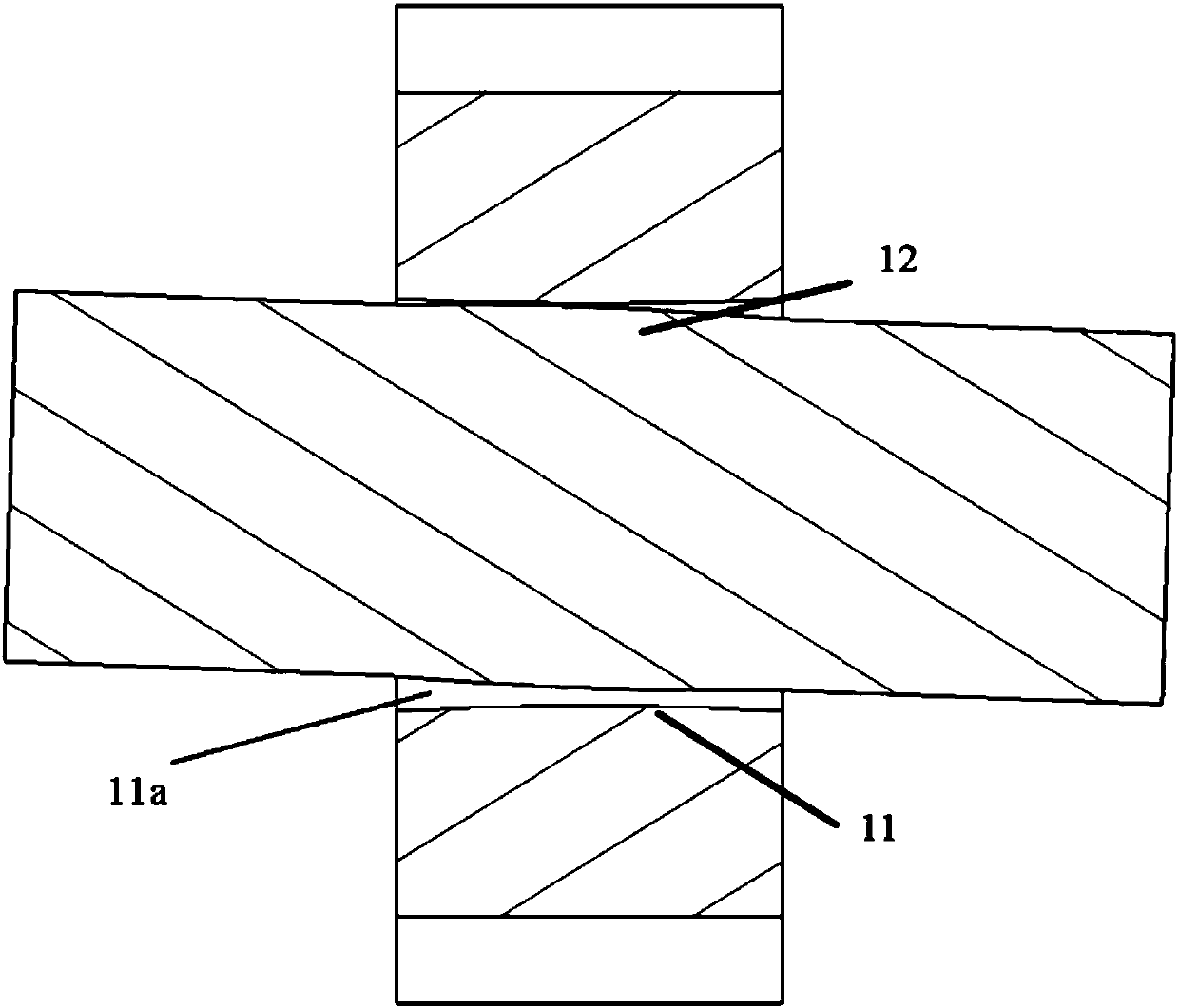

[0041] figure 1 A schematic structural diagram of a planetary gear system in an embodiment of the present invention is shown. Such as figure 1 The planetary gear system shown can include:

[0042] The planetary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com