Integrated ferrule four-point contact ball bearing

A four-point contact, integral technology, applied in the field of bearings, can solve the problems of difficult design and manufacture, reduced fit, low ball bearings, etc., to reduce the maximum contact stress, improve fatigue life, and reduce radial loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

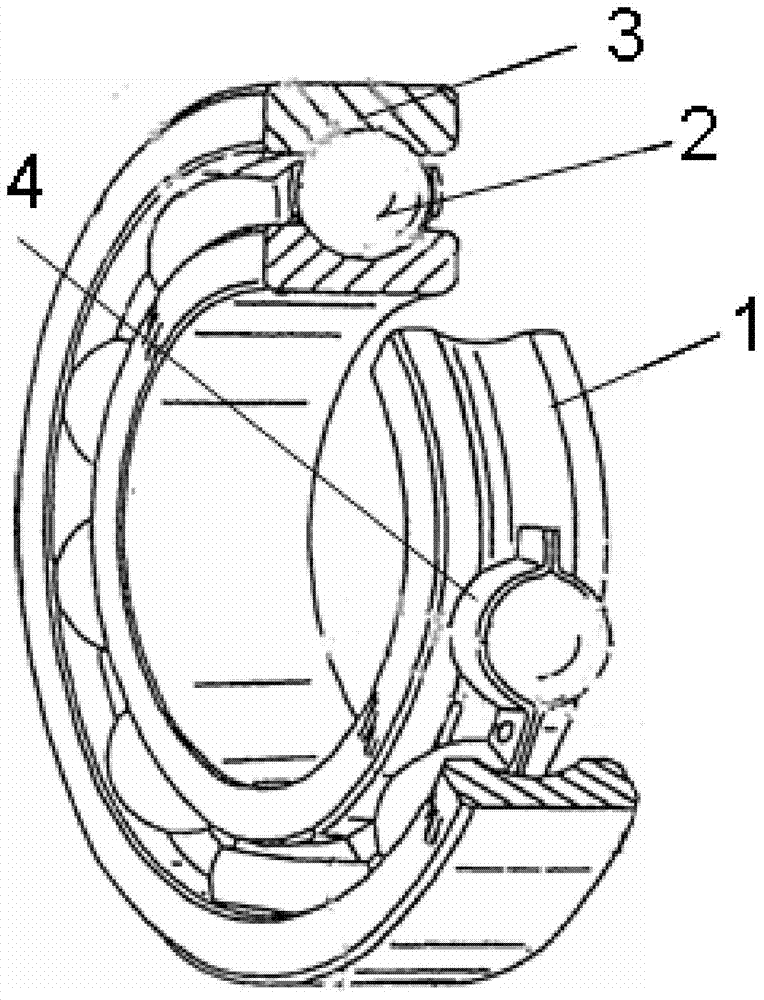

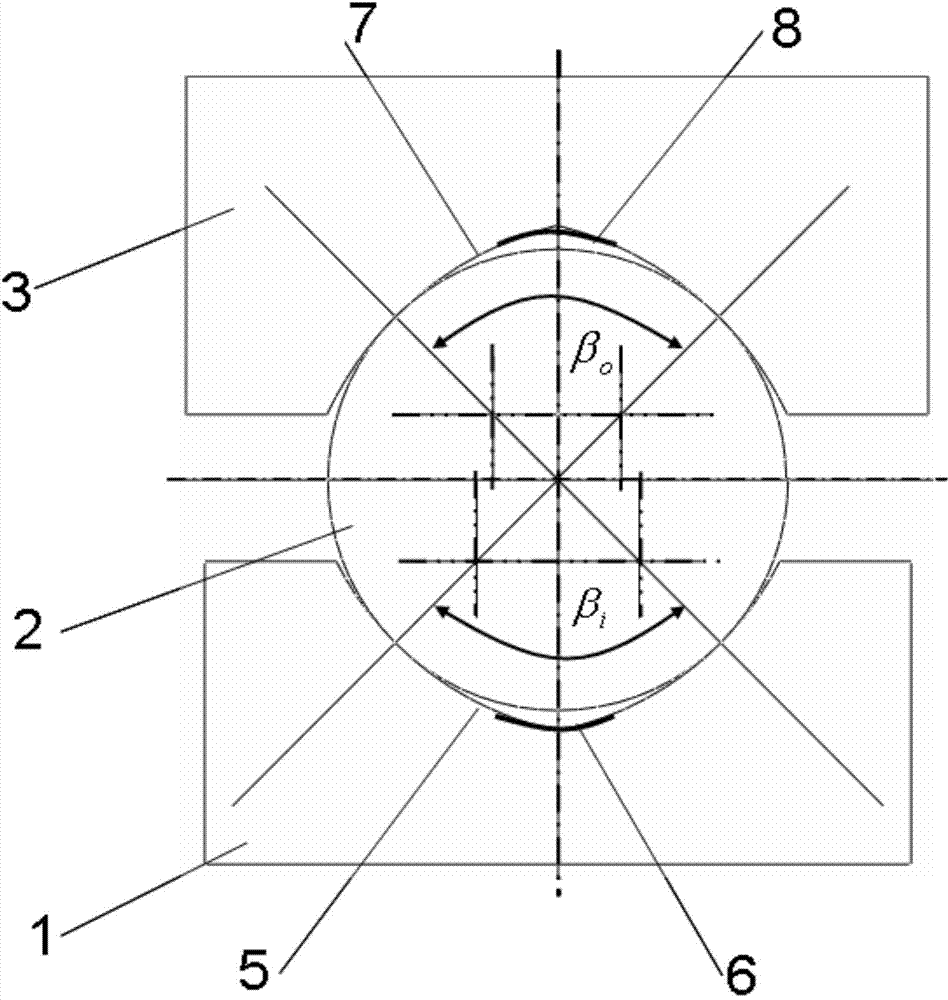

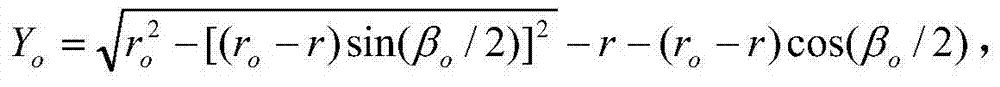

[0022] Integral ferrule four-point contact ball bearing includes inner ring 1, balls 2, outer ring 3 and cage 4, balls 2 are evenly distributed between the inner ring 1 annular raceway and outer ring 3 annular raceway in the circumferential direction of the cage , there is a radial gap between the ball 2 and the inner ring 1 and the outer ring 3; the cross-sectional profiles of the inner ring 1 and the outer ring 3 are composed of three curves, two of which are symmetrical to the radial axis of the ball 2 , the other curve is a connecting line between two curves symmetrical to the radial axis of the ball 2, the connecting line is tangent to the connected two curves symmetrical to the radial axis of the ball 2 at the connecting point, and the connecting line is One of arc curve, elliptic curve, cycloid, hyperbola and sine curve; two curves symmetrical to the radial axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com