A profilogram numerical control code generation method based on the genetic algorithm and a numerical control machine tool thereof

A contour curve and genetic algorithm technology, applied in the genetic algorithm-based numerical control code generation method for contour curves and the field of numerical control machine tools, can solve the problems of cumbersome processing procedures, complicated operations, and difficulty in direct implementation, and improve work efficiency and quality. High processing precision, simple and direct operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

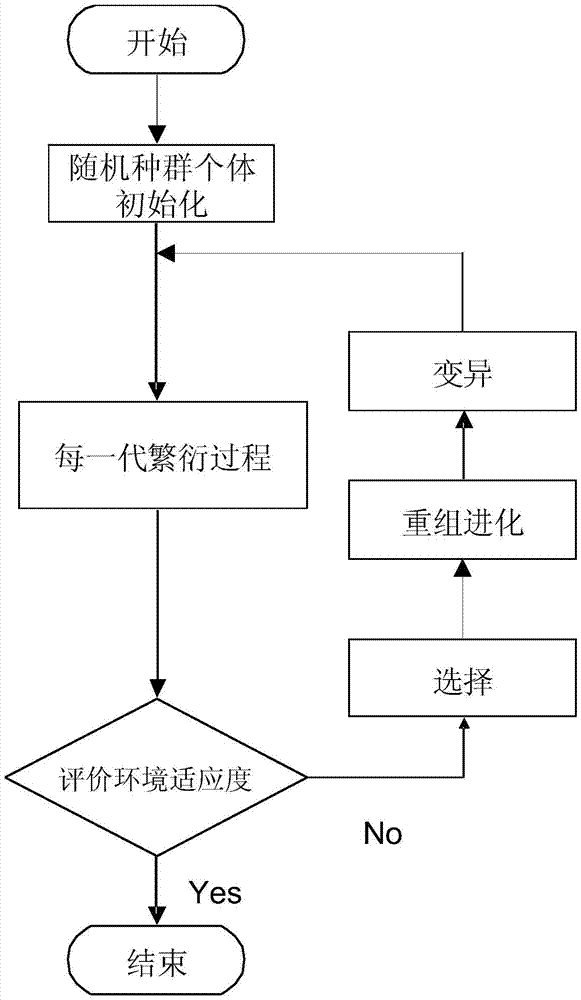

[0046] A method for generating NC codes for contour curves based on a genetic algorithm is used for a NC machine tool, including the following processing steps:

[0047] (1) Establish a mathematical model for the contour curve of the workpiece in the numerical control system;

[0048] (2) The genetic algorithm is programmed in the computer for iterative calculation to obtain an effective approximation node;

[0049] (3) Generate and output the numerical control code of the tool position track of the machining surface of the machining tool;

[0050] (4) Put the workpiece into the processing table, and fix it through the fixture;

[0051] (5) The tool is set out from the tool magazine, and the starting point of processing is positioned;

[0052] (6) The machining tool processes the machining workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com