Dryer

A dryer and drying tunnel technology, applied in dryers, drying, marine product drying, etc., to achieve the effects of convenient cleaning, stable air supply, and reduced drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

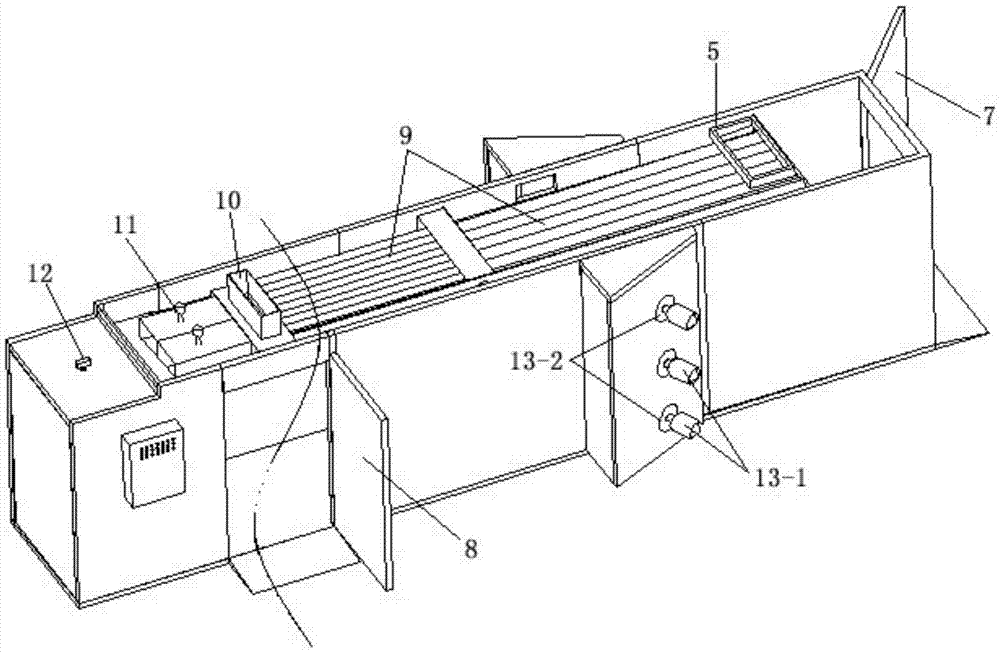

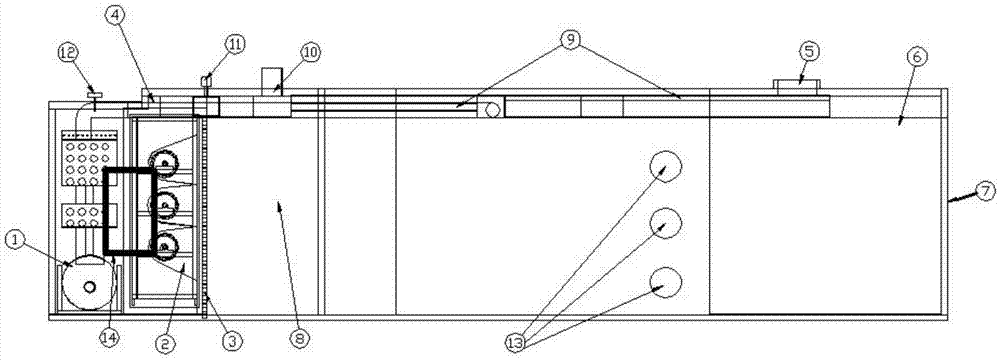

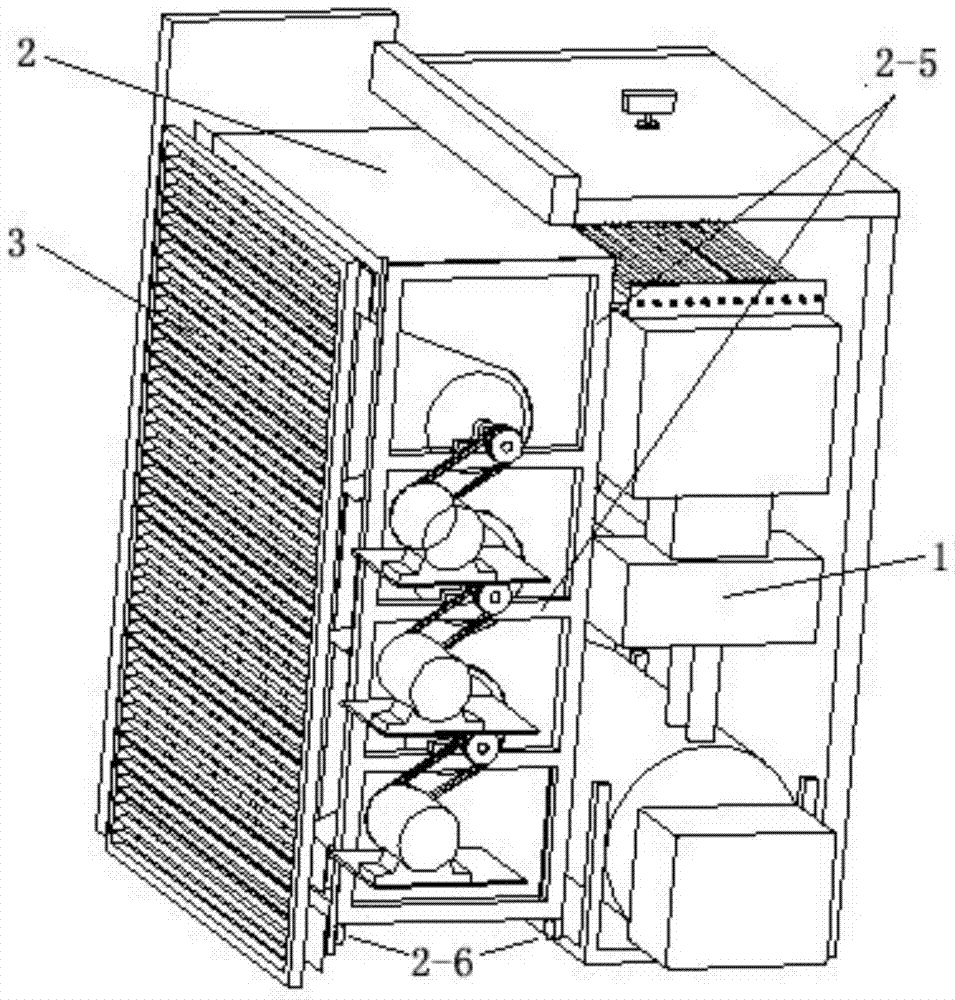

[0031] Embodiment: refer to attached Figure 1-9 , a kind of drying machine, comprises the shell of drying machine that inner wall is provided with insulation layer, air heating room, air supply room, drying tunnel, the air inlet 5 that communicates with air heating room, the air outlet 6 that communicates with the front end of drying tunnel, set The feed port 7 at the front end of the drying tunnel, the discharge port 8 at the rear end of the drying tunnel, a heat source heat exchanger 1 is provided in the air heating chamber, and a direct blowing air supply device 2 is provided in the air supply chamber. Type air supply device 2 comprises driving device 2-1, air channel plate 2-2, clapboard 2-3, centrifugal wind wheel 2-4, and one end of air channel plate 2-2 is arc-shaped, and the other end is an opening and External expansion; the centrifugal wind wheel 2-4 is set at the arc center of the air duct plate 2-2; the partition plate 2-3 is set on both sides of the end face of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com