Bed body structure of Raschel loom

A warp knitting machine and bed technology, which is applied in the field of the bed structure of the less-bar Raschel warp knitting machine, can solve the problems of complicated structure, failure to ensure the effective strength and rigidity of the bed structure, and increase in manufacturing cost, and achieves Good strength and rigidity, ensure the installation size, and the effect of reliable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

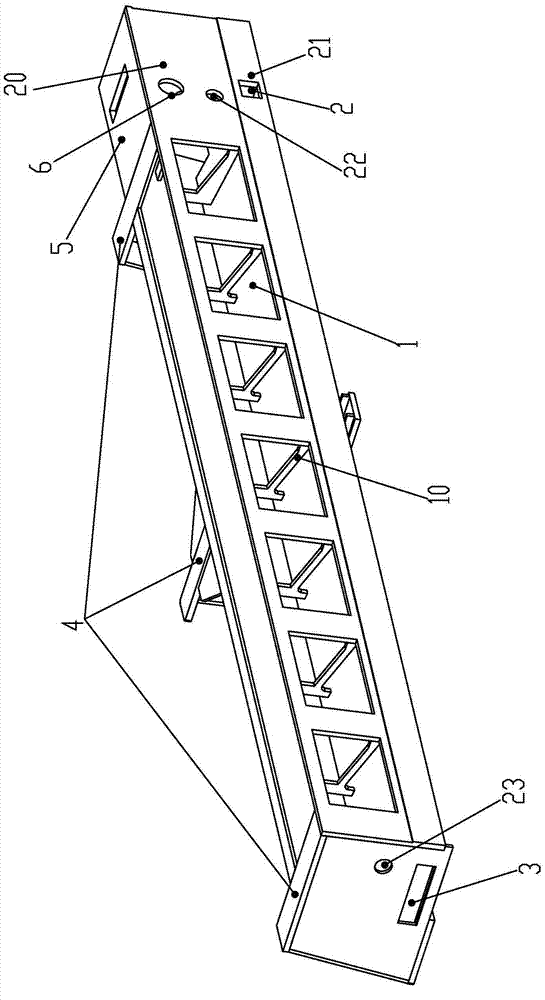

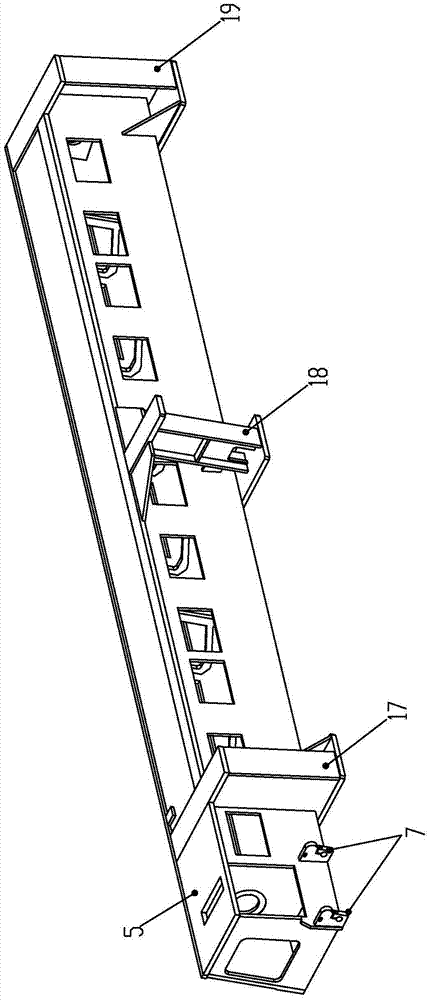

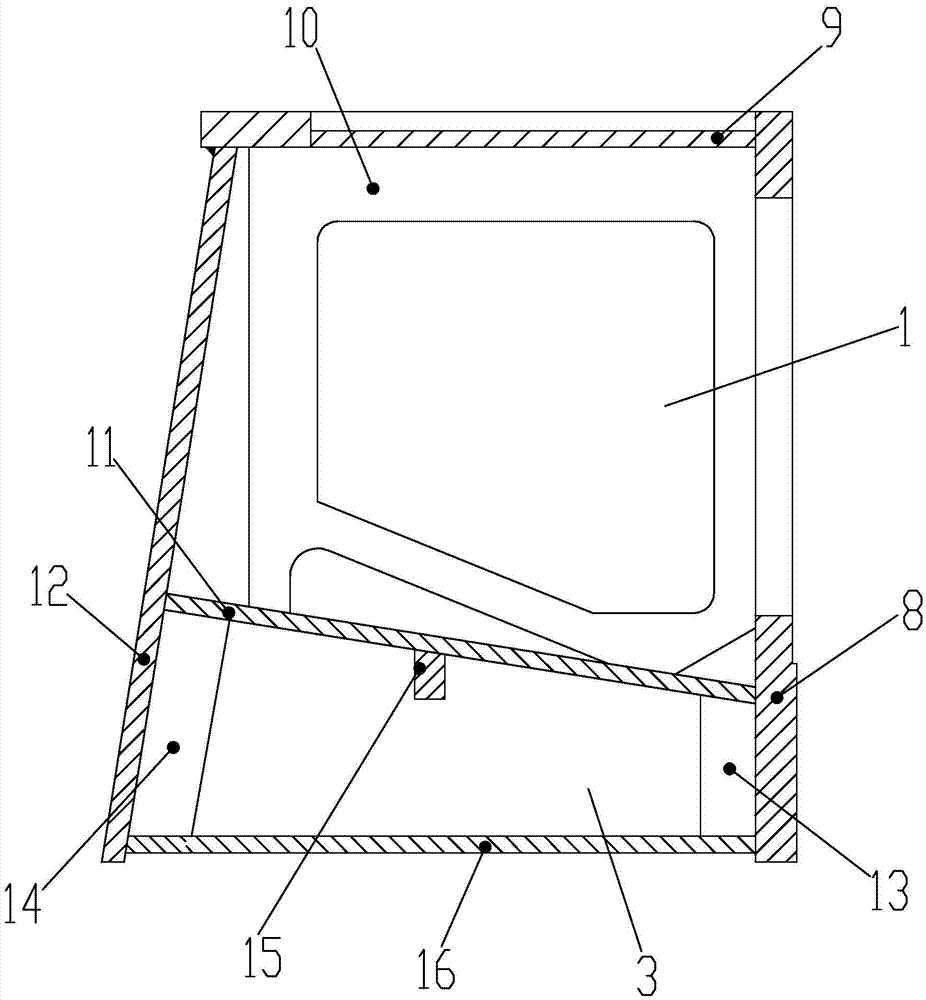

[0024] Such as Figure 1-4 As shown, the bed structure of a Raschel warp knitting machine of the present invention includes a bed body, and the bed body is provided with an oil tank structure one 1, an oil tank structure two 2, a sand box structure 3, a frame support structure 4, a comb Bar traversing support structure 5, hydraulic element installation structure 6 and main motor seat installation structure 7. The frame support structure 4 is located at the front, middle and rear of the bed body, the main motor seat installation structure 7 is located at the back of the bed body, the fuel tank structure 1 is located at the upper part of the bed body, and the sand box structure 3 is located at the fuel tank structure One of 1 below.

[0025] The bed body includes a front part and a rear part, and the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com