Heating device for evaporation and evaporation equipment

A heating device and evaporation technology, which are applied in the directions of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of uneven heating, performance deterioration, and easy spraying of evaporation materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

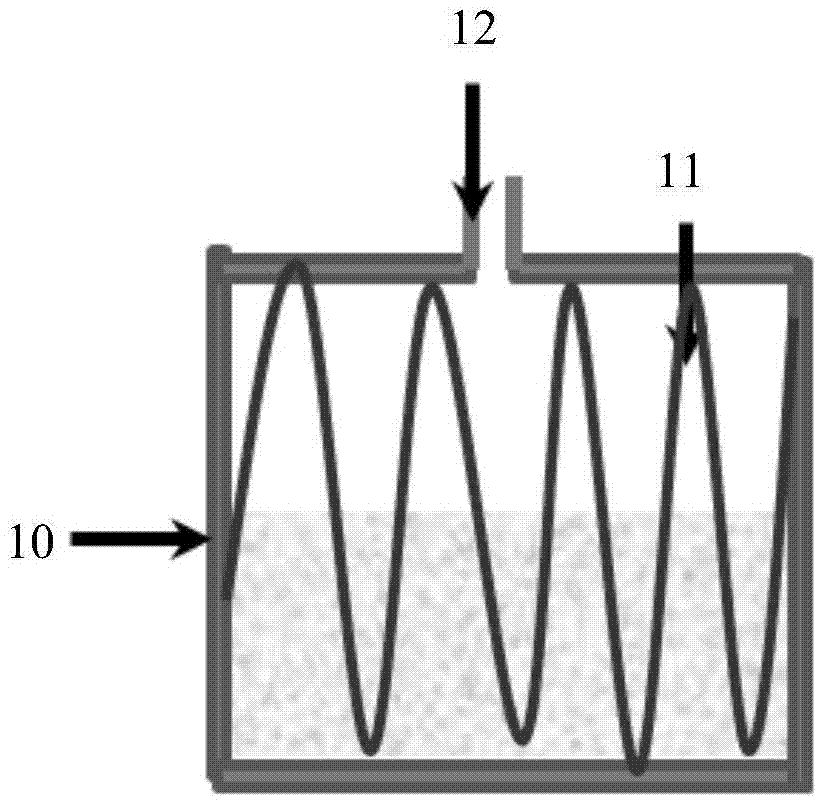

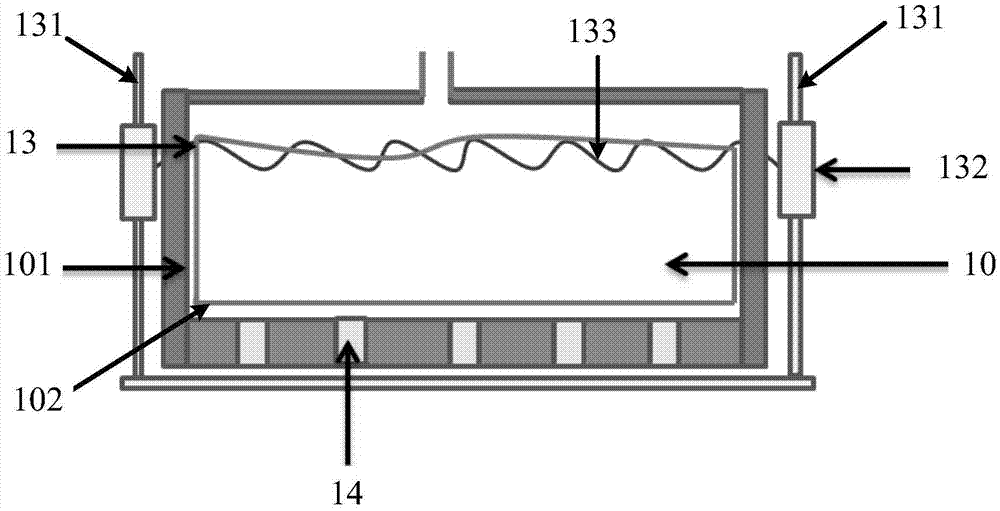

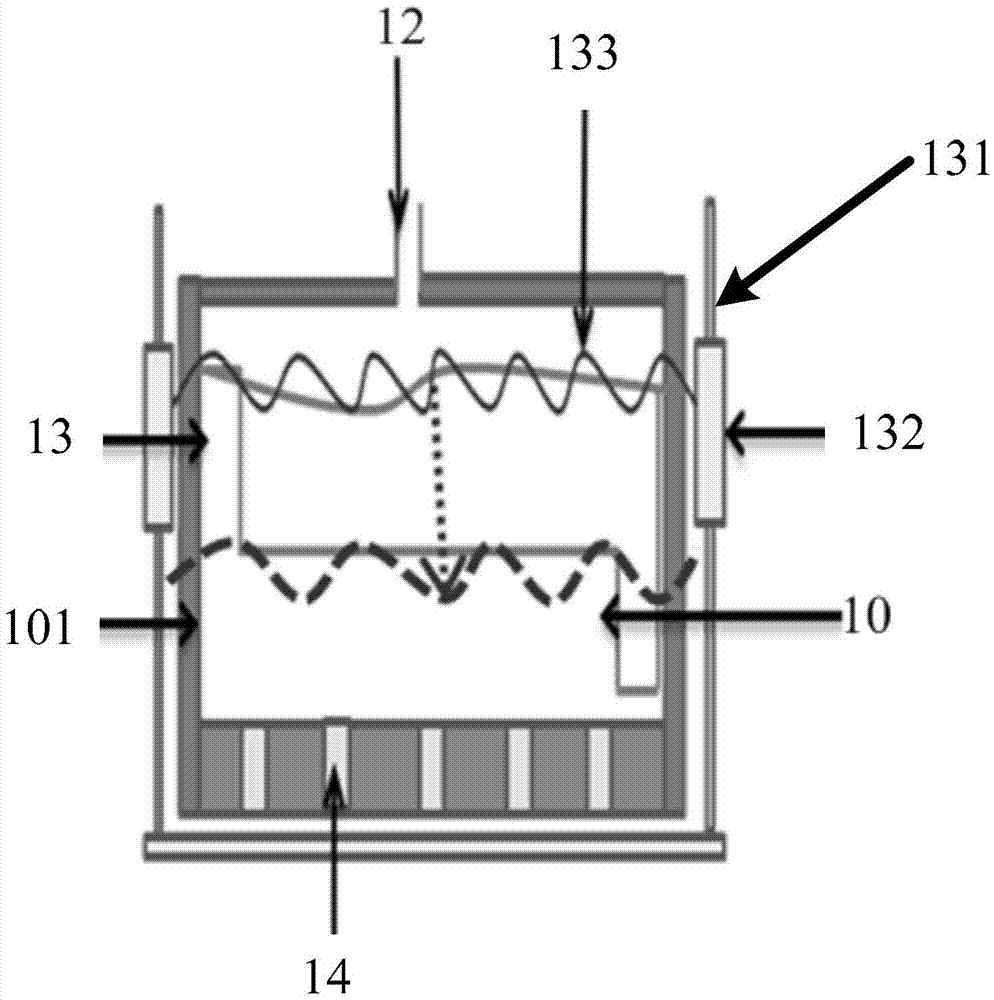

[0027] The invention provides a heating device and evaporation equipment for evaporation, which solves the problems that the existing evaporation equipment is unevenly heated, the evaporation material is easy to spray, the performance is easy to deteriorate, and the adjustment of the evaporation deposition rate is not suitable for stability.

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0029] An embodiment of the present invention provides a heating device for evaporation, such as figure 2 As shown, the device includes: a crucible 10 for containing the evaporation raw materials; a movable heating unit 13 arranged outside the crucible 10 and higher than the top of the evaporation raw materials during evaporation; a weighing sensor device 14 arranged on The bottom of the crucible 10 is used to weigh and output the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com