Novel textile drying device

A drying device and textile technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of inability to dry textiles, affect the drying efficiency of textiles, etc., achieve strong practicability and applicability, improve drying The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

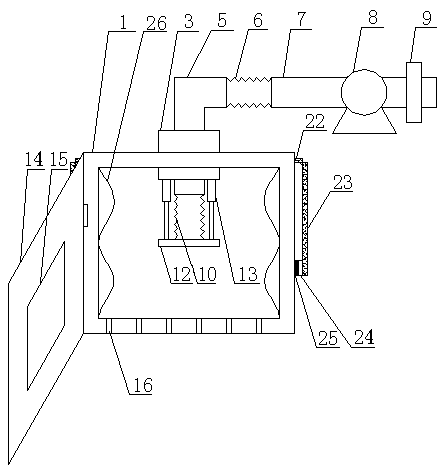

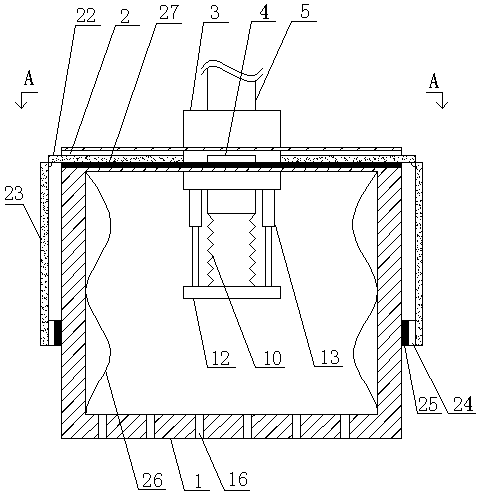

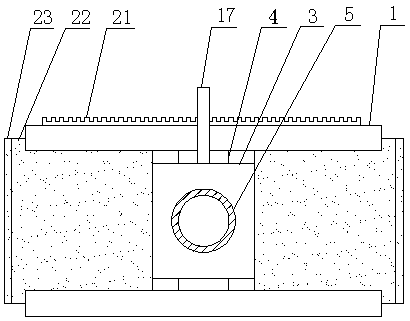

[0022] Such as Figure 1 to Figure 6 As shown, a new type of textile drying device includes a box body 1, a chute 2 penetrating left and right is arranged on the top plate of the box body, and a slider 3 is slidably connected to the inside of the chute, and the front and rear sides of the slider block Sliding plates 4 are fixedly connected respectively, and cover plates are fixedly connected to the left and right sides respectively. The sliding plates and cover plates cooperate with the chute respectively, and an air inlet pipe 5 runs through the inside of the slider, and the air inlet pipe The upper end is connected with a corrugated pipe A6, the corrugated pipe A is connected with a connecting pipe 7, the connecting pipe is provided with a fan 8 and an air heater 9, and the lower end of the air inlet pipe extends into the inside of the box and is connected with a corrugated Pipe B10, the outer periphery of the end of the bellows B is fixed on the fixed plate 12 with the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com