Automatic food frying device

An automatic turning and food technology, applied in food processing, food science, application, etc., can solve the problems of uneven heating of food, poor stir-frying effect, etc., and achieve the effect of strong practicability, good effect, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

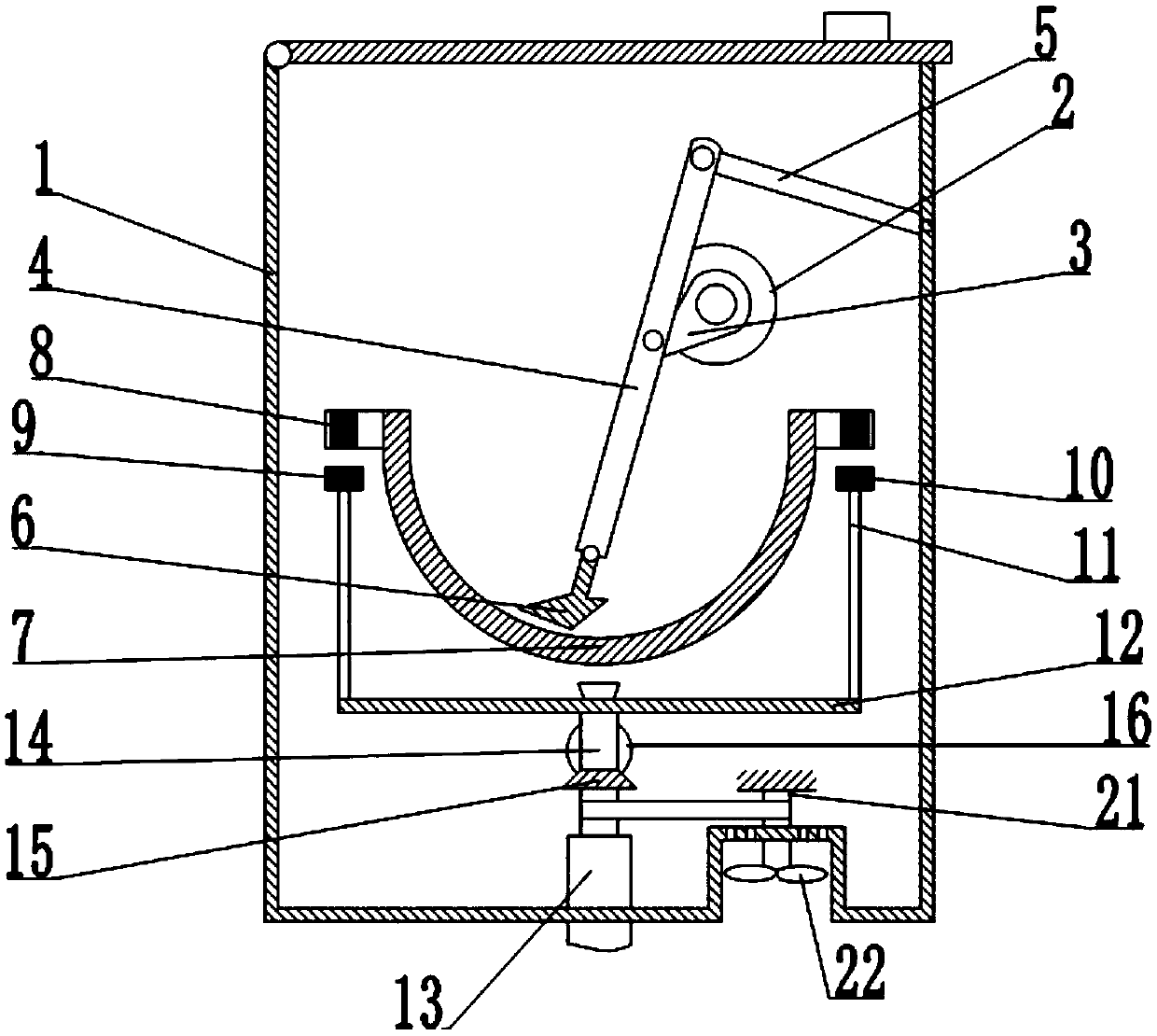

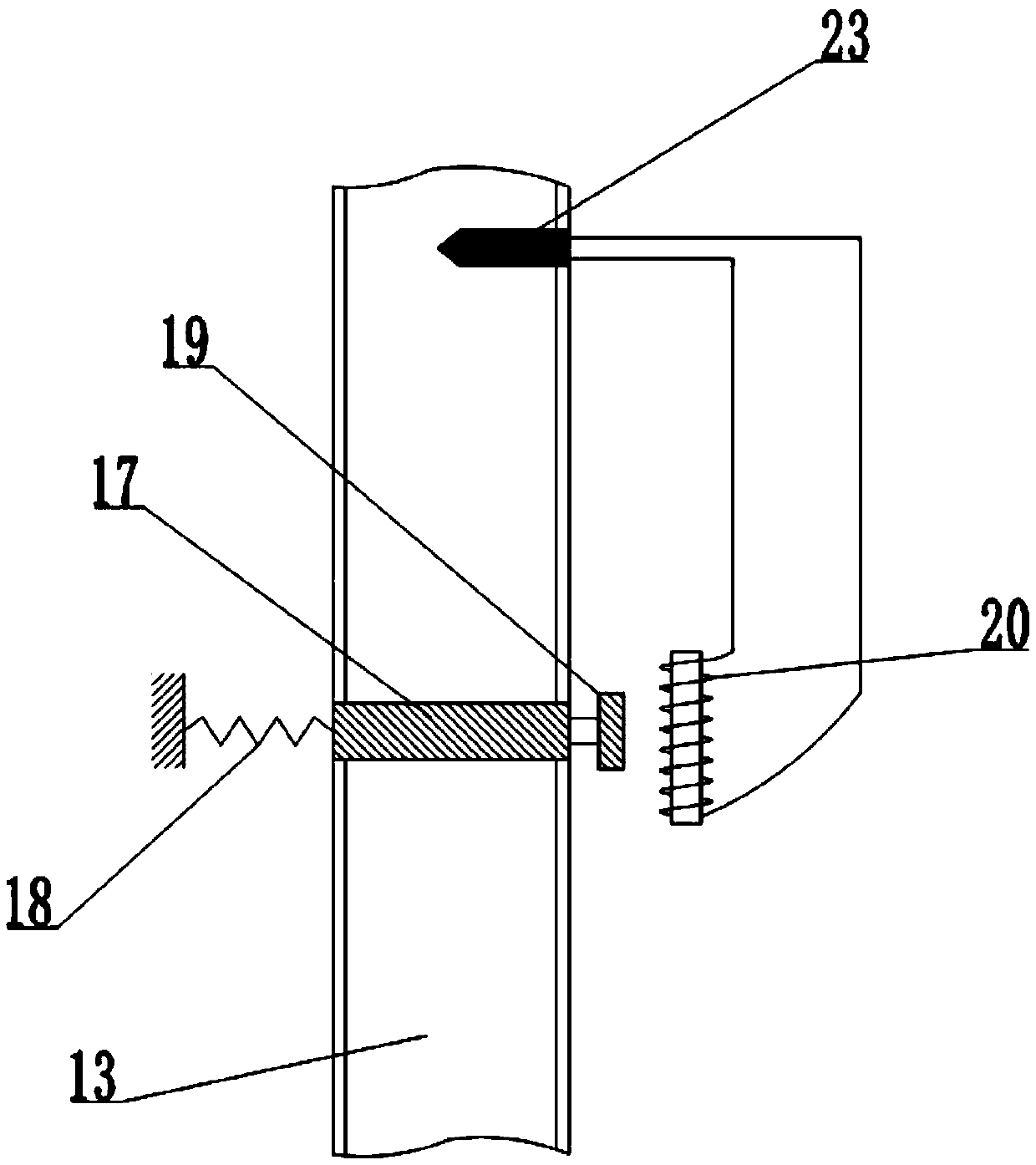

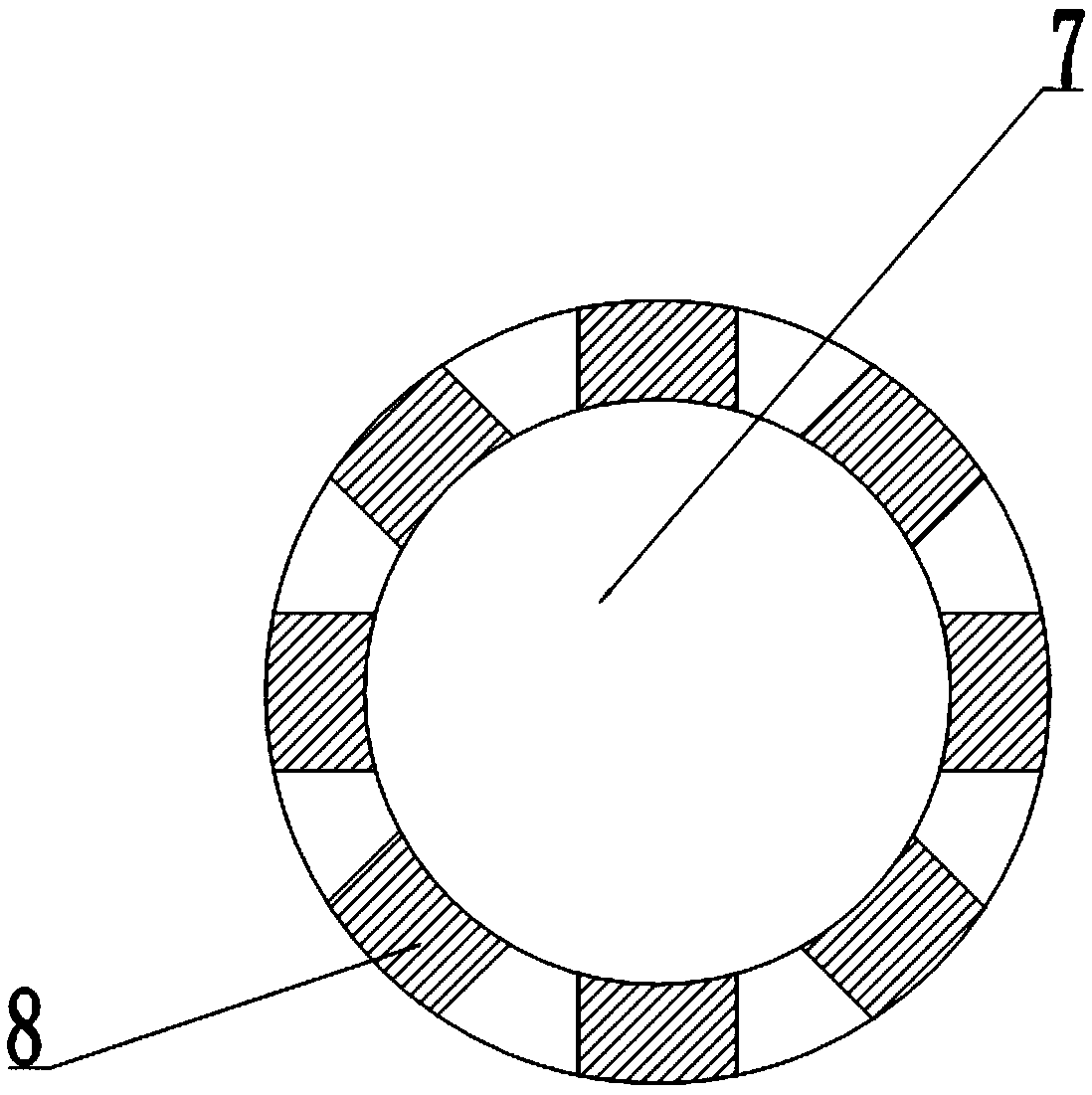

[0020] The reference signs in the accompanying drawings of the description include: chassis 1, motor 2, rocker 3, swing lever 4, connecting rod 5, shovel 6, stir frying pan 7, first magnet block 8, second magnet block 9, third Magnet block 10, vertical rod 11, rotating plate 12, air supply pipe 13, rotating pipe 14, first bevel gear 15, second bevel gear 16, baffle plate 17, spring 18, iron block 19, solenoid 20, rotating rod 21, fan blade 22, thermocouple sensing needle 23.

[0021] The embodiment is basically as attached Figure 1 to Figure 3 As shown: the automatic food stir-frying device of the present invention includes a cabinet 1, a cover plate is hinged on the top of the cabinet 1, and a handle is fixedly installed on the cover plate.

[0022] The motor 2 is fixedly connected to the chassis 1, the output shaft of the motor 2 is fixedly connected to the rocker 3, the rocker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com