Co-emulsifier and preparation method therefor, emulsifier composition and application thereof, and oil-based drilling fluid

A technology of auxiliary emulsifier and emulsifier, which is applied in the field of oil-based drilling fluid, can solve the problems that cannot meet the requirements of high-density oil-based drilling fluid, the strength of the emulsified film is not enough, and the temperature resistance cannot meet the field requirements, etc., and achieve cheap and stable sources Performance enhancement, good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

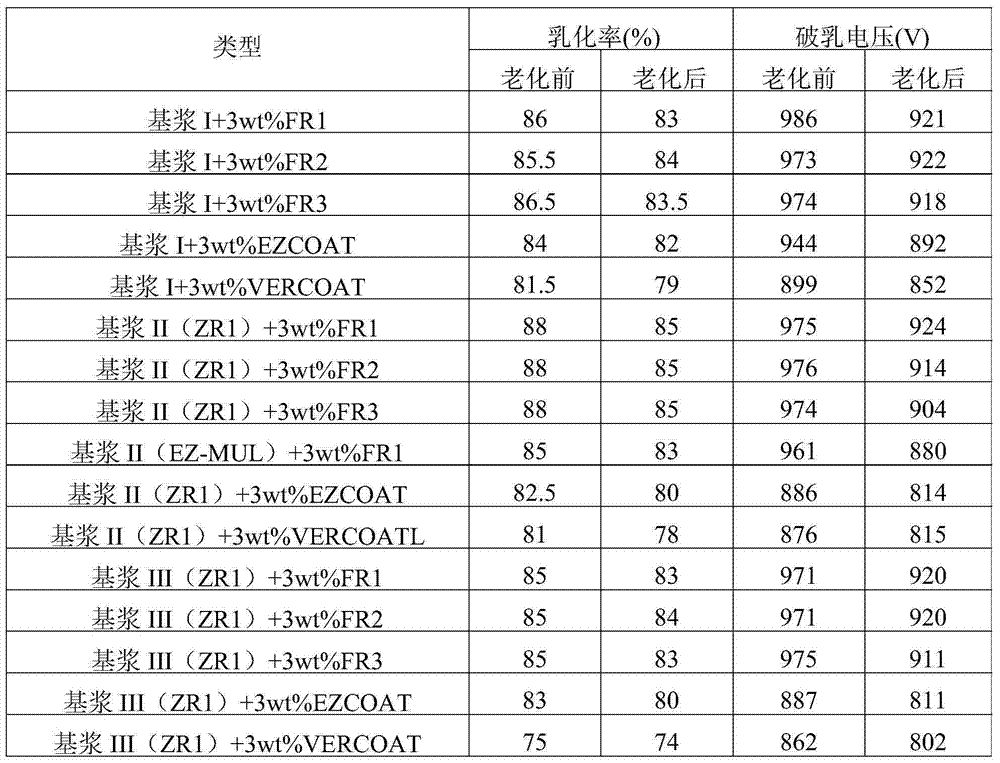

Examples

Embodiment approach

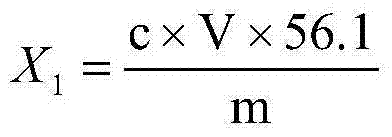

[0018] According to the co-emulsifier provided by the present invention, although as long as it is ensured that the co-emulsifier contains at least two amide groups and at least one hydrocarbon group comprising 7-30 carbon atoms, a better emulsifying effect can be obtained, and it has a higher resistance to emulsification. temperature stability. According to a preferred embodiment of the present invention, the co-emulsifier is prepared according to the following method: performing a first amidation reaction between a polyamine compound and a monocarboxylic acid, and combining the product of the first amidation reaction with an acid anhydride Carrying out the second amidation reaction, the polyamine compound contains at least one primary amino group and at least one secondary amino group or contains at least two primary amino groups, and the monocarboxylic acid contains at least one including 7-30 A hydrocarbon group of carbon atoms.

[0019] The polyamine compound can be vari...

specific Embodiment approach

[0040] According to a specific embodiment of the present invention, the amide compound is prepared in the following manner: at room temperature, mix the polyamine compound and the first unsaturated fatty acid, stir at a low speed of 80-100r / min for 20-30min, Then adjust the pH value of the obtained mixture to 7-9, then use an oil bath to heat the mixture to 220-230°C, and at the same time use a water separator to divide water, and maintain the temperature at 220-230°C for 3-5 hours, Then cool to room temperature to obtain "incomplete amide"; then at room temperature, mix "incomplete amide" with acid anhydride and / or polycarboxylic acid, and then use a water bath to heat the resulting mixture to 75-90°C, at 200- Stir at 500r / min for 6-10 hours.

[0041] The fatty acid compounds can be obtained commercially, or can be prepared according to various methods known to those skilled in the art. Preferably, the fatty acid compound is prepared according to the following method: at 150...

Embodiment 1

[0050] This example is used to illustrate the co-emulsifier provided by the present invention and its preparation method.

[0051] At room temperature of 25°C, diethylenetriamine and tall oil fatty acid were stirred and mixed for 30 minutes at a molar ratio of 1:1, and then heated to 220°C using an oil bath to react for 6 hours. Then the reaction product is cooled to room temperature, then slowly heated to 80°C, stirred while heating, adding maleic anhydride during the heating process, the amount of maleic anhydride makes the mol ratio of maleic anhydride and tall oil fatty acid to be 1:0.7, Afterwards, the temperature of the reaction system was maintained at 80° C. for 10 hours, and the co-emulsifier FR1 was obtained after cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com