Polyamide resin, and preparation method therefor and molded product thereof

A polyamide resin and post-polymerization technology, applied in the field of polyamide resin, can solve the problems such as the relative viscosity of polyoxamide resin cannot be improved, the viscosity of polyoxamide resin is decreased, and the melt retention stability is not improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

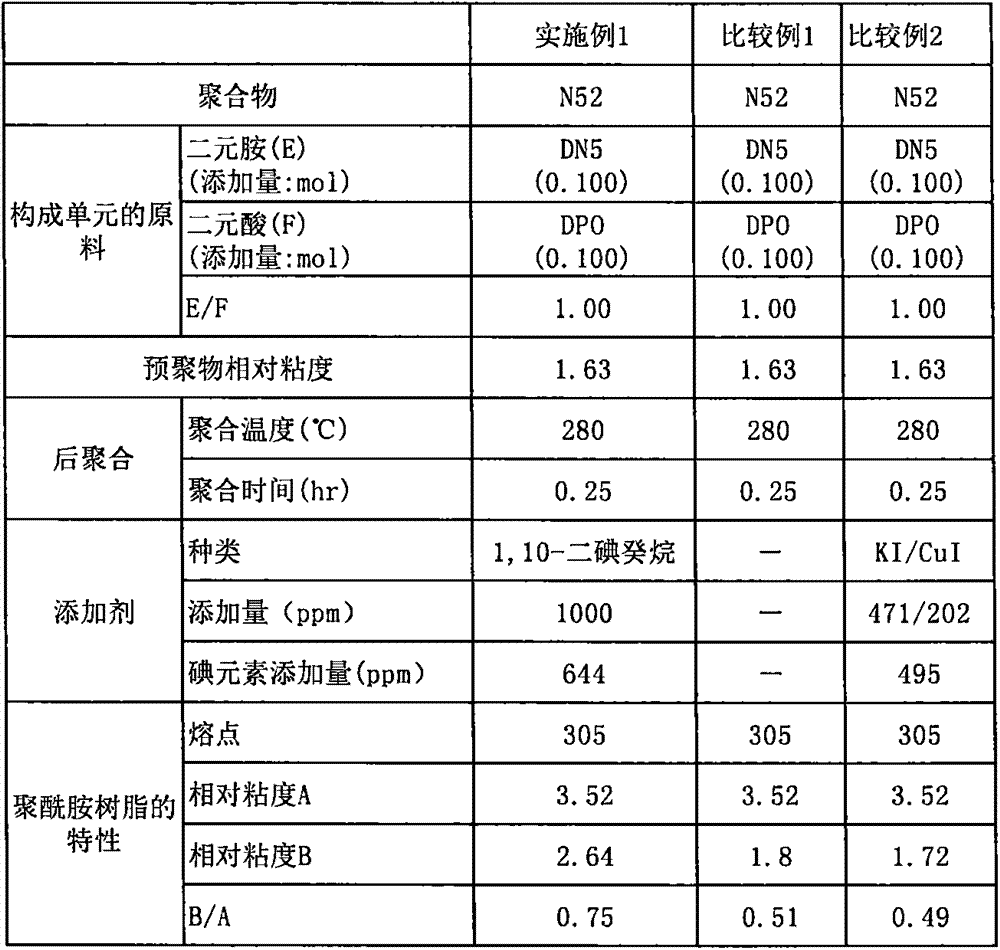

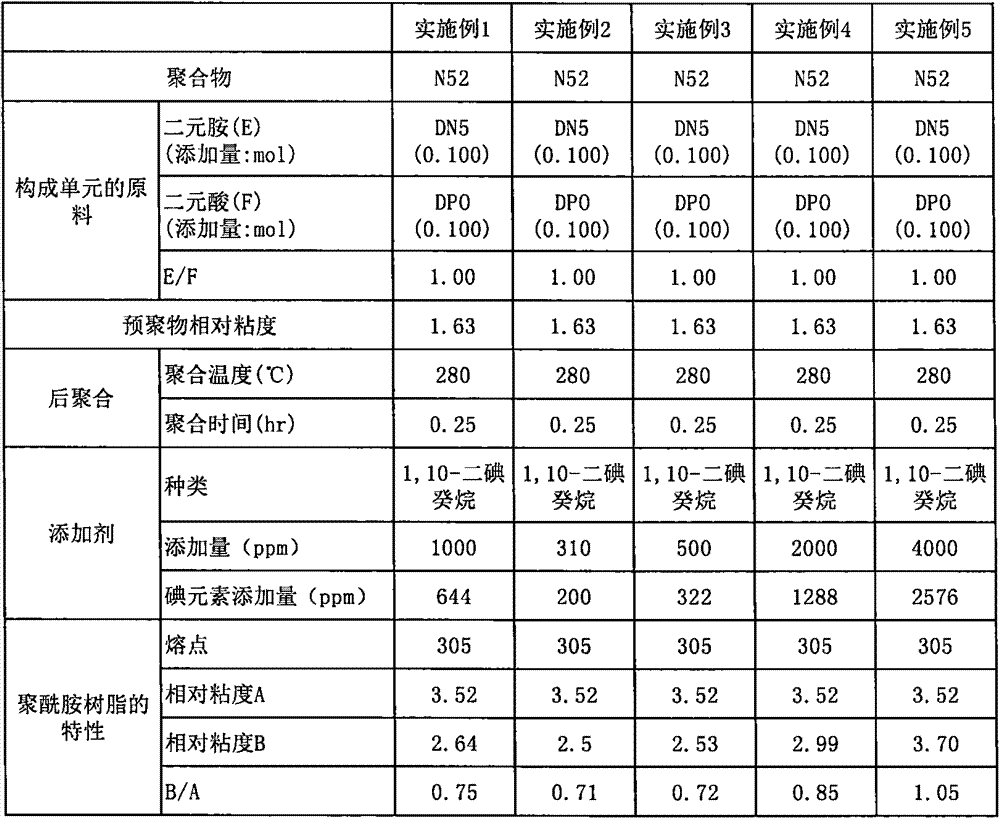

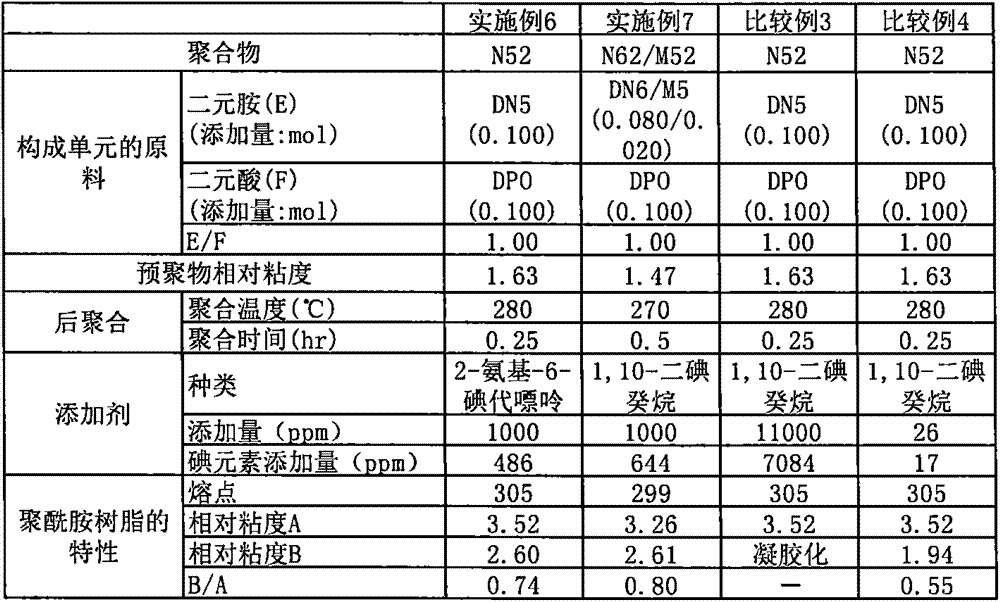

Embodiment 1

[0058] The three-necked flask (500ml) was first purged with nitrogen for 15 minutes, and then a certain nitrogen flow was maintained. Toluene (300 ml) and DPO (24.22 g, 0.100 mol) were added to the three-necked flask, followed by stirring and raising the temperature to 70°C. After DPO was completely dissolved in toluene at 70°C, DN5 (10.218 g, 0.100 mol) was added to the system, then the temperature was raised to 130°C, and the reaction was refluxed for 1 hour. This is followed by filtration and washing, followed by drying in a vacuum oven at 100°C for 12 hours. The relative viscosity of the obtained prepolymer was 1.63.

[0059] Feed 2.00 g of the obtained prepolymer into a glass test tube with a diameter of 19 mm, then replace it with nitrogen for 5 times, then reduce the pressure of the system to below 300 Pa, and then place it in a metal bath at 280 ° C for post-polymerization The reaction time is 0.25 hours. 2 g of the blend obtained by adding 1000 ppm 1,10-diiodod...

Embodiment 2

[0065] A polyamide resin was prepared in the same manner as in Example 1, except that the amount of 1,10 diiododecane added was 310 ppm.

Embodiment 3

[0067] A polyamide resin was prepared in the same manner as in Example 1, except that the amount of 1,10 diiododecane added was 500 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com