Polymer with surface active function and preparation method thereof

A technology of surface activity and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high injection pressure, slow development of medium and low permeability reservoirs, clogging of reservoir voids, etc., and achieve improved sweep Coefficient, increase the oil washing effect, strong effect of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

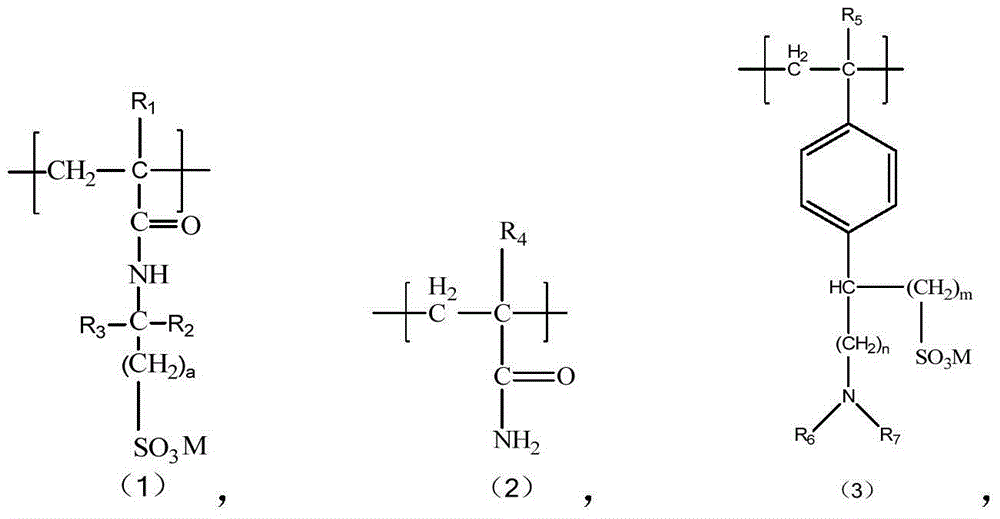

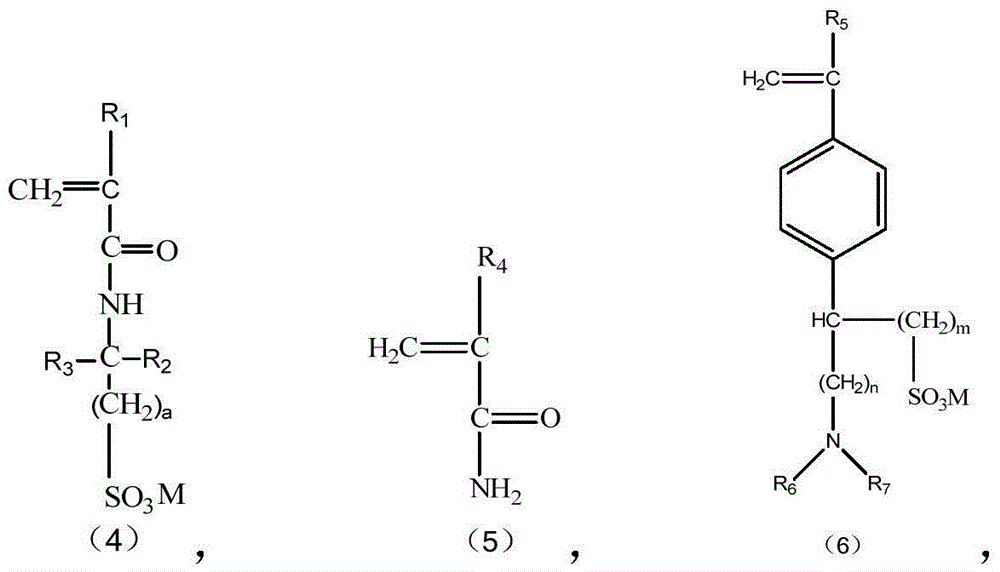

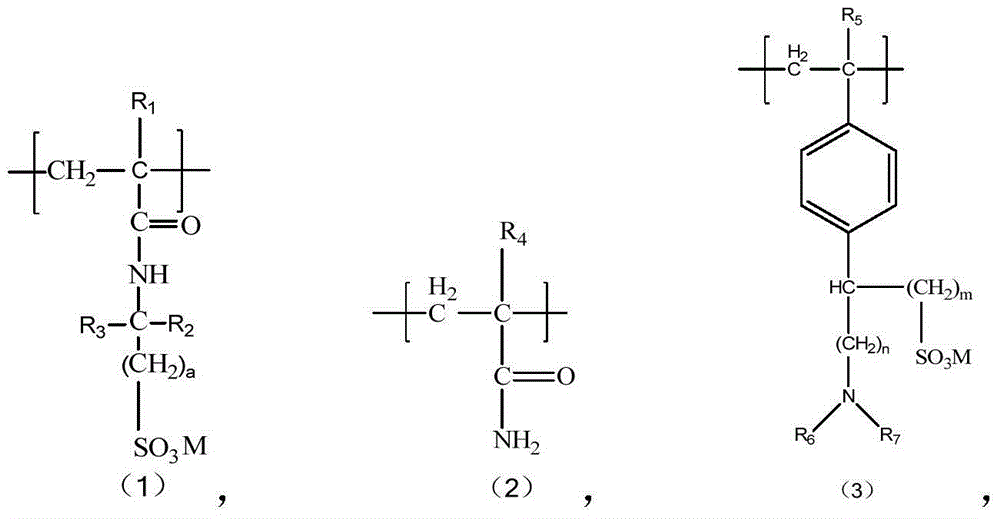

[0028] The present invention also provides a method for preparing a polymer with surface-active functions, the method comprising: under the conditions of a pH value of 6-10, under polymerization conditions, the monomer represented by formula (4), The monomer shown in formula (5), the monomer shown in formula (6), the solution that water, complexing agent and auxiliary agent form contact with initiator, with the total consumption mole number of monomer in the described polymkeric substance as Standard, the amount of the monomer shown in the formula (4) is 8-45 mol%, the amount of the monomer shown in the formula (5) is 50-91 mol%, and the amount of the monomer shown in the formula (6) The amount of the monomer is 0.001-5 mole %; the conditions of the polymerization reaction make the viscosity-average molecular weight of the polymer obtained after the polymerization reaction be 12 million-25 million; wherein, R 1 , R 2 , R 3 , R 4 and R 5 The same or different, each independ...

preparation example 1

[0064] This preparation example is used to illustrate the synthetic method of the monomer shown in the formula (6) in the embodiment 1:

Embodiment 1

[0067] In this embodiment, the method provided by the present invention is used to prepare the polymer 1-A with surface active function provided by the present invention, wherein the monomer described in formula (4) is 2-acrylamido-2-methylpropanesulfonic acid The monomer described in formula (5) is acrylamide; In the monomer described in formula (6) (hereinafter also referred to as functional monomer), m=1, n=2, R 6 and R 7 Both CH 3 , R 5 It is H, M is H, and its molecular weight is 283.

[0068] Specifically, this embodiment adopts the following method to carry out:

[0069] 1) Add acrylamide (166.2mmol), 2-acrylamido-2-methylpropanesulfonic acid (38.6mmol) and functional monomer (0.7mmol) into the polymerization reaction bottle (ie polymerization bottle), add deionized 50.0 g of water was dissolved to form an aqueous solution, and then sodium hydroxide was added to adjust the pH value to 8.0 to obtain a mixture solution;

[0070] 2) Add 1.0 g of 1% by weight EDTA-2Na ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com