Ozone gas floatation circular processing apparatus

A cyclic treatment and ozone flotation technology, applied in flotation water/sewage treatment, oxidized water/sewage treatment, filtration treatment, etc., can solve the problems of low ozone utilization, waste of ozone resources, ozone pollution, etc., to avoid ozone The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

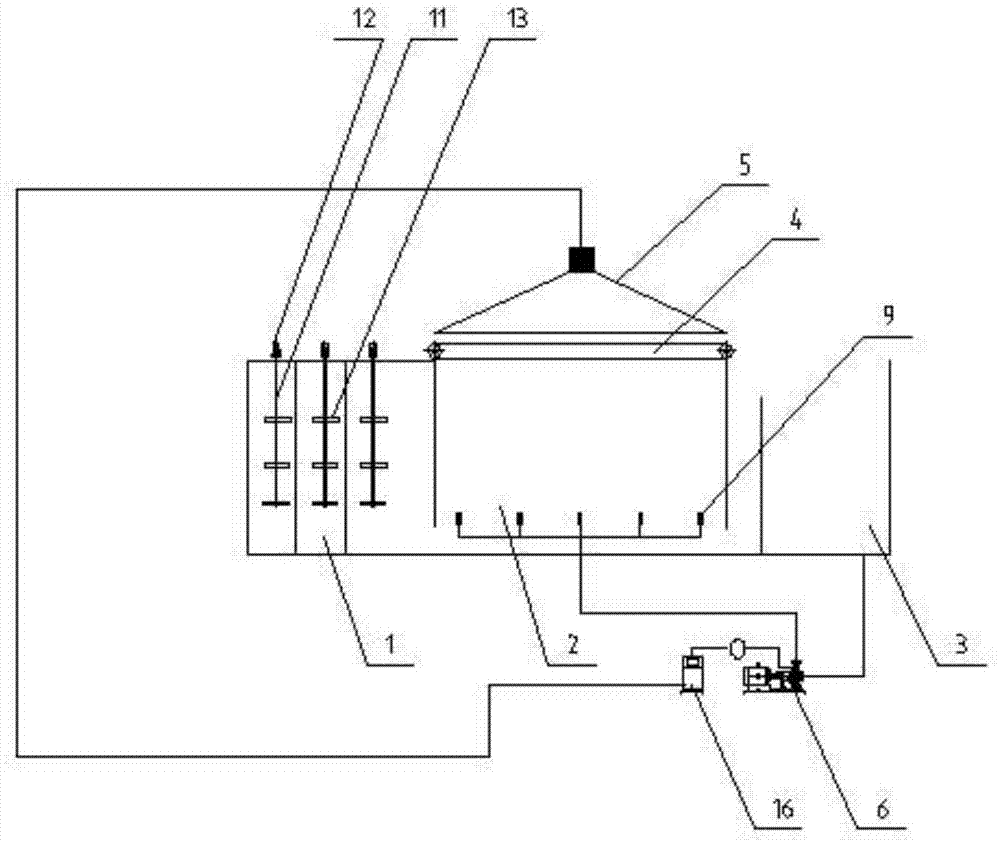

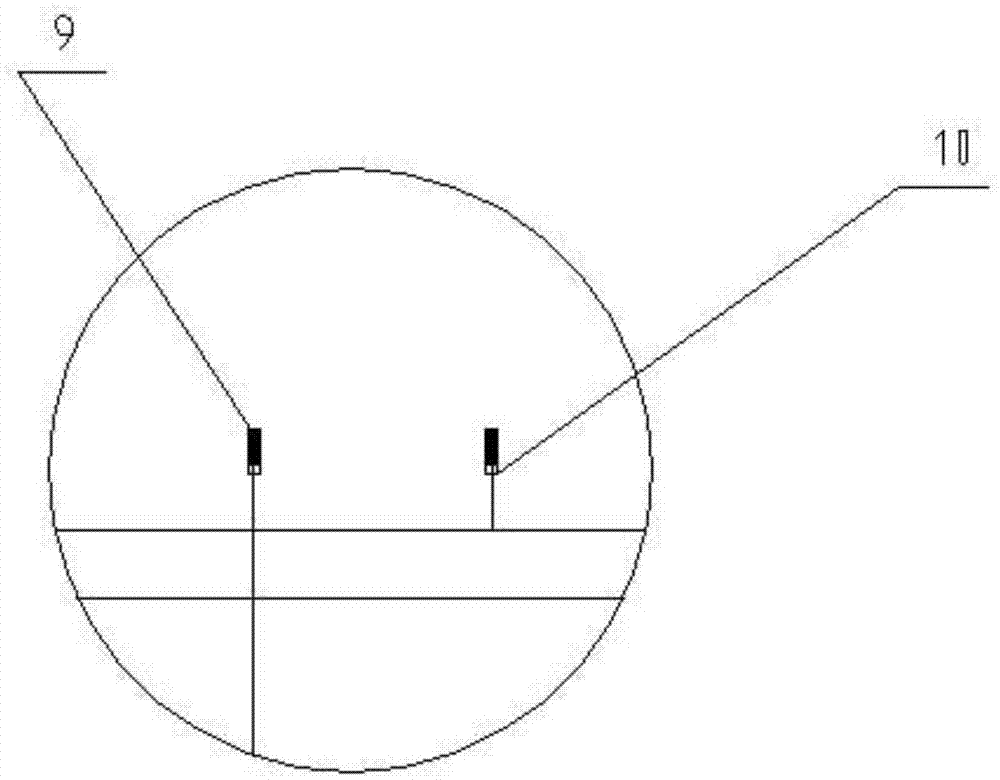

[0022] Such as figure 1 , image 3 , Figure 4 As shown, the ozone air flotation cycle treatment device includes a flocculation reaction tank 1, an air flotation tank 2 connected to the flocculation reaction tank 1 in turn, and a clear water tank 3; the top of the air flotation tank 2 is connected with a slag scraper 4 and an exhaust gas collection cover 5 in sequence; The collection cover 5 is connected to an ozone generator and a gas-liquid mixing pump 6 in turn through pipelines; the gas-liquid mixing pump 6 has a liquid inlet and a gas-liquid outlet, the liquid inlet is connected to the clear water pool 3, and the gas-liquid outlet is connected to the air flotation pool 2; the air flotation pool The bottom of 2 is provided with a plurality of horizontal tubes 7 and a plurality of vertical tubes 8; a plurality of horizontal tubes 7 are arranged in sequence, and at least one vertical tube 8 is communicated between adjacent horizontal tubes 7; any horizontal tube 7 or any ve...

Embodiment 2

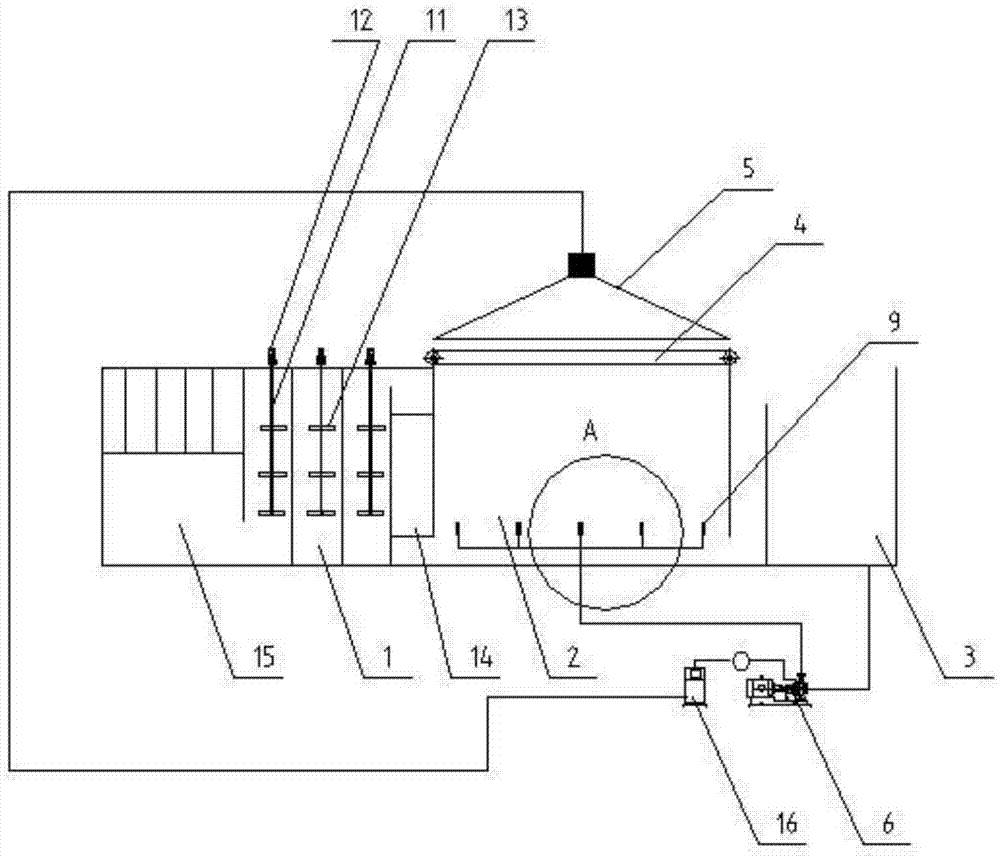

[0025] Figure 2-4 As shown, the difference between this embodiment and Example 1 is that the flocculation reaction pool 1 is connected with a grid pool 15, and the grid pool 15 is connected with the sewage pool to be treated; an adsorption pool is connected between the flocculation reaction pool 1 and the air flotation pool 2 14. The adsorption pool 14 is provided with any one or more of activated carbon, montmorillonite, and medical stone; the adsorption pool 14 may also be provided with other devices with adsorption functions.

[0026] Figure 2-4 As shown, when the embodiment 1 and the embodiment 2 are in use, the sewage enters the grid pool 15 from the sewage pool to be treated and enters the flocculation reaction pool 1 after preliminary filtration, and is flocculated by the flocculant dosing machine and the coagulant dosing machine. After adding medicine in the reaction tank 1 to make the suspended solids and small particles in the sewage settle quickly, it enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com