Preparation method of electronegative monolayer graphene

A single-layer graphene, electronegative technology, which is applied in the field of preparation of negatively charged single-layer graphene, can solve the problems of high toxicity of organic solvents, poor biocompatibility, high price, etc. The method is simple, low-cost, and easy to promote Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

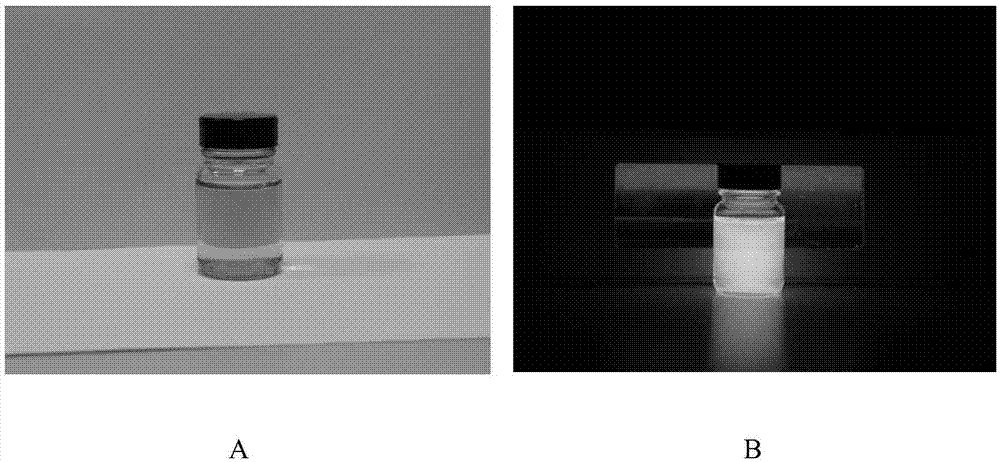

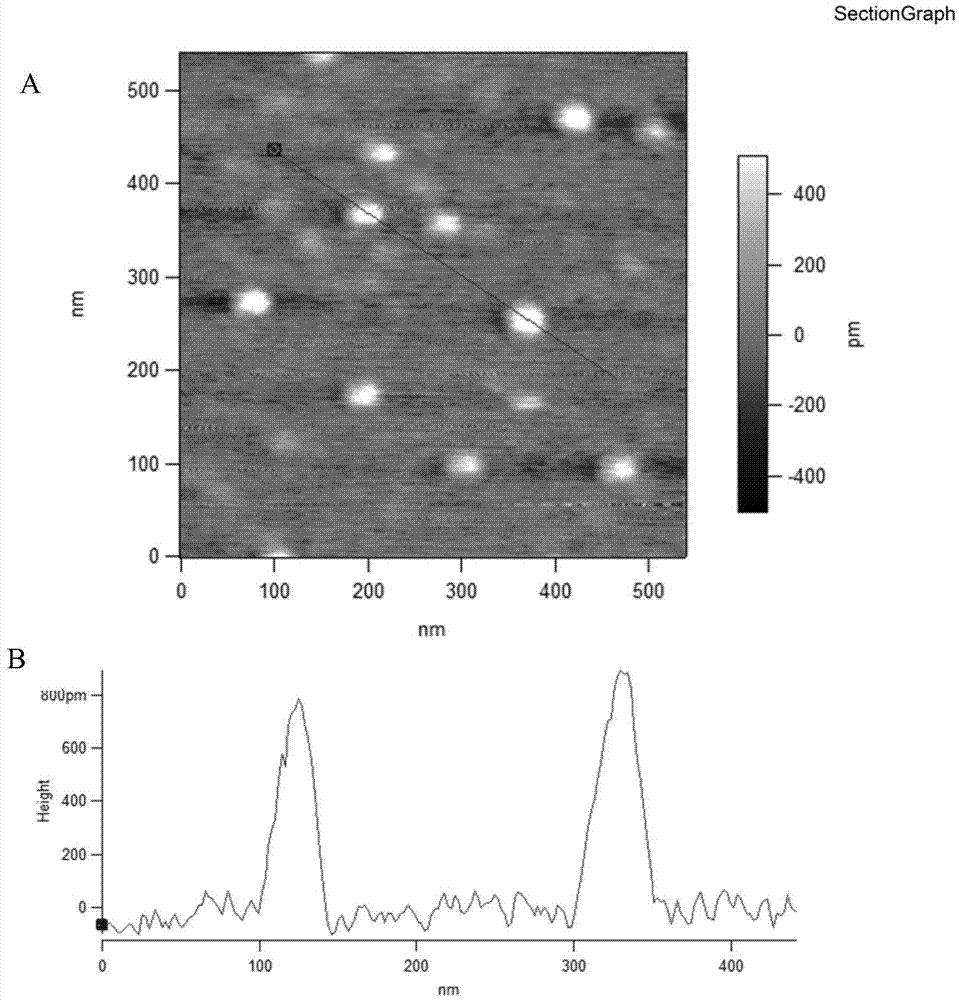

[0035] 1. Preparation of low carbon to oxygen ratio graphene quantum dot solution

[0036] Using 1,3,6-trinitropyrene as a carbon source, 1,3,6-trinitropyrene was synthesized by hydrothermal method after ultrasonication in sodium hydroxide solution. Among them, the concentration of 1,3,6-trinitropyrene is 5.0 mg / mL, the concentration of sodium hydroxide solution is 0.3 mol / L, the ultrasonic time is 4 hours, the hydrothermal synthesis conditions are 200 ° C, 4 hours, the solution volume Account for 40% of the volume of the hydrothermal kettle. The graphene quantum dot solution is the solution obtained by hydrothermal synthesis. First, it is fully dialyzed with a dialysis bag with a molecular weight cut-off of 1000 Da, and then the solution in the dialysis bag is collected. Elemental analysis and characterization showed that the carbon and oxygen atomic content ratio was 1.5:1.

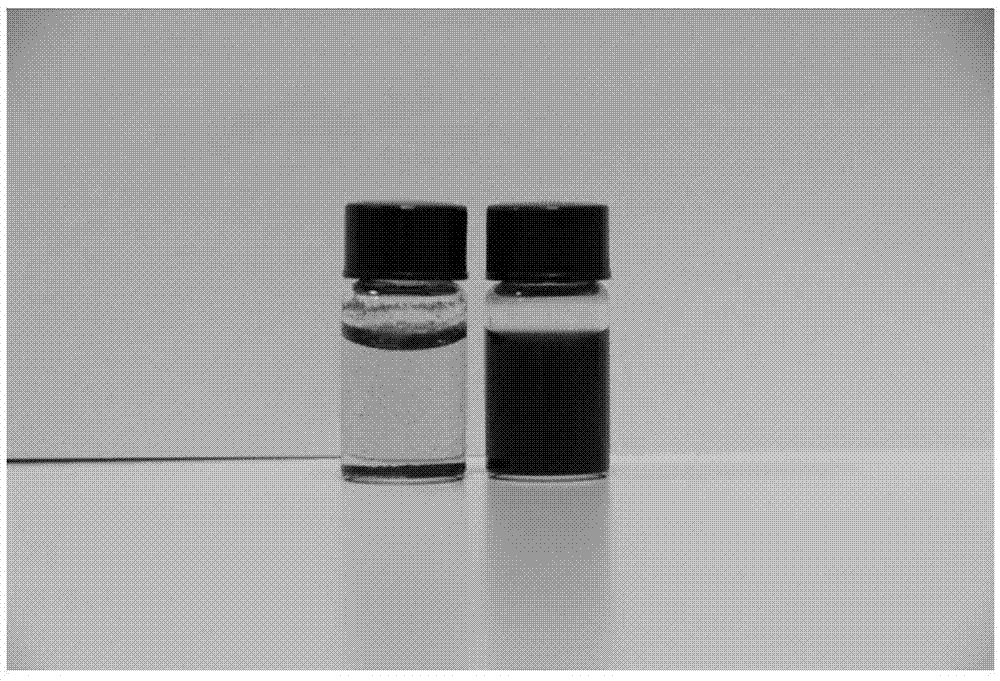

[0037] 2. Preparation of single-layer graphene

[0038] Graphite with a particle size of 80 mesh ...

Embodiment 2

[0052] 1. Preparation of low carbon to oxygen ratio graphene quantum dot solution

[0053] Using 1,3,6-trinitropyrene as a carbon source, 1,3,6-trinitropyrene was synthesized by hydrothermal method after ultrasonication in sodium hydroxide solution. Among them, the concentration of 1,3,6-trinitropyrene is 1.0 mg / mL, the concentration of sodium hydroxide solution is 0.5 mol / L, the ultrasonic time is 3 hours, the hydrothermal synthesis conditions are 180°C and 8 hours, the solution volume Account for 30% of the volume of the hydrothermal kettle. The graphene quantum dot solution is obtained by hydrothermal synthesis, after fully dialysis with a dialysis bag with a molecular weight cut-off of 1000Da, the solution in the dialysis bag is collected, and then the gained solution is placed in a 3500Da dialysis bag for sufficient dialysis, and then freeze-dried . Elemental analysis and characterization show that the ratio of carbon and oxygen atoms is 1.2:1.

[0054] 2. Preparation ...

Embodiment 3

[0061] 1. Preparation of low carbon to oxygen ratio graphene quantum dot solution

[0062] Using 1,3,6-trinitropyrene as a carbon source, 1,3,6-trinitropyrene was synthesized by hydrothermal method after ultrasonication in sodium hydroxide solution. Among them, the concentration of 1,3,6-trinitropyrene is 3.0 mg / mL, the concentration of sodium hydroxide solution is 1.0 mol / L, the ultrasonic time is 4 hours, the hydrothermal synthesis conditions are 190°C and 6 hours, the solution volume Account for 25% of the volume of the hydrothermal kettle. The graphene quantum dot solution is obtained by hydrothermal synthesis, after fully dialysis with a dialysis bag with a molecular weight cut-off of 1000Da, the solution in the dialysis bag is collected, and then the gained solution is placed in a 3500Da dialysis bag for sufficient dialysis, and then freeze-dried . Elemental analysis and characterization showed that the carbon and oxygen atomic content ratio was 1.8:1.

[0063] 2. Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com