Sarcandra glabra facial mask base fabric, preparation method and preparation system

A grass coral fiber and coral technology, which is applied in the field of mask base fabric manufacturing, can solve the problems of lack of functionality of mask base fabric, incomplete degradation, low production speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

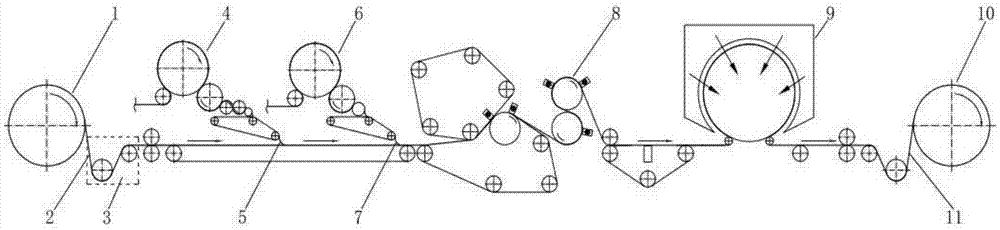

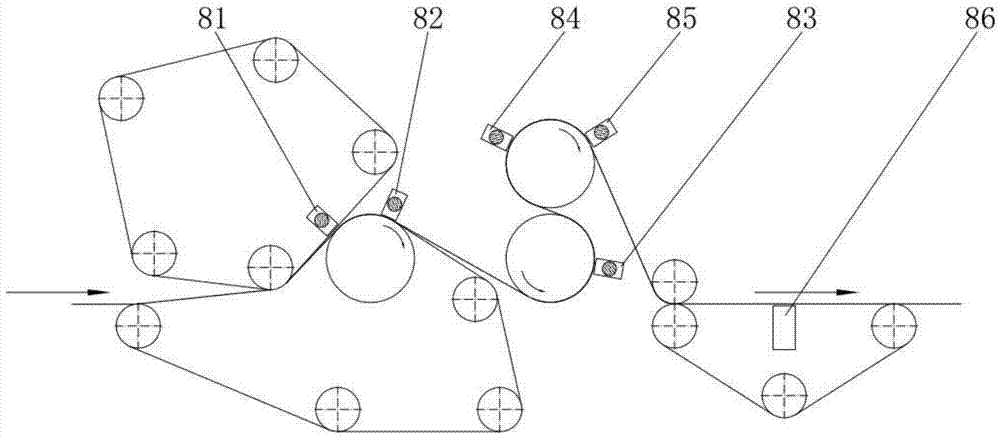

[0036] The preparation system of grass coral facial mask base cloth, such as figure 2 As shown, it includes a protective layer unwinder 1 connected in sequence, a carding machine 4 with agglomeration rollers, a carding machine 6 that directly strips the doffer into a web, a spunlace system 8, a dryer 9, and a winder 10. The lactic acid spunbonded nonwoven fabric is unrolled by the protective layer unwinder, adjusted by the tension adjustment structure 3, and then laminated with the liquid storage layer fiber web formed by the random carding of the carding machine with coagulation rollers to form a two-layer laminate. The two-layer laminate and The functional layer fiber web formed by the carding machine that is directly peeled off by the doffer is superimposed to form a three-layer laminate. The three-layer laminate is fed into the spunlace system for spunlace entanglement and compounding to obtain the wet grass coral mask base fabric. The wet state The grass coral mask base ...

Embodiment 1

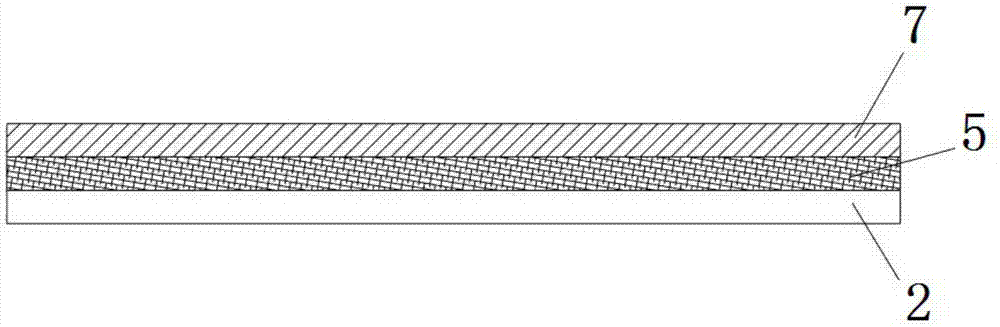

[0046] A grass coral facial mask base cloth, which is a three-layer fiber web of functional layer web 7, liquid storage layer web 5 and protective layer web 2 from top to bottom, and the functional layer web 7 is made of 100% grass Coral fiber is made of, and its surface density is 12 grams / square meter; Described liquid storage layer web 5 is made of 100% viscose fiber, and its surface density is 11 grams / square meter; Described protective layer fiber web 2 is vertical and horizontal The polylactic acid spunbonded nonwoven fabric with a strength ratio of 1.2:1 has an areal density of 12 grams per square meter. The grass coral fiber fiber of the functional layer web 7 has a length of 45 mm and a linear density of 1.56 dtex; the viscose fiber of the liquid storage layer web 5 has a length of 45 mm and a linear density of 1.56 dtex; The fiber fineness of the protective layer web 2 is 1.1 decitex. The preparation steps refer to the above, and the functional layer web 7, the liqu...

Embodiment 2

[0048]A kind of grass coral facial mask base cloth, it is successively three layers of fiber webs of functional layer fiber web 7, liquid storage layer fiber web 5 and protective layer fiber web 2 from top to bottom, and described function layer fiber web 7 is added by weight ratio It is composed of 85% grass coral fiber and 15% bamboo pulp fiber, and its surface density is 15 grams per square meter; the liquid storage layer fiber web 5 is made of 100% viscose fiber, and its surface density is 15 grams per square meter m; the protective layer fiber web 2 is a polylactic acid spunbonded nonwoven fabric with a vertical and horizontal strength ratio of 1.1:1, and its surface density is 15 grams per square meter. The grass coral fiber fiber of the functional layer web 7 has a length of 42 mm and a linear density of 1.65 dtex; the viscose fiber of the liquid storage layer web 5 has a length of 42 mm and a linear density of 1.65 dtex; The fiber fineness of the protective layer web 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com