Waste organic glass cutting and crushing device

A plexiglass and crushing device technology, which is applied in the direction of mechanical material recovery, recycling technology, grain processing, etc., can solve the problems of affecting production, long residence time, and low crushing efficiency, so as to reduce crushing costs, improve work efficiency, and achieve high efficiency. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

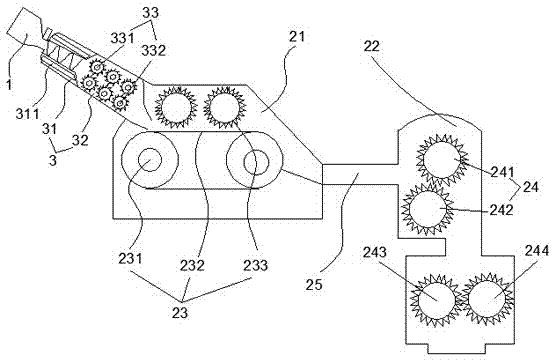

[0018] A cutting and crushing device for waste and old plexiglass, as attached figure 1 As shown, including feed structure 1 and crushing structure. Its crushing structure includes a closed primary crushing chamber 21 and a secondary crushing chamber 22. The two crushing chambers are connected by a flat neck 25. The primary crushing chamber 21 is provided with a primary crushing component 23, and the secondary crushing chamber 22 is provided with a There is a secondary crushing part 24, which crushes the plexiglass sequentially; the position of the primary crushing chamber 21 is higher than that of the secondary crushing chamber 22, which facilitates the transportation of materials. The primary crushing part 23 includes two driving rollers 231 driven by a driving motor, a conveyor belt 232 arranged on the outer rings of the two driving rollers 231, and two cutting rollers 233, and the cutting rollers 233 are installed in the primary crushing chamber 21 on the inner wall, loca...

Embodiment 2

[0020] A cutting and crushing device for waste organic glass, comprising a feeding structure 1, an extruding structure 3 and a crushing structure arranged in sequence along the transport direction of materials. The extruding structure 3 includes a mixing chamber 31, an extruding chamber 32 communicating with the mixing chamber 31, and an extruding part 33 arranged in the extruding chamber 32 to extrude relatively fluffy materials in the feeding structure to increase crushing time. The density of the material improves the crushing effect; the extrusion part 33 includes an upper extrusion roller 331 and a lower extrusion roller 332 relative to the upper extrusion roller 331, and the mixing chamber 31 is provided with a heating tube 311 to give the plexiglass a certain temperature. Aids in breaking. Its crushing structure includes a closed primary crushing chamber 21 and a secondary crushing chamber 22. The two crushing chambers are connected by a flat neck 25. The primary crushi...

Embodiment 3

[0022] A cutting and crushing device for waste organic glass, comprising a feeding structure 1, an extruding structure 3 and a crushing structure arranged in sequence along the transport direction of materials. The extruding structure 3 includes a mixing chamber 31, an extruding chamber 32 communicating with the mixing chamber 31, and an extruding part 33 arranged in the extruding chamber 32 to extrude relatively fluffy materials in the feeding structure to increase crushing time. The density of the material improves the crushing effect; the extruding part 33 includes an upper extruding roller 331 and a lower extruding roller 332 opposite to the upper extruding roller 331, and the mixing chamber 31 includes a conveying cavity for conveying plexiglass and is surrounded by a conveying cavity The outer heating cavity is provided with a heating pipe 311 in the heating cavity, and a screw push rod driven by a motor is provided in the delivery cavity. Give the plexiglass a certain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com