Glass grinding machine

A grinding machine and glass technology, which is applied to the parts of grinding machine tools, grinding machines, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of insufficient functions, poor grinding effect, inconvenient use, etc., and improve the practical effect , improve work efficiency, and facilitate the suction of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

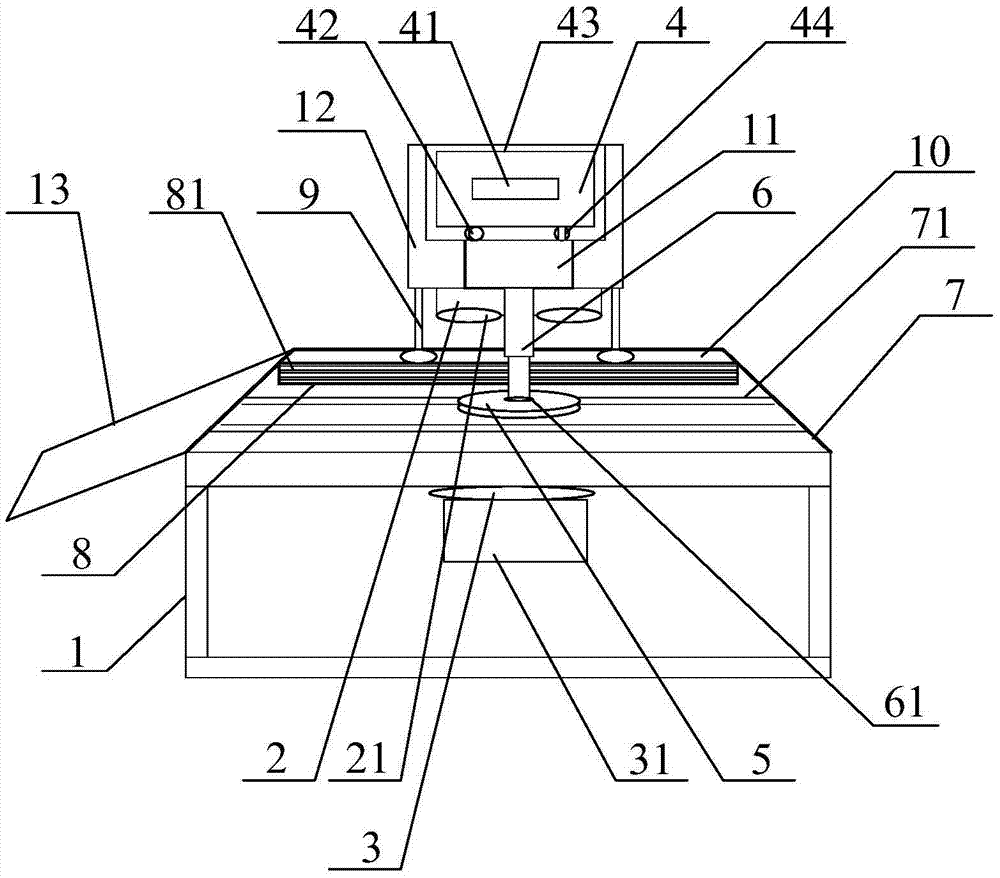

[0018] Such as figure 1 As shown: the present invention provides a glass grinding machine, including a bracket 1, a bucket 2, a fan 3, a PLC control structure 4, a grinding turntable 5, a telescopic tube 6, a workbench 7, a positioning block 8, a moving rod 9, and a chute 10 , motor 11, protective box 12 and swash plate 13, described support 1 is arranged in the middle of protective box 12 and chute 10; Described bucket 2 is arranged on both sides of telescopic tube 6; Described fan 3 is arranged on The bottom of the workbench 7; the PLC control structure 4 is set on the top of the motor 11; the grinding turntable 5 is set on the bottom of the telescopic tube 6; the positioning block 8 is set on the front part of the chute 10; Described swash plate 13 is arranged on the left side of workbench 7; Described PLC control structure 4 comprises PLC controller 41, power switch 42, touch screen 43 and adjusting knob 44, and described PLC controller 41 is arranged on touch screen 43 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com