Intelligent machining system for aluminum alloy body structural members of new energy automobiles

A new energy vehicle and machining system technology, applied in the field of intelligent machining systems, can solve the problems of inability to process internal measuring holes, inability to process machining centers, and large spindles of five-axis machine tools, achieving exquisite structure, high machining accuracy, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

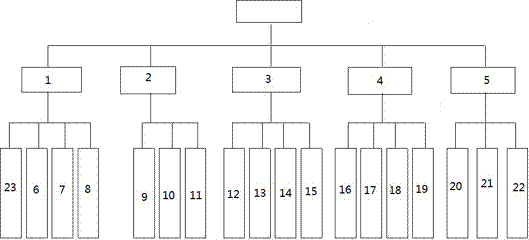

[0019] like figure 1 It shows the specific implementation of the present invention: an intelligent machining system for aluminum alloy body structure parts of new energy automobiles: it includes a control system, and the control system includes an intelligent system 1, a cutting minimal quantity lubrication system 2, a tool system 3, a high Precision CNC turntable system 4 and precision intelligent fixture 5. The intelligent system 1 includes a six-axis joint robot 23, a height electric spindle 6, an angle head orienter 7 and a hydraulic broach mechanism 8. The cutting minimal lubrication system 2 includes mist Converter 9, switching valve 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com