Multi-cutter-location numerical control lathe

A CNC lathe and multi-tool position technology, applied in the field of machining, can solve problems such as unreasonable cooling mechanism settings, potential safety hazards, equipment failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

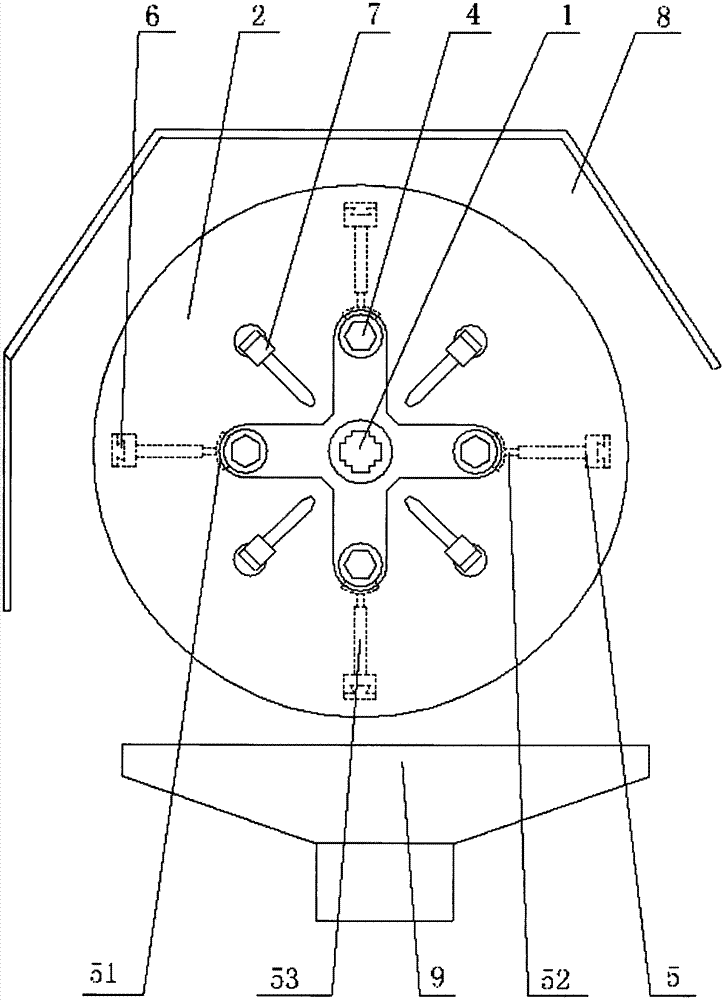

[0018] Refer to attached figure 1 As shown, the multi-tool station CNC lathe of the present invention includes a workpiece clamping mechanism and a tool clamping mechanism, the workpiece clamping mechanism is provided with a feed drive mechanism, the tool clamping mechanism is provided with a displacement drive mechanism, and the tool clamping mechanism includes a positioning Axis 1, positioning shaft 1 is equipped with a cutter disc 2, the cutter disc 2 has at least two tool movable grooves 3, and the cutter 4 is arranged in the tool movable groove along the axial direction of the cutter disc, and the cutter 2 includes at least two sets of cutter head shapes Different turning tools, wherein at least one group of turning tools has two or more cutter heads; the positioning shaft 1 is located at the center of the tool disc 2, and one end of the tool m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com