Liquid cooling system for server

A server and blade server technology, applied in the direction of using liquid cooling for modification, cooling/ventilation/heating transformation, etc., can solve the problems of inability to fill and empty, difficult to fill or empty, complicated and cumbersome process, etc., and achieve convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

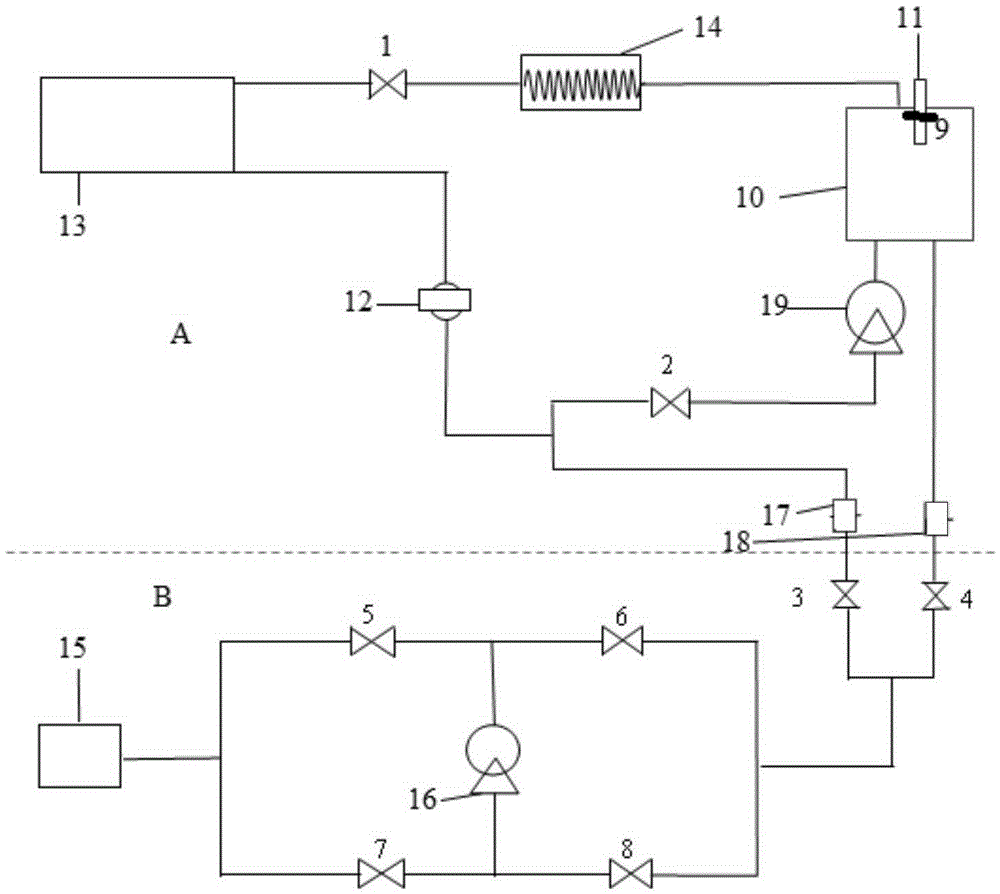

[0022] figure 1 It is a schematic structural diagram of an embodiment of the liquid cooling system for servers of the present invention. Such as figure 1 As shown, the liquid cooling system for servers in this embodiment may include: a refrigeration device A and a liquid-filling and liquid-receiving device B, wherein the liquid-filling and liquid-receiving device B is detachably connected to the refrigeration device A to supply cooling equipment to the refrigeration device A. The refrigerant is drawn in or discharged from the refrigeration unit A.

[0023] Specifically, the upper part is a schematic diagram of the structure of the cooling device A. When the server is running, the heat generated by the CPU and various electronic components causes the refrigerant to boil and become refrigerant vapor. The refrigerant vapor and hot fluid generated by each server flow out through the top of the server, gather together, and become cold fluid again after condensation, and the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com