BP neural network and MBFO algorithm-based aluminum electrolysis energy conservation and emission reduction control method

A BP neural network, energy saving and emission reduction technology, applied in the direction of neural learning method, biological neural network model, etc., can solve the problems of high energy consumption, environmental pollution, low efficiency, etc., to achieve the effect of improving current efficiency and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

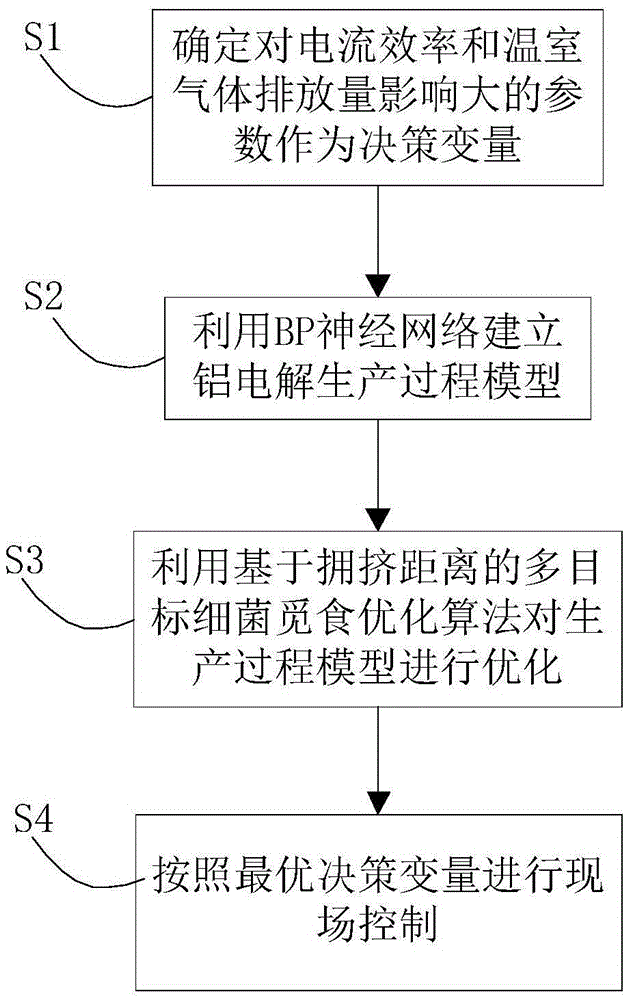

[0047] Such as figure 1 As shown, a control method for energy saving and emission reduction of aluminum electrolysis based on BP neural network and MBFO algorithm includes the following steps:

[0048] S1: Select control parameters that have an impact on current efficiency and greenhouse gas emissions to form a decision variable X=[x 1 ,x 2 ,...,x M ], M is the number of selected parameters;

[0049] The implementation is to count the original variables that have an impact on the current efficiency and greenhouse gas emissions in the aluminum electrolysis production process, and determine the parameters that have a large impact on the current efficiency and greenhouse gas emissions as the decision variable X;

[0050] Through the statistics of the measured parameters in the actual industrial production process, the variables that have the greatest impact on current efficiency and greenhouse gas emissions are: series current x 1 , times of feeding x 2 , Molecular ratio x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com