Mobile terminal and pressure sensing device thereof

A technology of an induction device and a mobile terminal, which is applied in the fields of instruments, electrical digital data processing, and data processing input/output process, etc. The effect of reducing assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

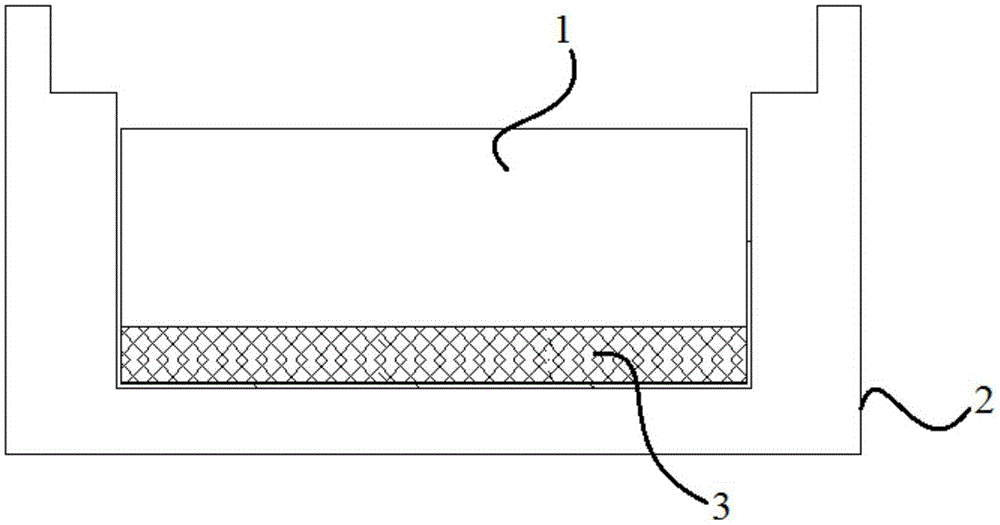

[0021] Such as figure 1 As shown, this embodiment provides a pressure sensing device for a mobile terminal, the mobile terminal includes a display module 1 and a middle frame 2, the pressure sensing device includes a pressure sensor 3 disposed at the bottom of the middle frame 2, The pressure sensor 3 is pasted on the lower surface of the display module 1 .

[0022] In this embodiment, by affixing the pressure sensor on the lower surface of the display module, it avoids stacking the entire pressure sensing layer on the middle frame of the whole machine, and does not require the middle frame to be made of metal material, nor does it need to be grounded, thereby reducing The requirements on the middle frame of the whole machine are lowered, and the assembly requirements on the whole machine during installation are reduced, so that the pressure sensing device and the mobile terminal of the present invention meet the conditions for mass production.

Embodiment 2

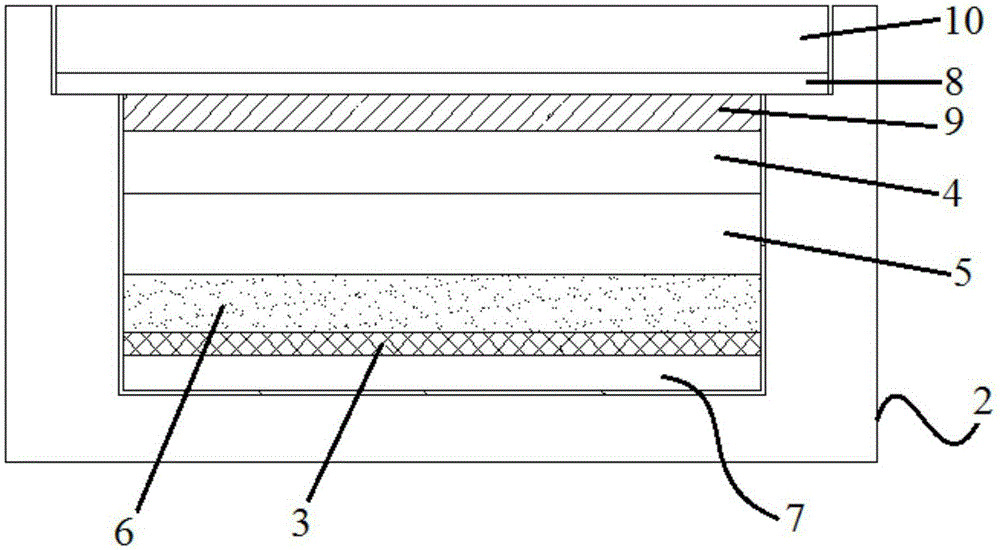

[0024] Such as figure 2 As shown, the difference between the pressure sensing device of the mobile terminal of this embodiment and Embodiment 1 is that: in this embodiment, the display module includes an LCM, and the LCM includes an LCD 4 and a backlight module (i.e., a BackLight module) 5 , the pressure sensor 3 is specifically pasted on the lower surface of the backlight module 5 through the foam glue 6 .

[0025] The bottom of the middle frame 2 is also provided with a flexible insulating substrate 7 on which the pressure sensor 3 is disposed. Preferably, the flexible insulating substrate is a PI substrate.

[0026] A touch sensor 8 is pasted on the upper surface of the LCD4, and the touch sensor 8 is specifically pasted on the upper surface of the LCD4 through a transparent optical glue 9. Glass cover 10.

[0027] In this embodiment, the Vcom layer (reference voltage layer) of the LCD can be selected as the reference terminal of the self-capacitance. When the LCD is pre...

Embodiment 3

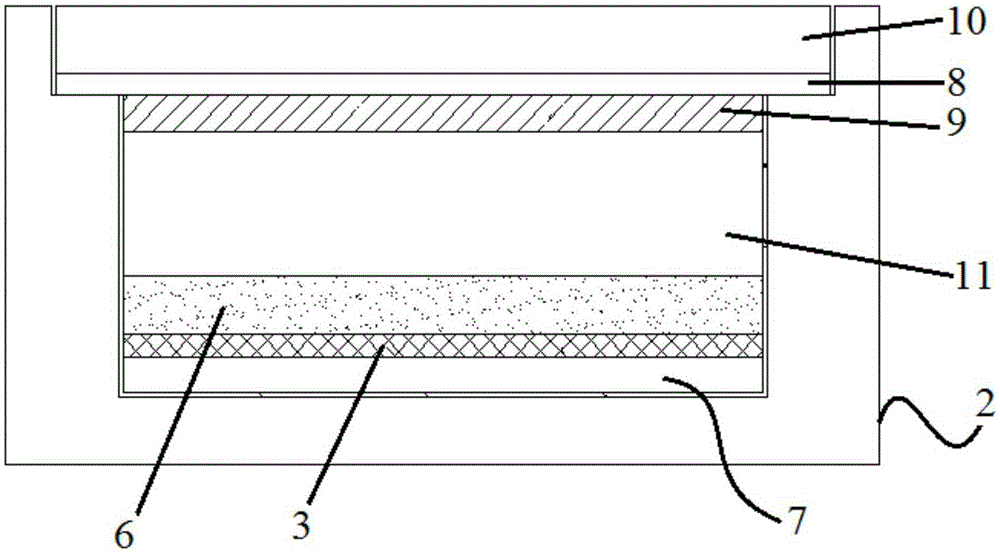

[0030] Such as image 3 As shown, the difference between the pressure sensing device of the mobile terminal in this embodiment and Embodiment 2 is that in this embodiment, the display module includes an AMOLED display screen 11 instead of an LCM, and the pressure sensor 3 Specifically, the foam glue 6 is pasted on the lower surface of the AMOLED display screen.

[0031] The bottom of the middle frame 2 is also provided with a flexible insulating substrate 7 on which the pressure sensor 3 is disposed. Preferably, the flexible insulating substrate is a PI substrate.

[0032] A touch sensor 8 is pasted on the upper surface of the AMOLED display screen 11, and the touch sensor 8 is specifically pasted on the upper surface of the AMOLED display screen 11 through a transparent optical glue 9. The upper surface is also provided with a glass cover 10.

[0033] In this embodiment, the cathode of the AMOLED display screen can be selected as the reference terminal of the self-capacitan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com