Matrix automatic impedance tester and testing method

An automatic impedance and tester technology, applied in the direction of measuring resistance/reactance/impedance, instruments, measuring devices, etc., can solve the problem of time-consuming and laborious manual inspection, and achieve the effect of improving test efficiency, easy to use, and easy to build.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

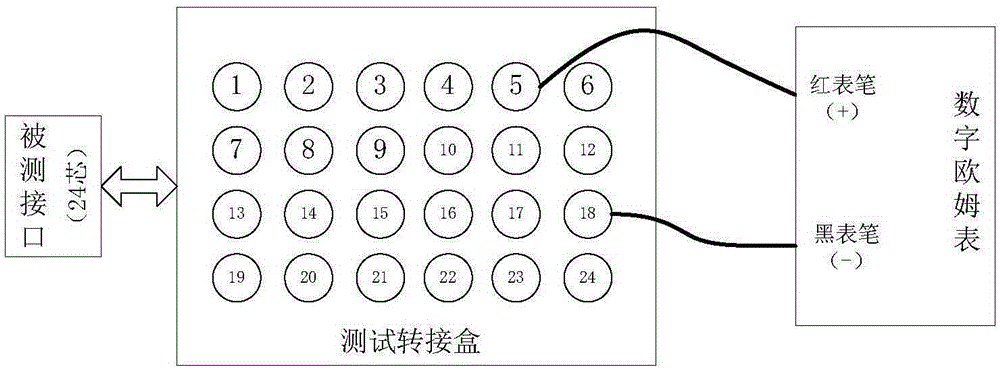

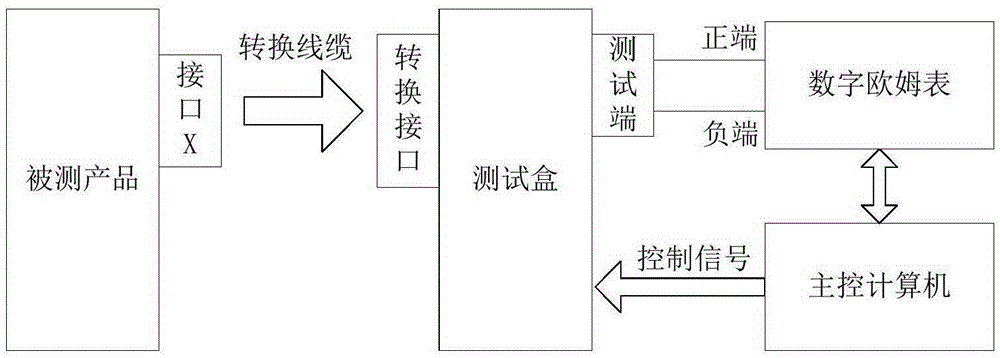

[0026] see figure 2 , The matrix automatic impedance tester provided by the present invention mainly includes a test box, a digital ohmmeter and a main control computer.

[0027] The interface conversion cable is used to connect the tested interface of the product and the program-controlled array test box, so as to realize the conversion between the product-specific interface and the general-purpose interface of the program-controlled array test box. The test of the tested contact is transferred to the test box, and each contact in the interface X corresponds to each measuring point in the test box.

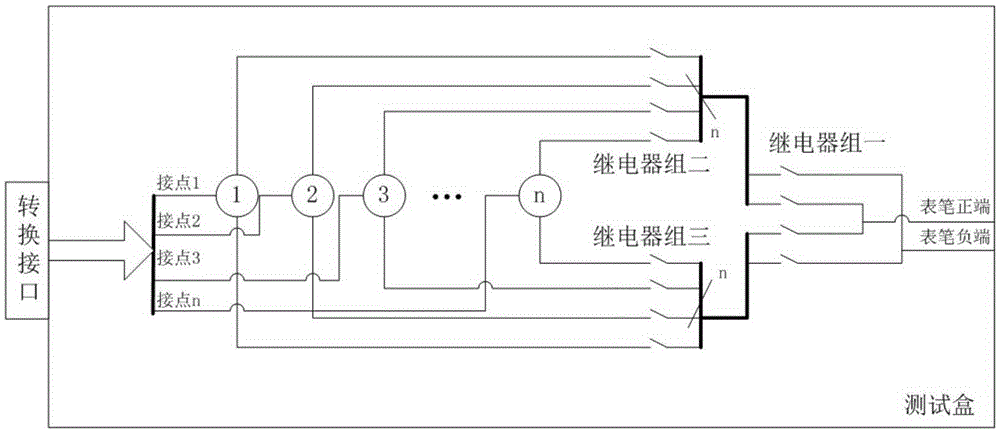

[0028] The main control computer is equipped with a measurement control module and two digital interface cards to work together to complete the required measurement work. The two digital interface cards respectively control the positive and negative input ports of the digital ohmmeter. Each output port of the interface card is connected to the relay drive terminal on the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com