Drinking water pipe sealing expansion joint and sealing expansion drinking water pipe

A technology for expansion joints and drinking water pipes, which is applied in the directions of pipes/pipe joints/pipe fittings, pipe connection arrangements, hose connection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

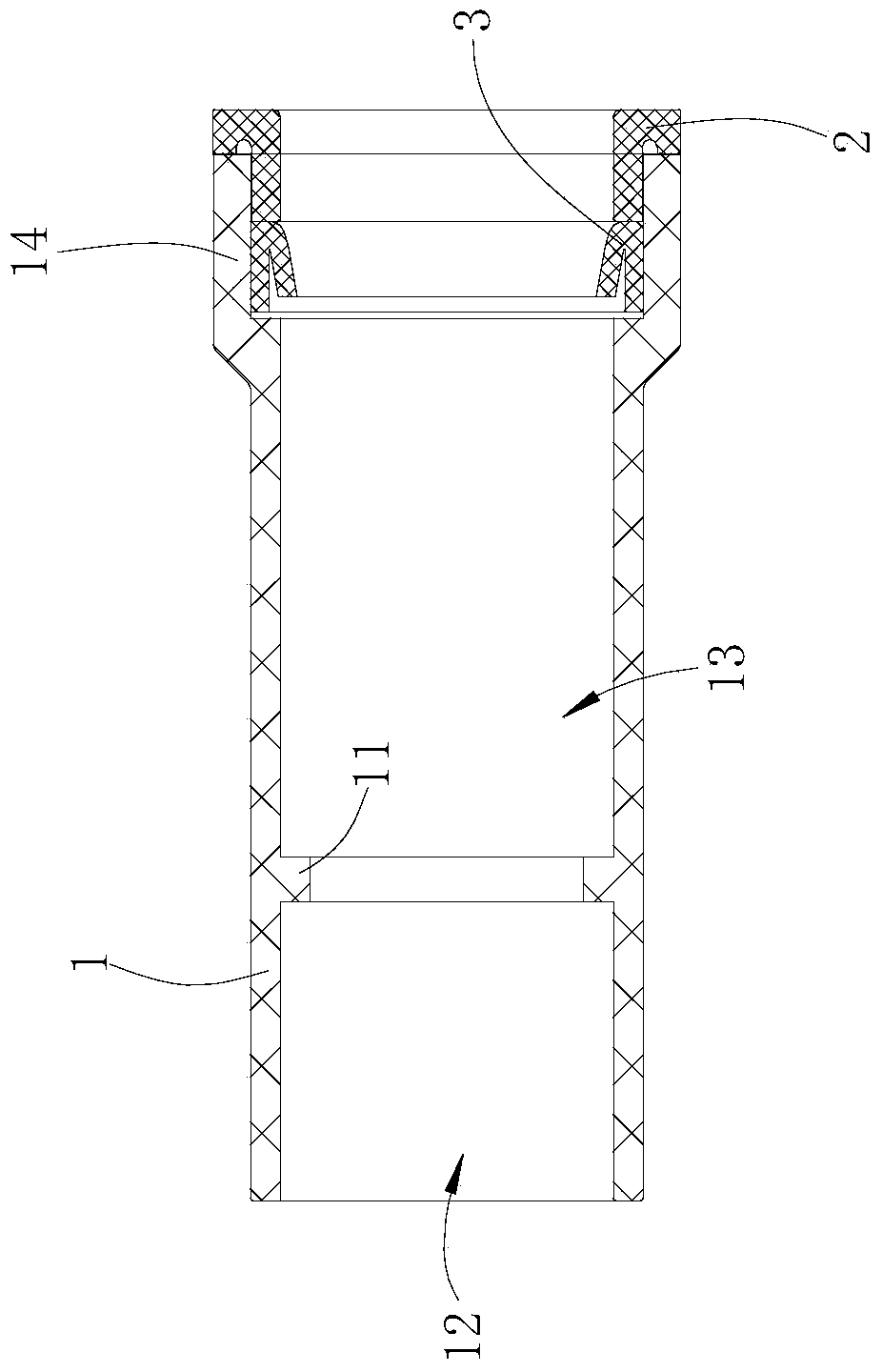

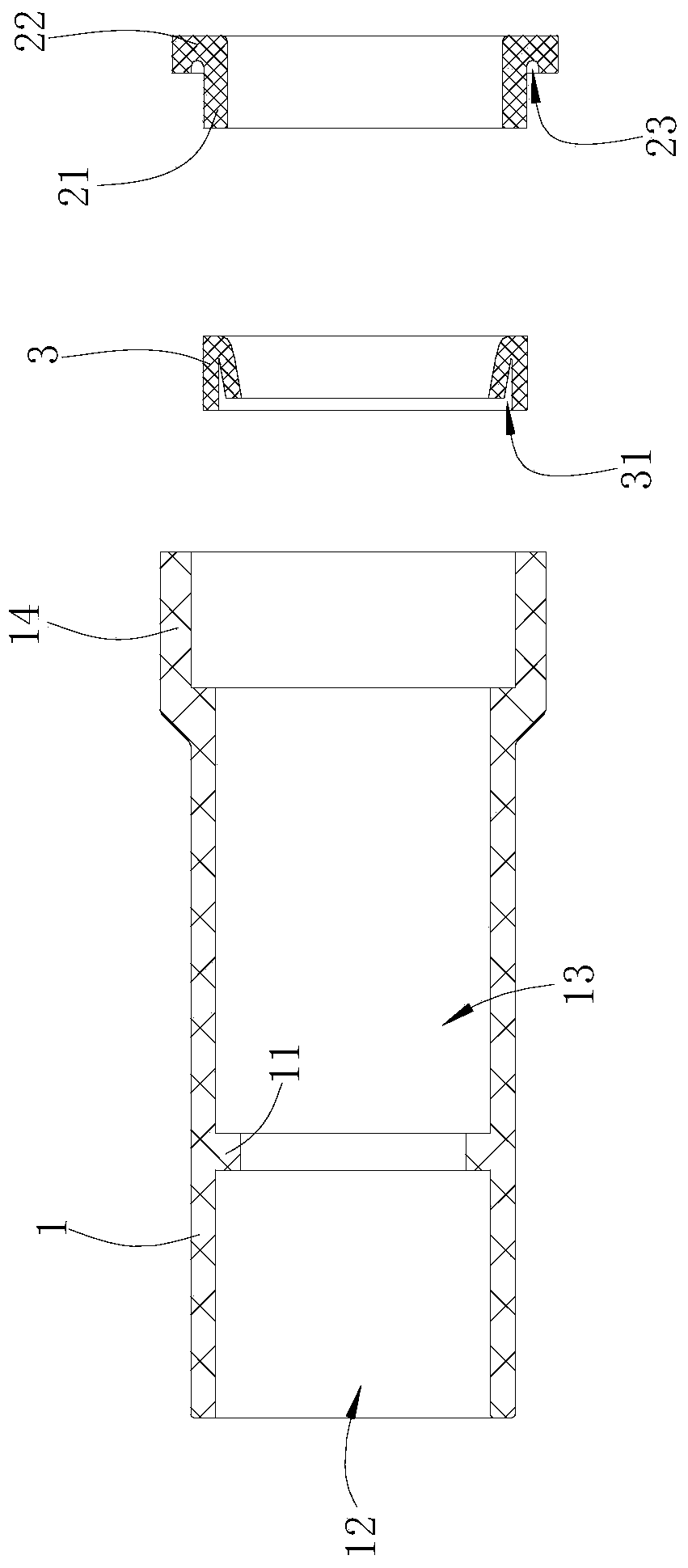

[0027] Such as Figures 1 to 3 shown

[0028] The drinking water pipe sealing expansion joint comprises a connecting sleeve 1, a V-shaped sealing ring 3 and an end cover 2.

[0029] The diameter of the inner hole of the connecting sleeve 1 fits the outer diameter of the drinking water pipe 4, and the inner wall of the connecting sleeve 1 extends to limit the convex ring 11. The limiting convex ring 11 divides the inner hole of the connecting sleeve 1 into two interconnected front and rear chambers. The front chamber is a fixed chamber 12, and the rear chamber is a telescopic chamber 13. The rear end of the connecting sleeve 1 also extends with a tubular sealing part 14, and the inner diameter of the sealing part 14 is greater than the inner diameter of the drinking water pipe 4.

[0030] The end cap 2 includes a tubular insertion portion 21 and an annular blocking portion 22 . The diameter of the blocking portion 22 is larger than that of the insertion portion 21 .

[0031] ...

Embodiment 2

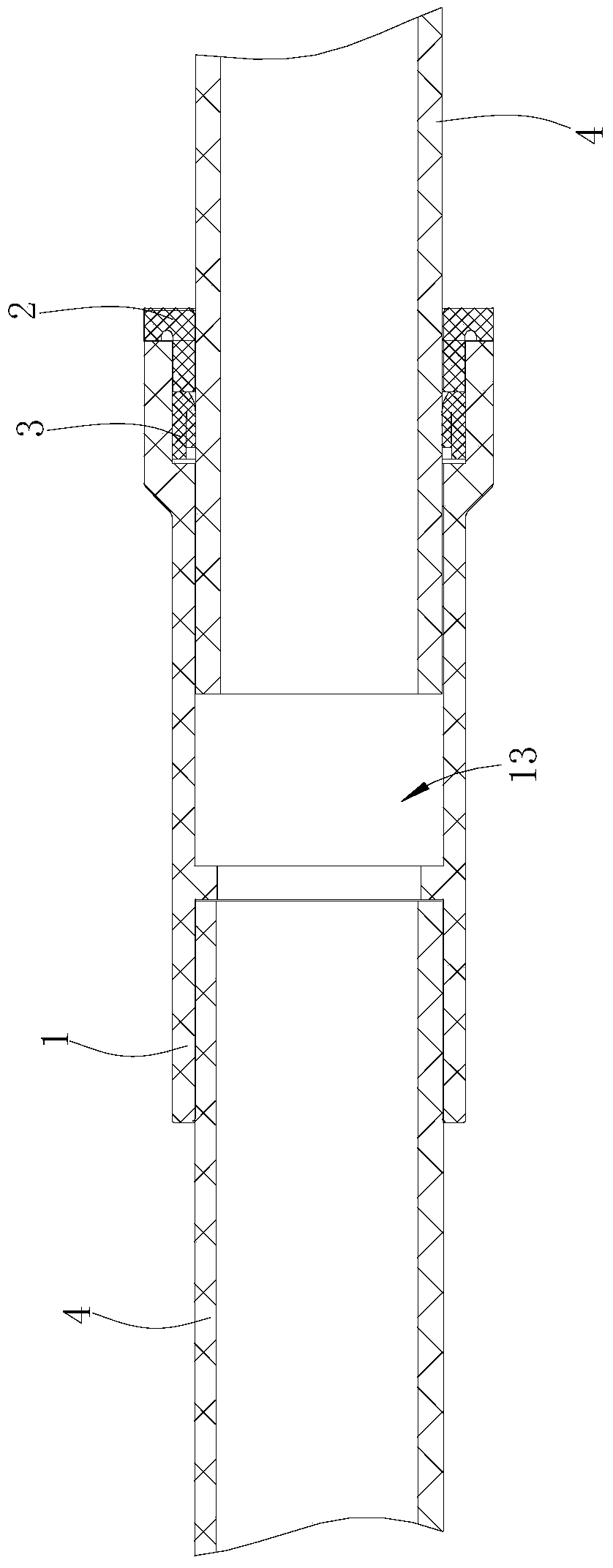

[0036] Such as Figure 4 shown

[0037] The difference between the sealed telescopic drinking water pipe of this embodiment and the first embodiment is that the sealed telescopic joint of the drinking water pipe in the first embodiment is integrated into the water diversion pipe, that is, the pipe body 5' of the sealed telescopic drinking water pipe is extended with a connection Sleeve 1', a tubular sealing part 14' extends from the rear end of the connecting sleeve 1', and only a telescopic chamber 13' is provided in the connecting sleeve 1'. Other structures of the sealed telescopic drinking water pipe are sealed with the drinking water pipe in Embodiment 1. The expansion joints are generally the same, and the use of the V-shaped sealing ring 3' and the end cap 2' is also the same as that of the first embodiment.

[0038] When in use, it can be connected end-to-end successively through multiple fundamentally sealed telescopic drinking water pipes, or cooperate with other co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com