A submersible direct drive screw pump huff and puff oil recovery device

A technology of oil production equipment and screw pump, which is applied in the direction of wellbore/well valve device, production fluid, earthwork drilling and production, etc. It can solve the problems of low construction efficiency, high safety and environmental protection risks, and achieve the improvement of repair-free period and low safety and environmental protection risks , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

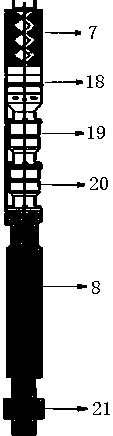

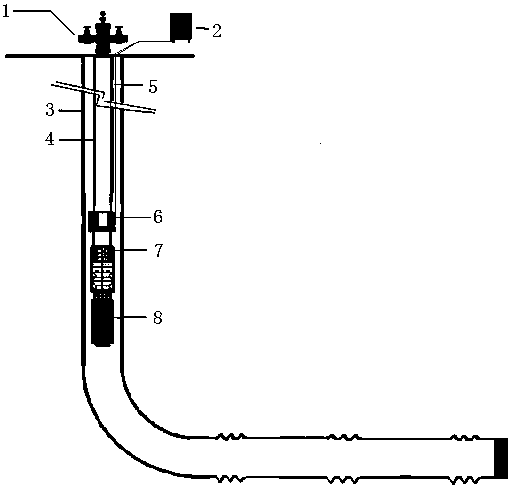

[0019] see figure 2 and image 3 , the present invention provides a submersible direct drive screw pump huff and puff oil production device, including an automatic downhole water injection switch 6 used to switch between water injection and oil production channels and a submersible direct drive screw pump; wherein the upper end of the downhole automatic water injection switch 6 is liquid Port 9 is connected to oil pipe 4, and its lower end liquid inlet 10 is connected to the oil outlet of the upper end of the submersible direct-drive screw pump through oil pipe 4; said submersible direct-drive screw pump includes a screw pump coaxially connected from top to bottom 7. Flexible shaft 18, upper protector 19, lower protector 20, submersible motor 8 and centralizer 21; the upper end of the screw pump 7 is connected to the lower end of the downhole automatic water injection switch 6; the screw pump 7 and the submersible motor 8 are respectively Electric connection leads to the sub...

Embodiment 2

[0022] On the basis of Embodiment 1, the downhole automatic water injection switch 6 includes four functional components of downhole power supply, control circuit, drive motor and mechanical switch located in its working cylinder 11; Connection, the control circuit is electrically connected with the driving motor; the control circuit mainly controls the rotation direction of the motor to realize the conversion of the "water injection-oil production" process. The downhole power supply adopts high-temperature lithium battery, and the ambient temperature range is -20ºC~+150ºC, which can realize high-current continuous discharge and high-pulse current discharge.

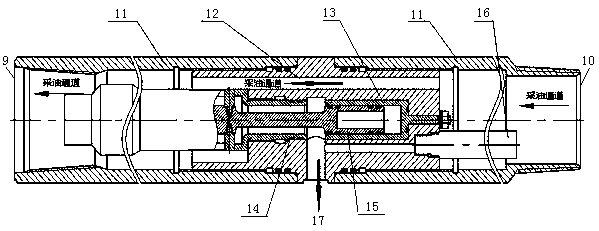

[0023] Such as figure 1 As shown, the mechanical switch includes a bridge channel 12, a lower piston cylinder 13, an upper piston cylinder 14, a piston 15 and a pressure gauge 16, wherein the upper piston cylinder 14 and the lower piston cylinder 13 are located in the working cylinder 11, and the upper piston cylinder 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com