A composite thermal insulation wallboard

A composite thermal insulation and wallboard technology, applied in the field of building materials, achieves the effects of high thermal insulation characteristics, improved bearing capacity and stability, and improved ultimate bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

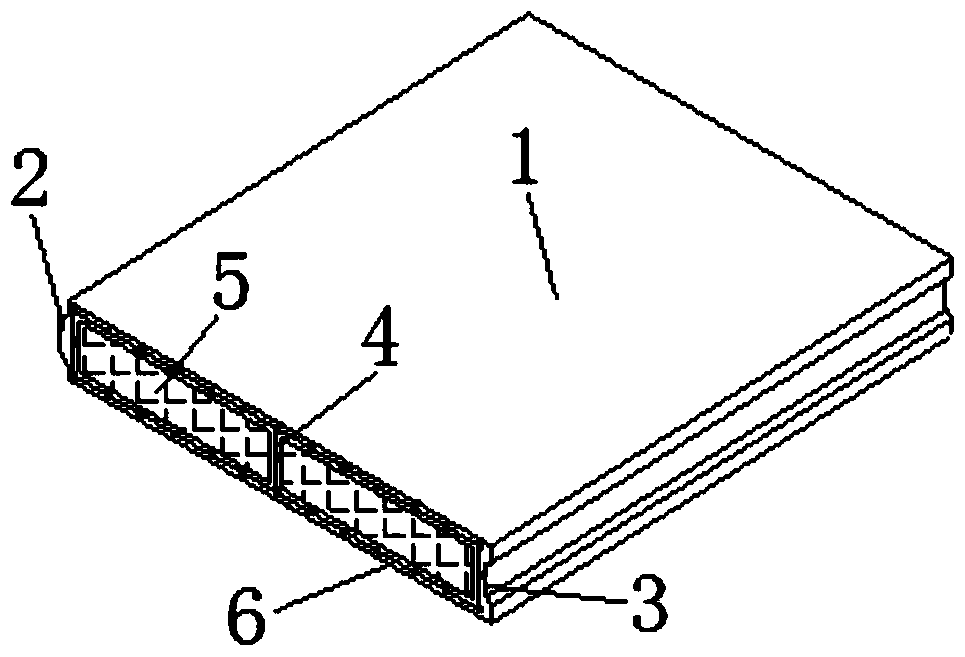

[0061] A composite thermal insulation wallboard, the specific embodiments are as follows:

[0062] Prefabricated wallboard insulation core material 5, its insulation performance and geometric dimensions meet the design requirements; the two sides are respectively reserved with protrusions A7, cross-shaped grooves A8, and circular grooves C9.

[0063] Long-fiber grid 6, the equivalent square side length of a single mesh hole is 25 mm to 100 mm; long-fiber grid 6 is pre-positioned according to the size and position of panel 1 and rib plate, and it is pre-impregnated with resin, and then shaped after hardening.

[0064] Lay the bottom mold 15 with the raised platform B13, move the thermal insulation core material 5 into the long-dimensional fiber grid 6, and then align the circular groove C9 on the thermal insulation core material 5 with the upper convex platform B13 of the bottom mold 15 to ensure that the bottom mold 15 The upper protrusion B14 is inserted into the circular gro...

Embodiment approach 2

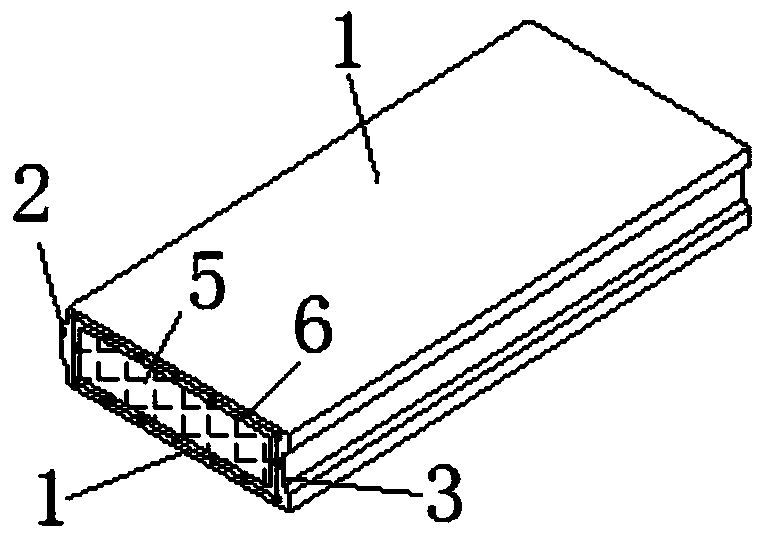

[0069] A composite thermal insulation wallboard, the specific embodiments are as follows:

[0070] According to the design size of the wallboard insulation core material, select the inflatable inner mold.

[0071] Long-fiber grid 6, the equivalent square side length of a single mesh hole is 25 mm to 100 mm; long-fiber grid 6 is pre-positioned according to the size and position of the panel and rib plate, and is pre-impregnated with resin, and then shaped after hardening.

[0072] Put the inflatable template 16 inside the long fiber grid 6, fix it temporarily, inflate and seal it, and lay the bottom mold 15 with the boss B13. Put the long fiber grid 6 with the inflatable inner mold 16 into the bottom mold 15 with the boss B13. If any fiber mesh passes through the range of the raised platform B13, then single fiber is put into the cross-shaped groove B14 on the raised platform B13 on the bottom mold 15, temporarily fixed.

[0073] Stretch the elongated fiber grid 6 to a certai...

Embodiment approach 3

[0077] A composite thermal insulation wallboard, the specific embodiments are as follows:

[0078] Prefabricated wallboard insulation core material 5, its insulation performance and geometric dimensions meet the design requirements; the two sides are respectively reserved with protrusions A7, cross-shaped grooves A8, and circular grooves C9.

[0079] The two-dimensional long-fiber grid 17 has an equivalent square side length of 25 mm to 100 mm for a single mesh; the two-dimensional long-fiber grid 17 matches the size and position of the panel and the rib plate, and is pre-impregnated with resin, and then shaped after hardening.

[0080] Wrap the two-dimensional fiber grid 17 horizontally along the heat preservation core material 5, and bind and overlap at one side panel.

[0081] Lay the bottom mold 15 with the raised platform B13, move the thermal insulation core material 5 into the long fiber grid 6, and then align the circular groove C9 on the thermal insulation core materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com