Lateral prestress application method for paving reinforcing bar concrete on bridge floor of assembled type bridge

A lateral prestressed, reinforced concrete technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of weak lateral connections, insufficient bridge bearing capacity, poor lateral load distribution capacity, etc., and achieves simple materials and construction equipment. , the effect of increasing the bridge safety factor and high technical maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

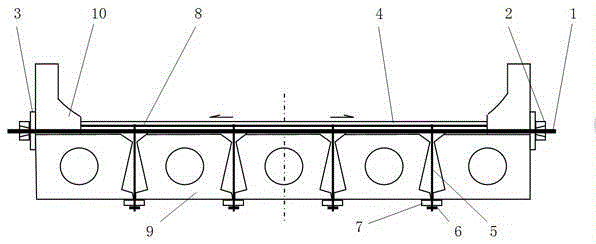

[0039] Example: (see figure 1 )

[0040] A prestressed concrete hollow slab bridge with a bridge width of 10m (the width of the bridge deck is 9m + the width of the anti-collision belt 10 is 2×0.5m), the longitudinal level is horizontal, and the transverse slope is 1.5%. Length × width × thickness = 1996cm × 99cm × 85cm, the load is road— Level, hinge joint concrete and bridge deck pavement concrete 4 and anti-collision strip 10 concrete are C40 respectively;

[0041] The original bridge deck pavement concrete 4 is cut at the bridge deck joint, the hinge joint concrete and the original bridge deck pavement concrete 4 have been chiseled off, and the connection between the bridge decks has been disconnected;

[0042] It is required to use the original bridge slab, and apply transverse prestress to the bridge deck pavement for reconstruction; the center spacing of the steel mesh reinforcement is 10cm, and the center spacing of the horizontal steel strands 1 is not greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com