A design method for the ratio of construction waste to asphalt mixture

A technology for asphalt mixture and construction waste, which is used in construction, on-site coagulation pavement, roads, etc., can solve the problems of different properties of construction waste and lack of sufficient consideration of the characteristics of construction waste, and achieves significant environmental protection. Ensure possibility and feasibility, expand the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

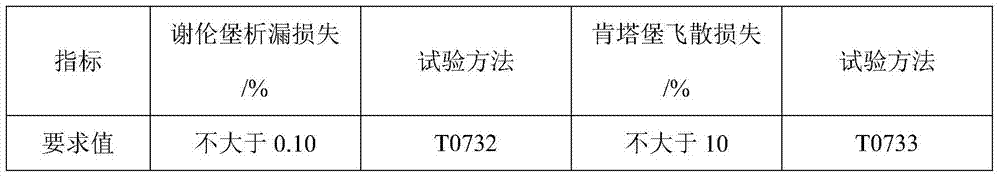

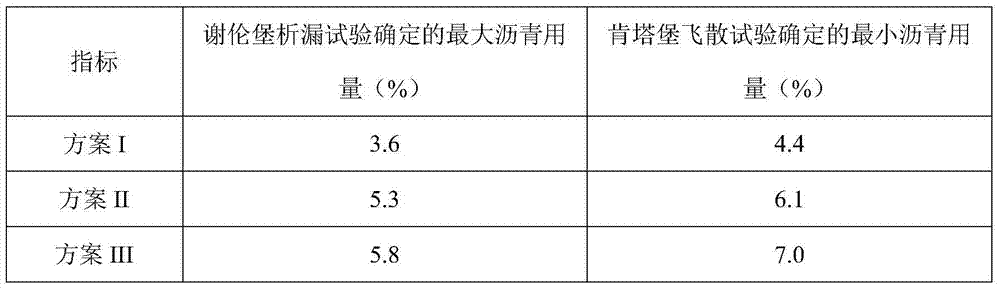

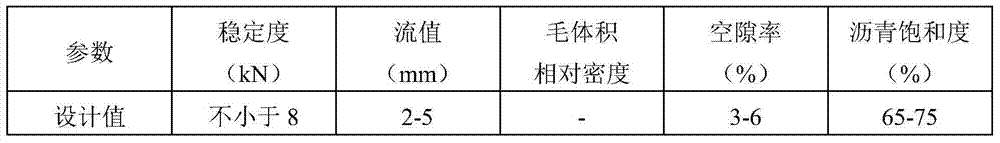

[0058] Below by a mixing ratio design implementation example, further parameter the present invention.

[0059] Design the gradation with AC-20 as the target, and design the mix ratio of construction waste asphalt mixture. The mix ratio of the asphalt mixture is designed for the lower layer of the secondary road.

[0060] Selection of Raw Materials for Asphalt Mixture

[0061] (1) Selection of mineral material specifications

[0062] According to the asphalt mixture design target - AC-20 asphalt mixture;

[0063] Aggregate specifications: 0-3mm construction waste fine aggregate, 0-3mm stone chips, 3-5mm crushed stone, 5-15mm crushed stone, 10-20mm crushed stone, limestone mineral powder.

[0064] (2) Asphalt is 70#A grade petroleum asphalt.

[0065] Asphalt mixture gradation design. The gradation design is carried out with the median value of the AC-20 gradation curve as the target value of the gradation design; the gradation curve is prepared from a new aggregate, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com