Application of moisture absorbing and sweat releasing finishing agent to polyester fiber materials

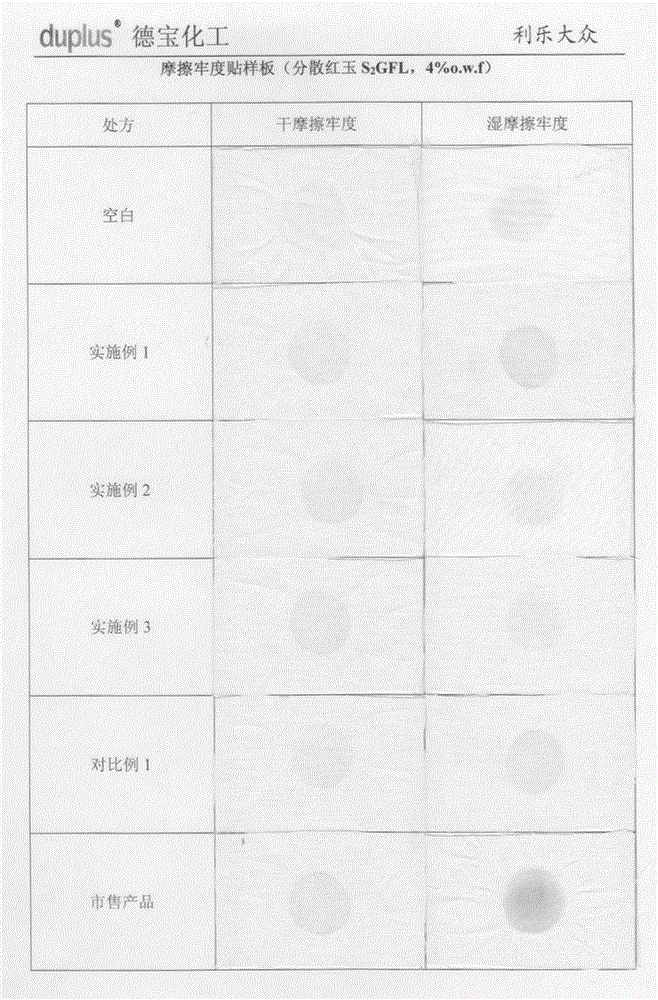

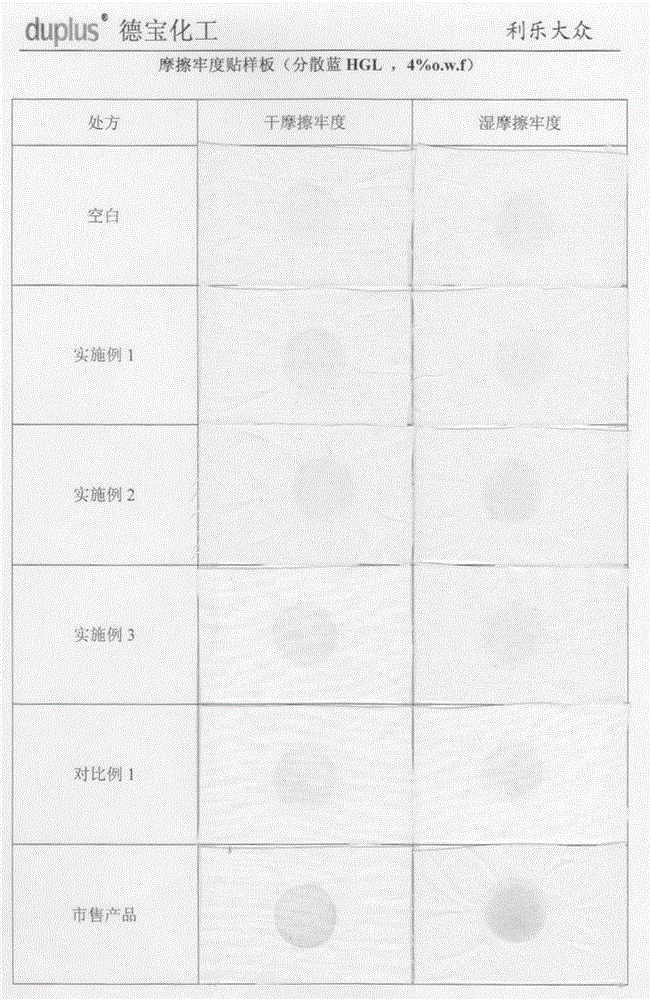

A technology of moisture absorption and perspiration, fiber material, which is applied in the application field of moisture absorption and perspiration finishing agent in polyester fiber materials, can solve the problems of reduced color fastness, etc., to improve hydrophilicity and solve the problem of reduced color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 500g of dimethyl terephthalate, 500g of N,N'-dihydroxypyromellitic acid imide, 2000g of propylene glycol block polyether with a molecular weight of 2000, 2500g of polyethylene glycol with a molecular weight of 1000, 1500g of ethylene glycol, Magnesium acetate 50g;

[0030] Put the above materials into the reaction kettle, raise the temperature to 150°C and keep it for 180 minutes, continue to raise the temperature to 220°C and keep it for 60 minutes, then polymerize it into a polyester polyether with an average molecular weight of 10,000 at a vacuum degree of -0.08MP and a temperature of 230°C The block copolymer is discharged after cooling down to 100°C to obtain the target product.

Embodiment 2

[0032] Weigh 1000g of dimethyl terephthalate, 400g of N,N'-dihydroxypyromellitic acid imide, 2500g of propylene glycol block polyether with a molecular weight of 1000, 5000g of polyethylene glycol with a molecular weight of 2000, 4000g of ethylene glycol, Zinc acetate 100g;

[0033] Put the above materials into the reaction kettle, raise the temperature to 180°C and keep it for 250 minutes, continue to raise the temperature to 230°C and keep it for 90 minutes, and then polymerize it into a polyester polyether with an average molecular weight of 18000 at a vacuum degree of -0.1MP and a temperature of 240°C The block copolymer is discharged after cooling down to 120°C to obtain the target product.

Embodiment 3

[0035] Weigh 800g of dimethyl terephthalate, 200g of N,N'-dihydroxypyromellitic acid imide, 3000g of propylene glycol block polyether with a molecular weight of 500, 10000g of polyethylene glycol with a molecular weight of 4000, 3000g of ethylene glycol, Tin acetate 20g;

[0036] Put the above materials into the reaction kettle, raise the temperature to 170°C and keep it for 200 minutes, continue to raise the temperature to 230°C and keep it for 80 minutes, and then polymerize it into a polyester polyether with an average molecular weight of 15,000 at a vacuum degree of -0.1MP and a temperature of 250°C The block copolymer is discharged after cooling down to 110°C to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com