A kind of preparation method of dyeable polyurethane elastic fiber

A polyurethane elastic and fiber technology, which is applied in the field of polymer material preparation, can solve the problems of insufficient printing and dyeing effect, complicated adding process, general printing and dyeing effect, etc., to improve dyeability and color fastness, low cost, and easy to promote Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

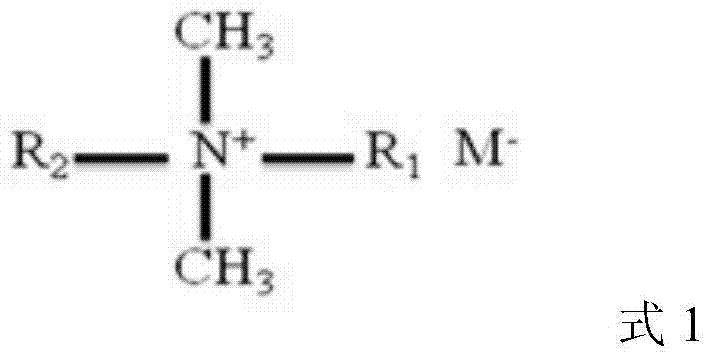

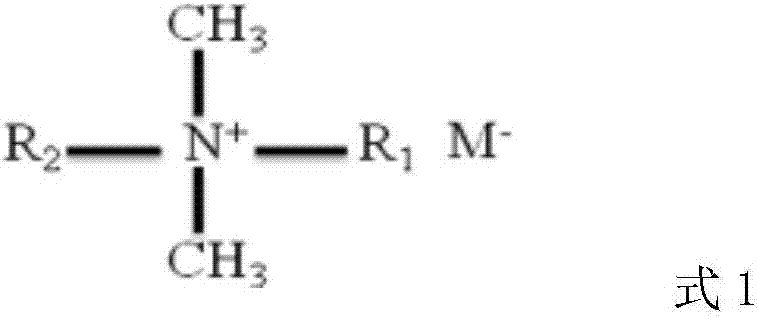

Method used

Image

Examples

Embodiment 1

[0031] 1) Mix the raw materials polytetramethylene ether glycol and 4,4'-diphenylmethane diisocyanate, and react at 90°C for 120 minutes to prepare a prepolymer, in which 4,4'-diphenylmethane diisocyanate and The molar ratio of polytetramethylene ether glycol is 1.70:1;

[0032] 2) Preparation of mixed amine solution: dissolve ethylenediamine and propylenediamine in a molar ratio of 4:1 into the solvent N,N-dimethylacetamide, and then add diethylamine with a diamine molar content of 15% to form a mass A mixed amine solution with a percentage concentration of 6.00%;

[0033] 3) Add the mixed amine solution into the prepolymer solution and stir, wherein the molar ratio of the amine group to the isocyanate group is 1.07:1, and react to form a concentration of 35% by mass polymer solution;

[0034] 4) Preparation of easy-to-dye auxiliaries slurry: based on the solid content of the polymer, 0.5 wt% of 2-(2'-hydroxy-3', 5'-di-tert-butylphenyl)-benzotriazole) , 0.5wt% bis (N, N-di...

Embodiment 2

[0037] A solution was obtained in the same manner as described in Example 1, except that the addition amount of octadecyltrimethylammonium chloride was 5.0 wt%. After 35 hours of stirring and aging, the dyeable polyurethane elastic fiber is formed by dry spinning. Example 3:

Embodiment 3

[0038] A solution was obtained in the same manner as described in Example 1 except that the addition amount of octadecyltrimethylammonium chloride was 10.0 wt%. After 35 hours of stirring and aging, the dyeable polyurethane elastic fiber is formed by dry spinning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com