Movable floor stand for aluminum product oxidation shelving

An aluminum material and racking technology, which is applied in the field of aluminum product processing, can solve the problems of difficult operation of aluminum material loading, clamping and unloading, poor applicability of racking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

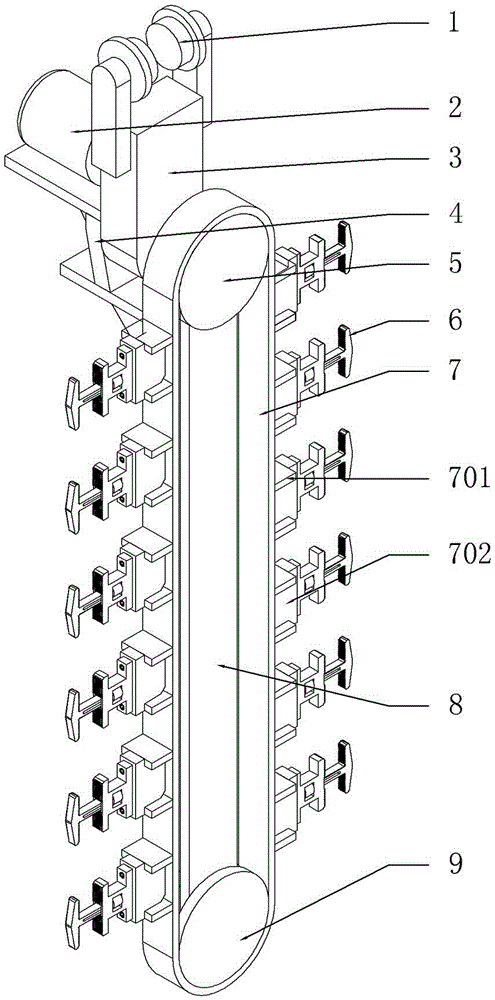

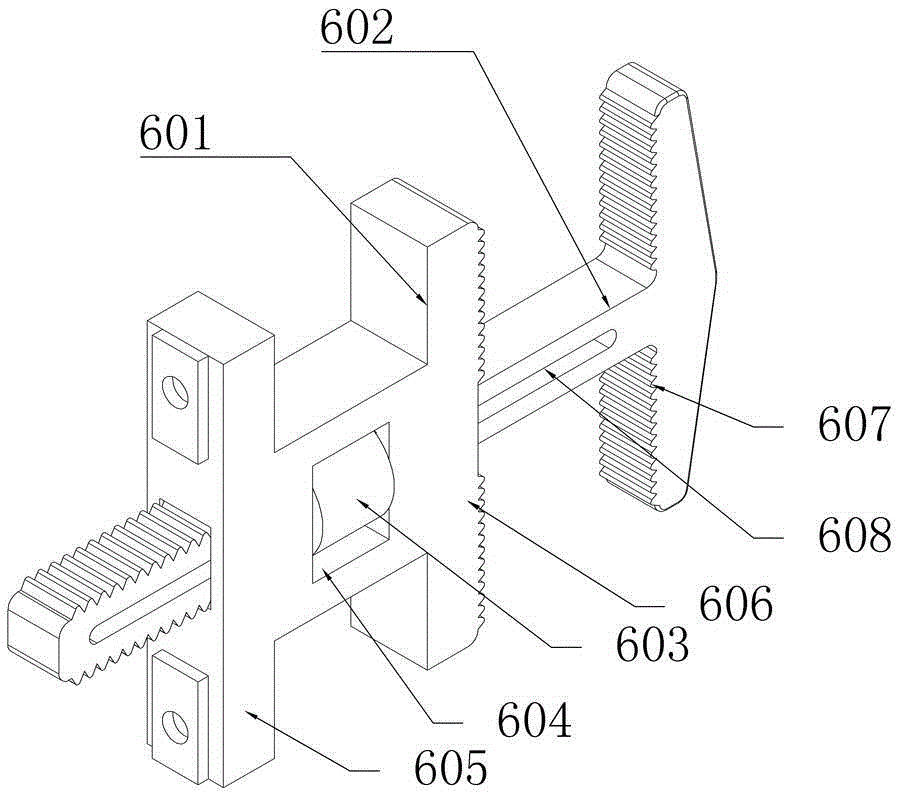

[0015] The reference signs in the drawings of the description include: roller 1, motor 2, shifter 3, connecting seat 4, driving sprocket 5, clamp 6, pliers sleeve 601, movable pliers body 602, adjusting nut 603, adjusting nut groove 604 , Mounting plate 605, fixed plate 606, movable plate 607, slotting 608, chain 7, chain plate 701, mounting seat 702, brace plate 8, driven sprocket 9.

[0016] like figure 1 Shown: the mobile stand used for aluminum oxidation racking, including the connecting seat 4, the connecting seat 4 is provided with a motor 2, a moving mechanism and a chain support, and the output end of the motor 2 is provided with a power switch to The shifter 3 of the moving mechanism or chain support; the shifter 3 includes a gear set, a shift fork connected with the gear set, and a power output shaft connected with the motor 2, and the power output shaft is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com