A graphite deposition device for a chemical vapor deposition furnace

A chemical vapor deposition and deposition device technology, applied in the field of graphite deposition devices for chemical vapor deposition furnaces, can solve problems such as inconvenient operation, uneven product thickness, and reduced product utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] First, put the solid raw material into the graphite crucible of the solid raw material holding device, cover the crucible lid on the top, and confirm that the airflow holes on the top of the crucible lid are in good condition.

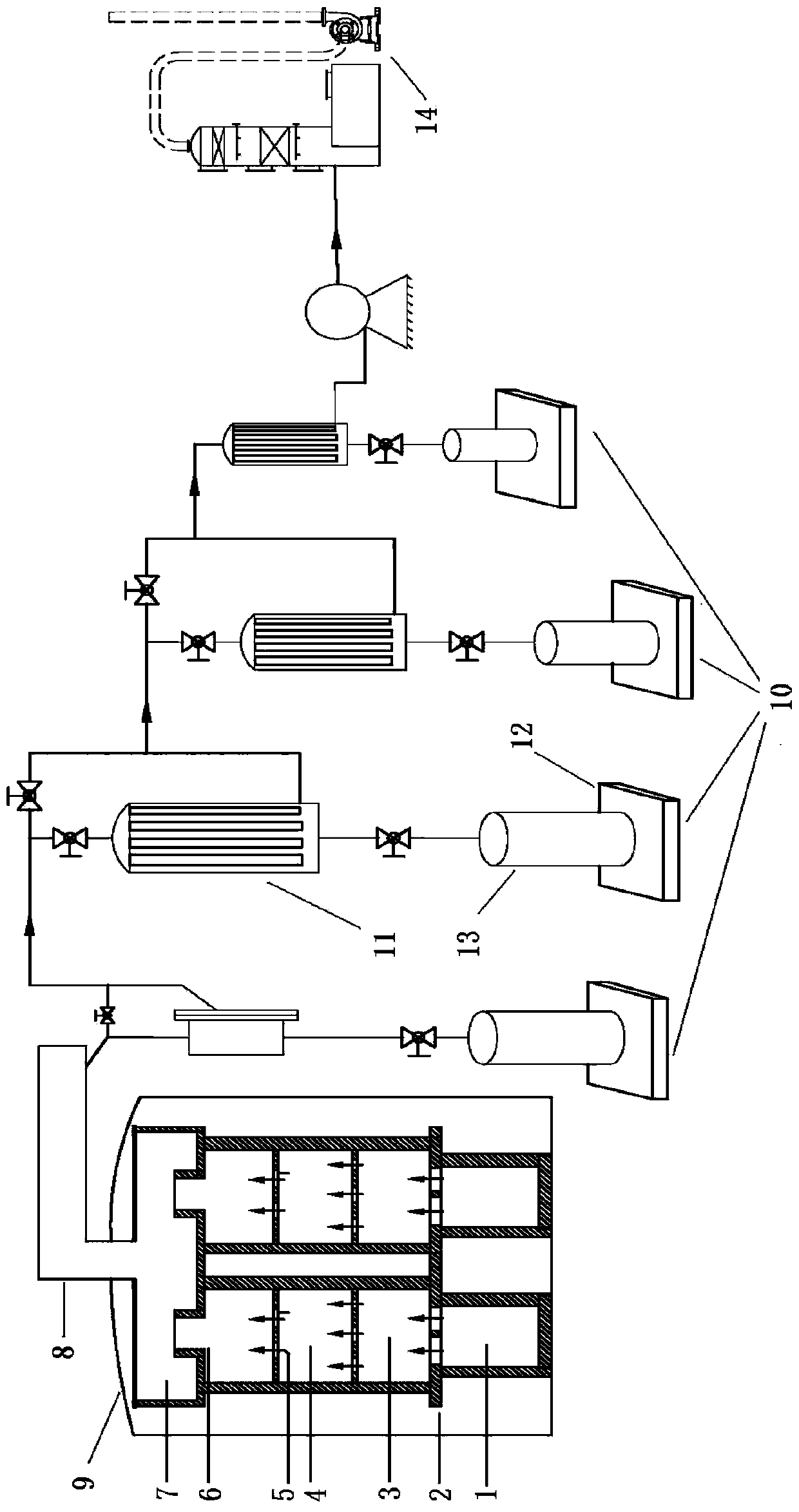

[0064] Then set the temperature rise and deposition procedures of the chemical vapor deposition furnace. During the deposition process, the solid raw material vapor and gas raw materials are carried by inert gas and enter the first deposition chamber through the pores. After the deposition part of the bottom cover of the first deposition chamber, Then enter the second deposition chamber through the airflow holes on the partition (arranged alternately with the airflow holes on the cover). After the bottom partition of the second deposition chamber is deposited, it finally passes through the airflow holes on the partition (the first The bottom partition of the second deposition chamber and the airflow holes on the bottom partition of the third deposit...

Embodiment 2

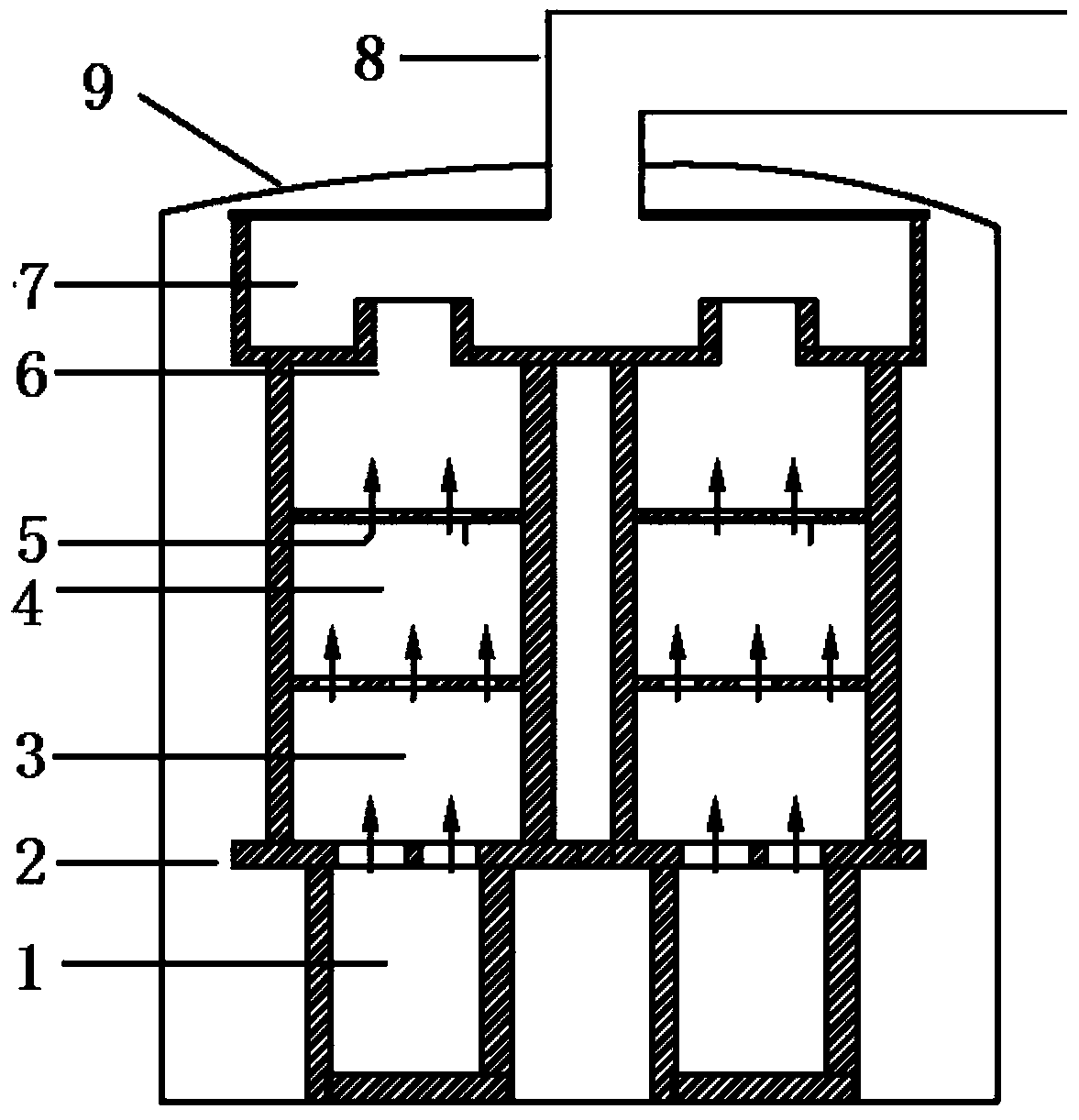

[0067] Load the zinc raw material into the graphite crucible, set the temperature rise and deposition program, during the deposition process, hydrogen selenide and zinc vapor enter the deposition chamber under the inert gas, first enter the first deposition chamber, and deposit part in the first deposition chamber , And then enter the second deposition chamber through the gas splitter plate for deposition. After the deposition part of the bottom partition of the second deposition chamber, enter the third deposition chamber through the gas flow holes on the partition, and deposit in the third deposition chamber. On the bottom partition of the third deposition chamber. Finally, the unreacted gas and undeposited zinc selenide dust enter the dust collection chamber for deposition, and then pass through the dust guide channel to enter the back-end dust multi-stage collection system and tail gas treatment system after the chemical deposition process.

[0068] See figure 2 , figure 2 ...

Embodiment 3

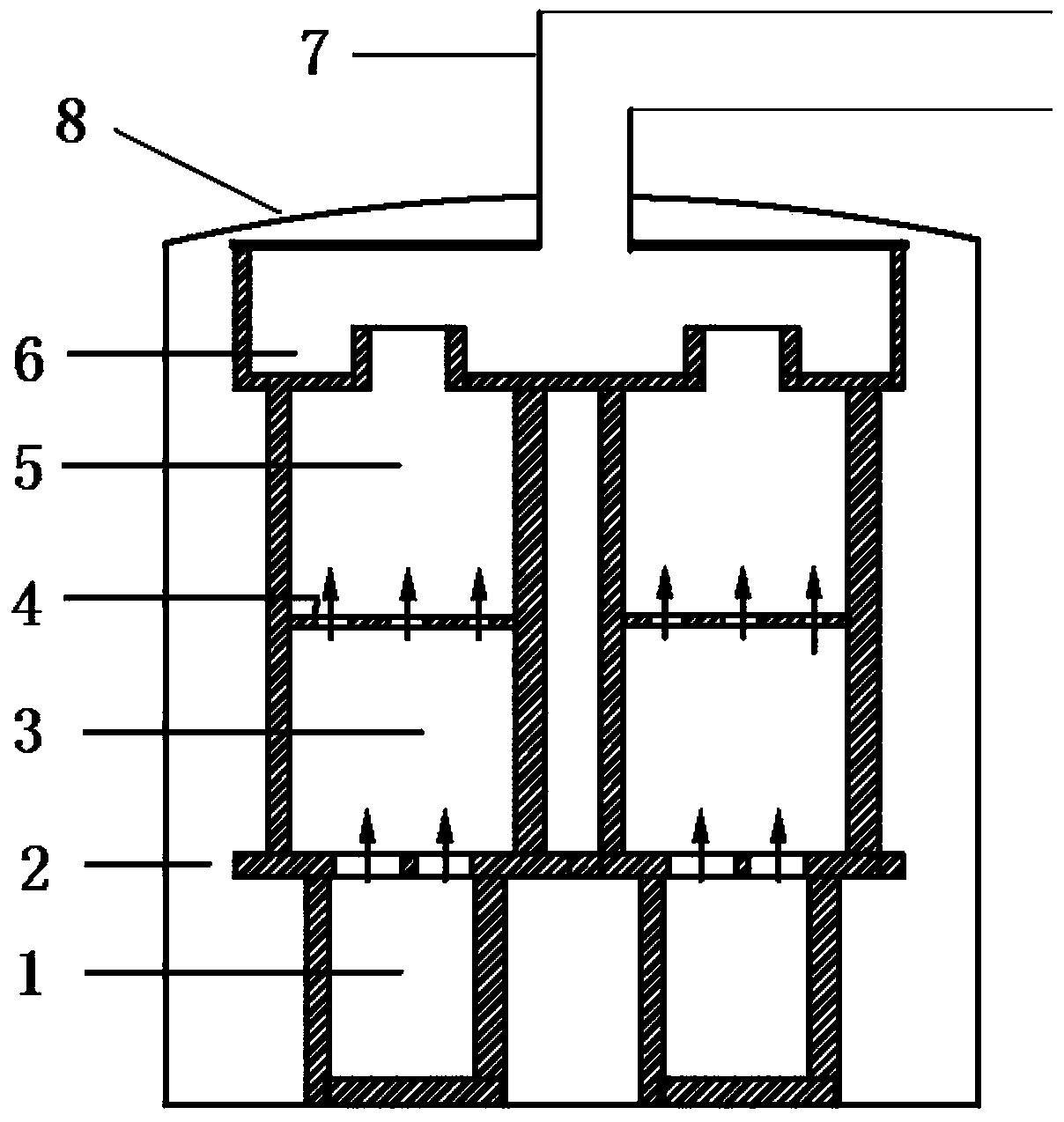

[0072] Load the zinc raw material into the graphite crucible, set the temperature rise and deposition program, during the deposition process hydrogen sulfide and zinc vapor enter the deposition chamber under the inert gas, first enter the first deposition chamber, in the first deposition chamber, the deposition part, Then enter the second deposition chamber through the gas splitter plate for deposition, and finally the unreacted gas and undeposited zinc sulfide dust enter the dust collection chamber for deposition, and then enter the back end dust collection system after the chemical deposition process through the dust guide channel And exhaust gas treatment system.

[0073] See image 3 , image 3 This is a schematic diagram of the structure of a graphite deposition apparatus for a chemical vapor deposition furnace provided in Example 3 of the present invention, where 1 is a crucible, 2 is a crucible cover, 3 is a first deposition chamber, 4 is a partition, and 5 is a second I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com