Environment-friendly oil paint for steel structure and preparation method of oil paint

A steel structure and paint technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as low hardness, poor environmental protection, and strong odor, and achieve the effect of comprehensive ingredients, good applicability, and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

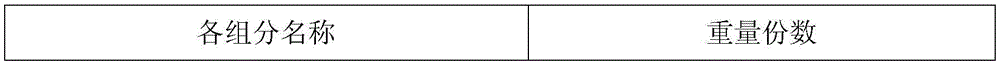

[0026] Embodiment 1 A kind of paint for environmental protection steel structure, its each raw material composition component and weight parts are as follows table:

[0027] Ingredients:

[0028]

[0029]

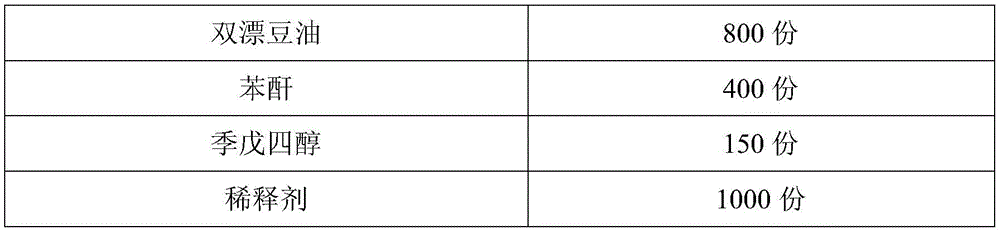

[0030] Ingredients:

[0031] Component name

parts by weight

resin

50 copies

Dispersant

0.4 parts

leveling agent

0.4 parts

0.4 parts

Titanium dioxide

15 copies

brightener

4 parts

8 servings

Thinner

1.5 servings

Nano dry material

1 copy

[0032] Preparation:

[0033] (1), mixing of main ingredients: First, weigh 800 kilograms of double-bleached soybean oil, 400 kilograms of phthalic anhydride, 150 kilograms of pentaerythritol, and 1000 kilograms of diluent according to the above proportions, put the double-bleached soybean oil in the main ingredients into the reaction kettle, and start stirring to heat up. Add pentaer...

Embodiment 2

[0036] Embodiment 2 A kind of paint for environment-friendly steel structure, its each raw material component component and parts by weight are as follows:

[0037] Ingredients:

[0038] Component name

parts by weight

double bleached soybean oil

1000 copies

500 copies

pentaerythritol

200 copies

Thinner

1300 copies

[0039] Ingredients:

[0040] Component name

parts by weight

resin

60 copies

Dispersant

0.5 parts

leveling agent

0.5 parts

0.5 parts

Titanium dioxide

20 copies

brightener

5 copies

10 copies

Thinner

2 copies

Nano dry material

1.5 servings

[0041] Preparation:

[0042] (1), mixing of main ingredients: First, weigh 1000 kilograms of double-bleached soybean oil, 500 kilograms of phthalic anhydride, 200 kilograms of pentaerythritol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com