Method for extracting natural vitamin E through two-step reextraction method

A natural vitamin and extraction technology, which is applied in the field of two-step back extraction to extract natural vitamin E, can solve the problems of large amount of organic solvent, difficult separation, high content of esters, etc., and achieve simple operation, high extraction efficiency, and reduced dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

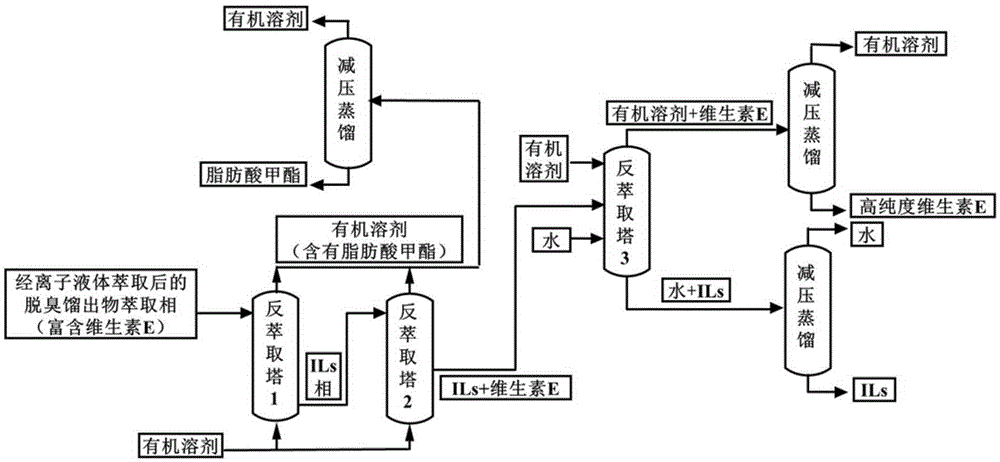

Method used

Image

Examples

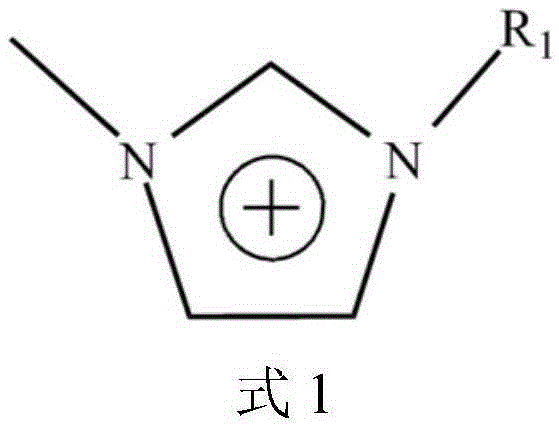

Embodiment 1

[0033] Contain 86.25% of 1-pentyl-3 methylimidazole acetate [C 5 MIm]Ac ionic liquid, 4.81% α-tocopherol and 8.94% methyl linoleate were deodorized distillate model oil extracts for a two-step stripping operation. n-pentane was used as the organic solvent in the stripping process. In the first step back extraction process, the mass ratio of stripping agent (organic solvent) and extraction phase is 10%, after 3 back extractions and adopting decantation method to separate, the raffinate phase is carried out the second step back extraction, wherein The mass ratio of n-pentane: water: raffinate phase is 0.1:0.3:1, the organic solvent phase is obtained by decantation, and the product of vitamin E is obtained by distillation under reduced pressure at 10KPa and 40°C, and the recovery rate is 97.3% , the concentration is 94.5%, and the concentration of methyl linoleate is 5.5%. The extractant ILs in the aqueous phase is also recovered by vacuum distillation, the operating pressure i...

Embodiment 2

[0035] Contain 81.42% of 1-hexyl-3 methylimidazole acetate [C 6 MIm]Ac ionic liquid, 8.30% α-tocopherol and 10.28% methyl linoleate deodorized distillate model oil extract was subjected to two-step stripping operation. Using n-hexane as the organic solvent in the stripping process. In the first step back extraction process, the mass ratio of back extraction agent (organic solvent) and extraction phase is 20%, after 3 times of back extraction and separation by decantation, the raffinate phase is carried out the second step back extraction, wherein n-Hexane: water: the mass ratio of the raffinate phase is 0.2:0.6:1, the organic solvent phase is obtained by decantation, at 1KPa, under reduced pressure distillation at 40°C, the product of vitamin E is obtained, and the recovery rate is 98.7%. The concentration is 99.2%, and the methyl linoleate concentration is 0.8%. The extractant ILs in the aqueous phase is also recovered by vacuum distillation, the operating pressure is 1KPa,...

Embodiment 3

[0037] Contain 80.65% of 1-heptyl-3 methylimidazole acetate [C 7 MIm]Ac ionic liquid, 4.28% α-tocopherol and 15.07% methyl linoleate deodorized distillate model oil extract was subjected to two-step stripping operation. N-heptane was used as the organic solvent in the stripping process. In the first step back extraction process, the mass ratio of back extraction agent (organic solvent) and extraction phase is 40%, after 2 times of back extraction and separation by decantation, the raffinate phase is carried out the second step back extraction, wherein The mass ratio of n-heptane: water: raffinate phase is 0.4:0.8:1, the organic solvent phase is obtained by decantation, and the product of vitamin E is obtained by distillation under reduced pressure at 1KPa and 70°C, and the recovery rate is 97.5% , the concentration is 98.4%, and the concentration of methyl linoleate is 1.6%. The extractant ILs in the aqueous phase is also recovered by vacuum distillation, the operating press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com