A treatment method for high oil and poly-containing sewage

A treatment method and technology for sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of reducing quantity and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

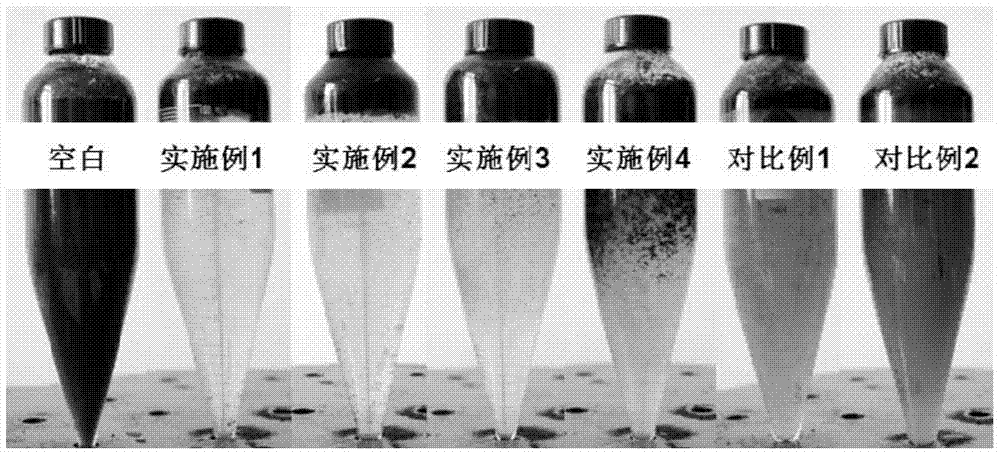

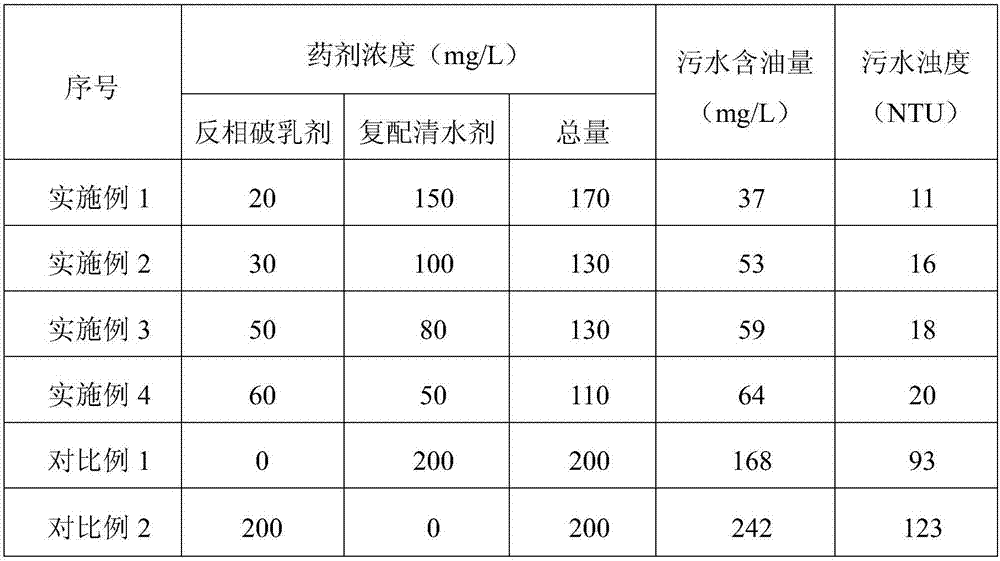

Examples

Embodiment 1

[0043] Take 100mL of oil field site poly-containing sewage, and place it in a 65°C water bath for half an hour at a constant temperature, and the following treatment temperatures are 65°C. Add 20mg / L of cationic polyether type quaternary ammonium salt, artificially shake for 1min, then add 150mg / L of weak cationic polyacrylamide / polyoxyethylene-polyoxypropylene-polyoxyethylene block polyether compound water purifier (mass Ratio is 2:1), after artificial shaking for 1min, observe the water color and flocs, and measure the oil content and turbidity of the sewage.

Embodiment 2

[0045] Take 100mL of oil field site poly-containing sewage, and place it in a 65°C water bath for half an hour at a constant temperature, and the following treatment temperatures are 65°C. Add 30mg / L cationic polyether type quaternary ammonium salt, mechanically shake for 1min, then add 100mg / L weak cationic polydimethyldiallylammonium chloride / polyoxyethylene-polyoxypropylene-polyoxyethylene block Polyether compound water purifying agent (mass ratio 3:1), observe water color and flocs after mechanical shaking for 1 min, and measure oil content and turbidity of sewage.

Embodiment 3

[0047] Take 100mL of oil field site poly-containing sewage, and place it in a 65°C water bath for half an hour at a constant temperature, and the following treatment temperatures are 65°C. Add 50mg / L cationic polyether type quaternary ammonium salt, artificially shake for 2min, then add 80mg / L weak cationic polydimethyldiallylammonium chloride / polyoxypropylene-polyoxyethylene copolymer compound water purifier (Mass ratio is 4:1), artificially shake for 1min to observe the water color and flocs, and measure the oil content and turbidity of the sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com