Cubic CaCO3 and SiO2 composite particles and preparing method thereof

A composite particle and cube-shaped technology, applied in the direction of silica, calcium carbonate/strontium/barium, nanotechnology, etc., can solve problems such as complex operation, different crystal forms, and uneven particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

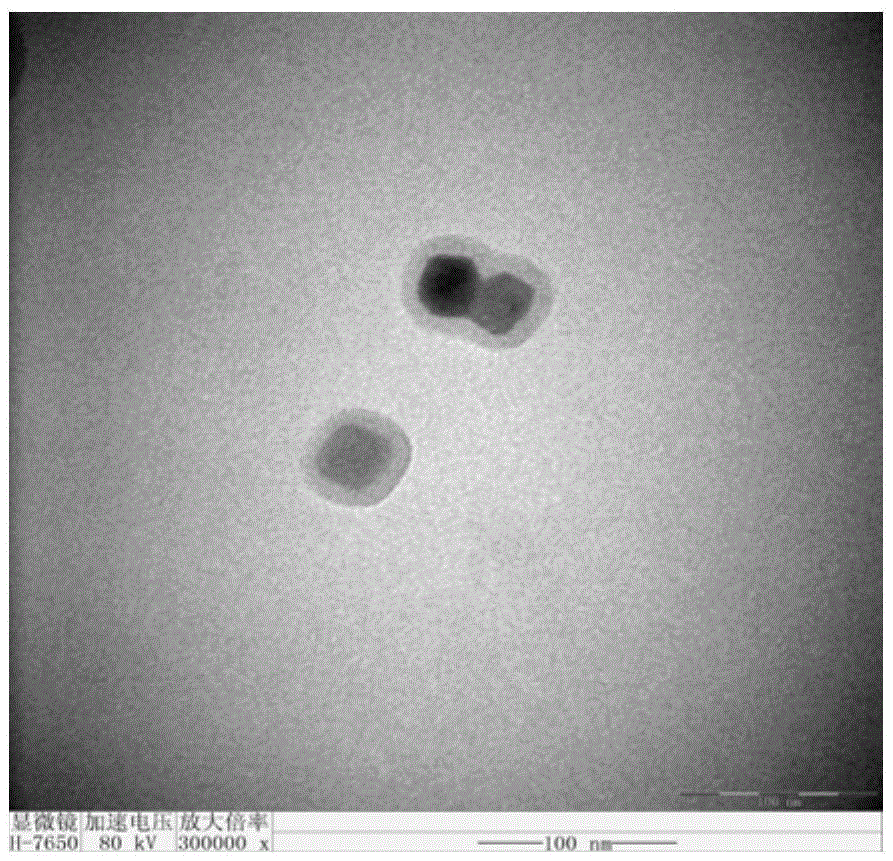

Embodiment 1

[0031] Put 8.74g of quicklime into 280g of water at 80°C, and digest it in a dispersion plate at a speed of 1000rpm for 2h; pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, and then add water to make a suspension with a mass fraction of 4wt%. , aged for 24 hours, and set aside;

[0032] the calcium hydroxide suspension in the step is dispersed in a dispersing disk with a rotating speed of 1000rpm in a linear cut, and 0.52g of 30% sulfuric acid solution is added to control the carbonization temperature to be 15°C, and a certain flow rate ( 60 / 120m 3 .h -1 .m -3 Suspension) CO 2 and N 2 The mixed gas is carbonized; after starting the carbonization reaction for 5min, add 1.04g30% PEG-600 and 15.60g20% silica sol solution (its SiO 2 The average particle size is 5-10nm, the pH is 9.0-10.5), and finally carbonized to pH = 7.0 to obtain the nanocomposite particle slurry;

[0033] Heat the slurry water bath in step to 80°C, and pass a small am...

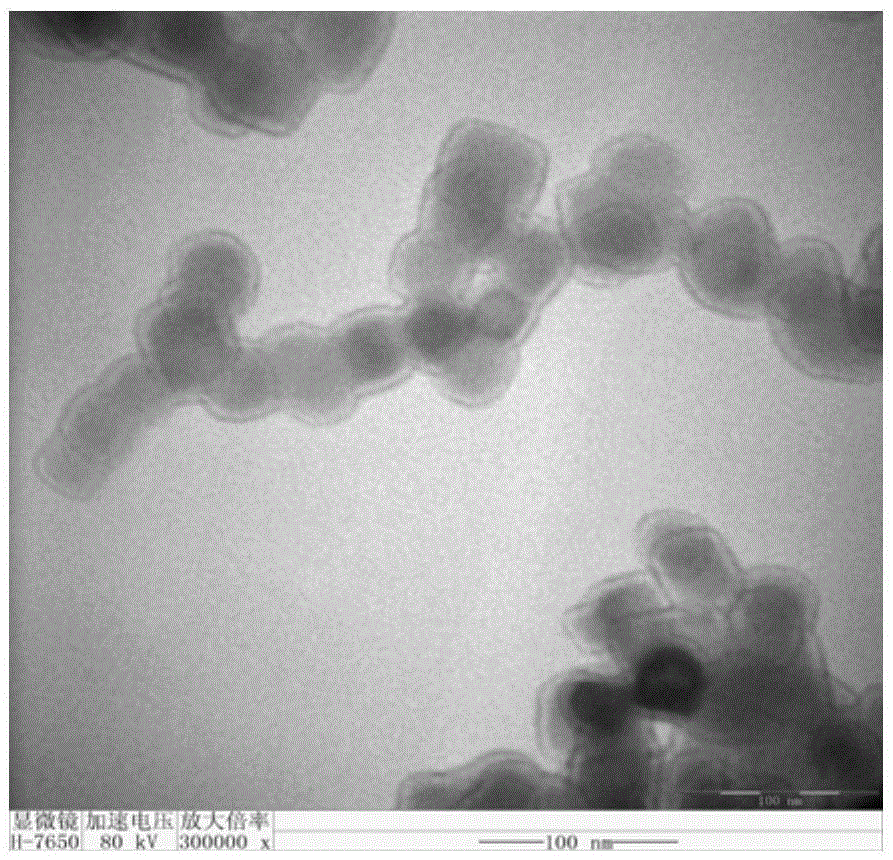

Embodiment 2

[0036] Put 13.32g of quicklime into 280g of water at 80°C, and digest it in a dispersion plate at a speed of 1000rpm for 2h; pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, and then add water to make a suspension with a mass fraction of 6wt%. , aged for 24 hours, and set aside;

[0037] the calcium hydroxide suspension in the step is dispersed in a dispersing disk with a rotating speed of 1000rpm in a linear cut, and 0.63g of 30% sulfuric acid solution is added to control the carbonization temperature to be 14°C, and a certain flow rate ( 60 / 120m 3 .h -1 .m -3 Suspension) CO 2 and N 2 The mixed gas is carbonized; after starting the carbonization reaction for 5min, add 1.19g30% PEG-1000 and 17.83g20% silica sol solution (its SiO 2 The average particle size is 10-20nm, the pH is 9.0-10.5), and finally carbonized to pH = 7.0 to obtain the nanocomposite particle slurry;

[0038] Heat the slurry water bath in step to 80°C, and pass a small...

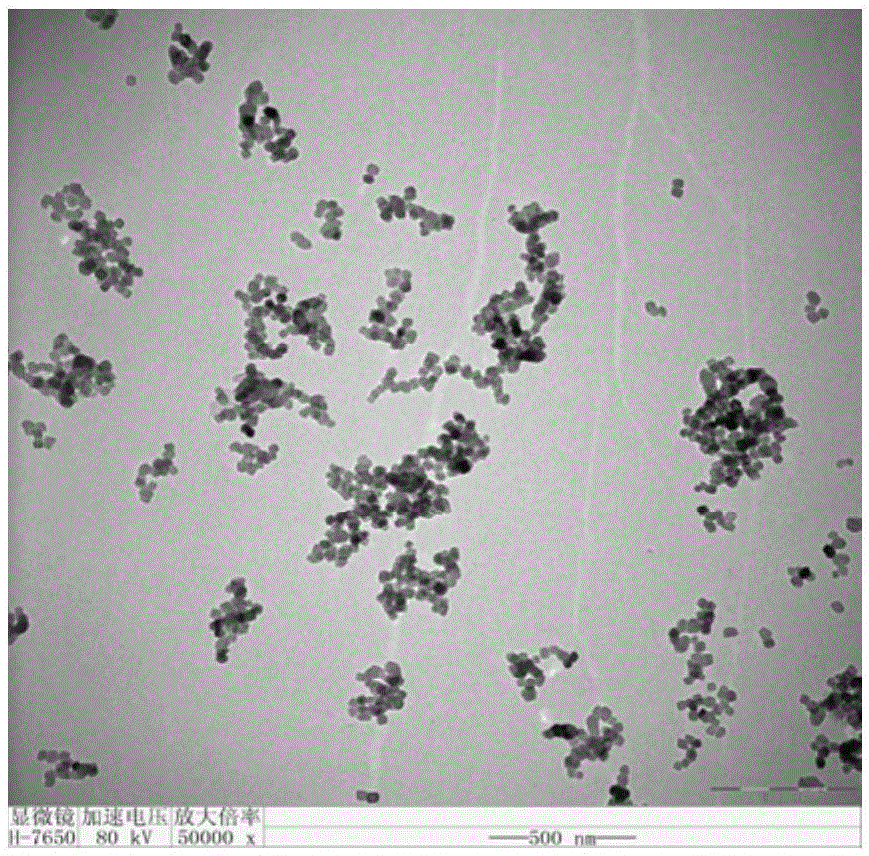

Embodiment 3

[0041] Put 32.21g of quicklime into 280g of water at 80°C, and digest it in a dispersion plate at a speed of 1000rpm for 2h; pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, and then add water to make a suspension with a mass fraction of 8wt%. , aged for 24 hours, and set aside;

[0042] the calcium hydroxide suspension in the step is dispersed in a dispersing disk with a rotating speed of 1000rpm in a linear cut, and 0.64g of 30% sulfuric acid solution is added to control the carbonization temperature to be 11°C, and a certain flow rate ( 60 / 120m 3 .h -1 .m -3 Suspension) CO 2 and N 2 The mixed gas is carbonized; after starting the carbonization reaction for 5min, add 1.07g30% PEG-600 and 16.11g10% silica sol solution (its SiO 2 The average particle size is 5-10nm, the pH is 9.0-10.5), and finally carbonized to pH = 6.7 to obtain the nanocomposite particle slurry;

[0043] Heat the slurry water bath in step to 80°C, and pass a small a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com