Full-automatic multi-level linkage binding machine and control method thereof

A fully automatic, binding machine technology, applied in binding and other directions, can solve problems such as low work efficiency, incoherent process connection, shortening binding time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

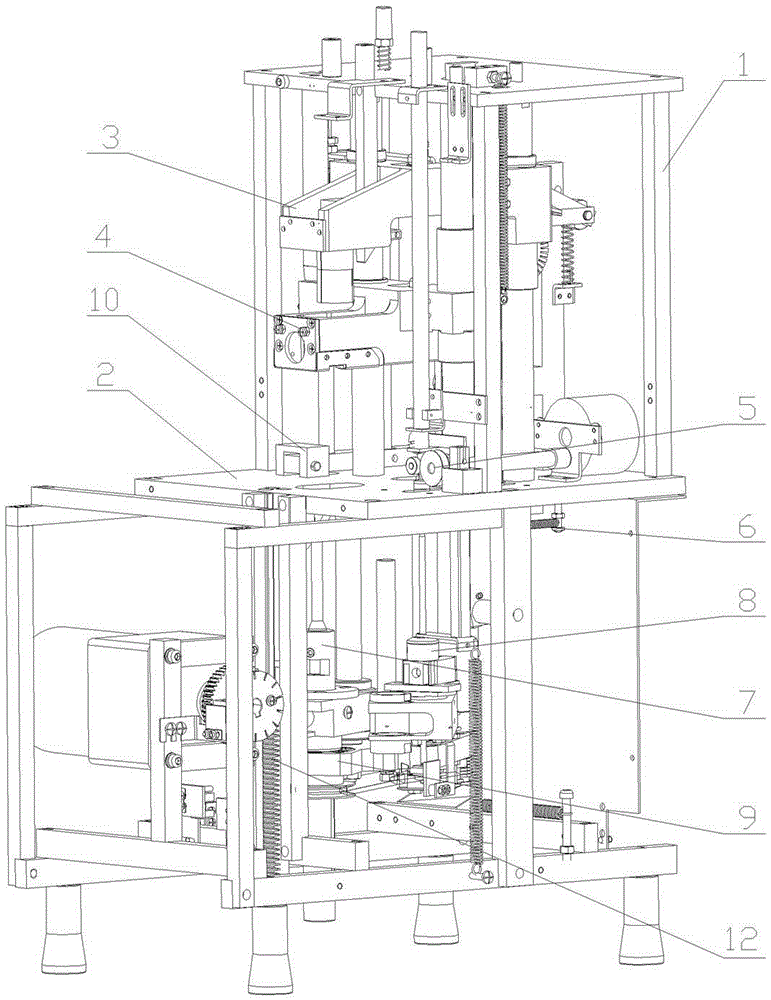

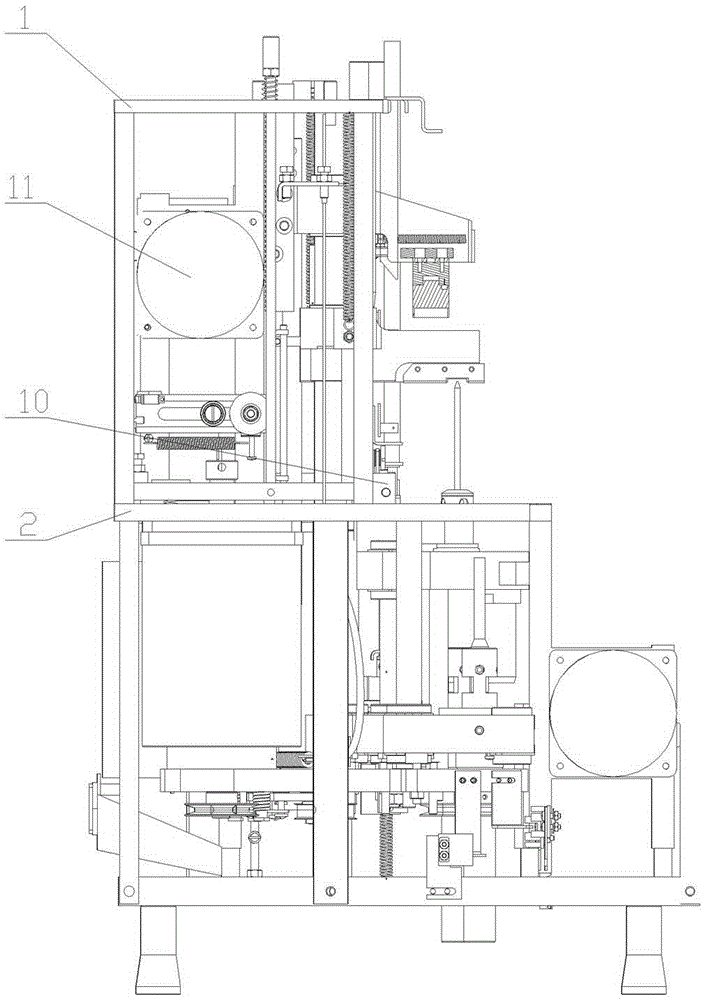

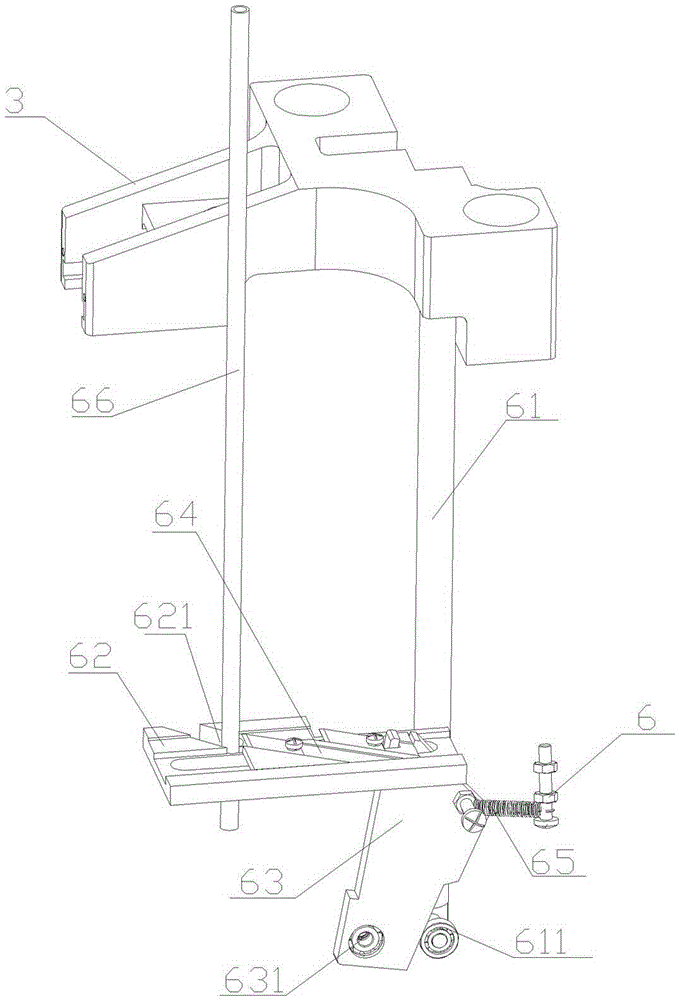

[0033] A multi-stage linkage automatic binding machine, the structure includes a frame 1, a workbench 2 located in the middle of the frame 1, an upper pressing mechanism 3 arranged above the workbench 2, and a matching pressing mechanism with a lifting transmission mechanism. Tightening driving mechanism 11, lower pressing mechanism 4, feeding mechanism 5, linkage type cutting mechanism 6 arranged under the workbench, drill mechanism 7, lower riveting mechanism 8 and linkage station conversion of the drill and lower riveting mechanism 9 and the co-position lifting and feeding mechanism 12, a control circuit with management software provided as a set, the upper pressing mechanism 3 is provided with a linkage telescopic shifting conductive rubber component, the key is:

[0034] The lower pressing mechanism 4 is equipped with a linkage type lower pressing brake and release mechanism 10 and a linkage telescopic displacement type upper riveting mechanism;

[0035] The station conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com