A corner aluminum profile extrusion die

A technology for extrusion dies and aluminum profiles, applied in metal extrusion dies and other directions, it can solve the problems of low average output and life, and achieve the effect of high die structural strength, consistent wall thickness, and improved die life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

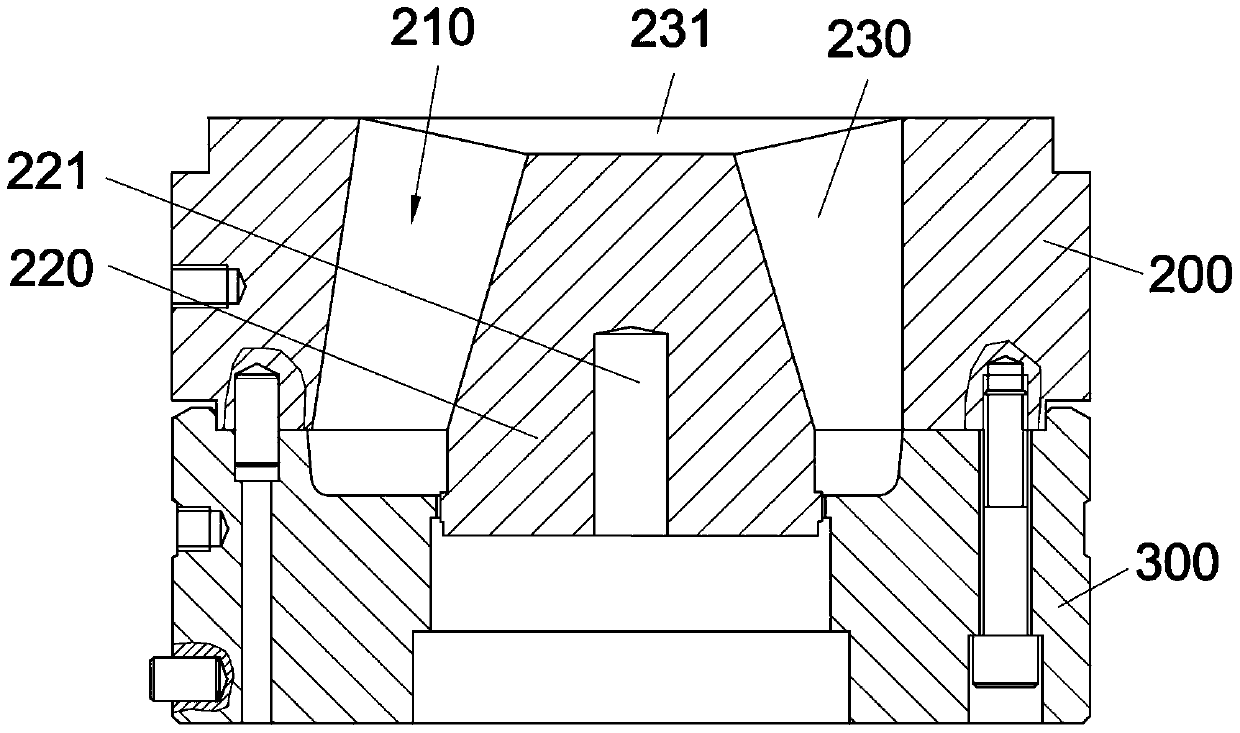

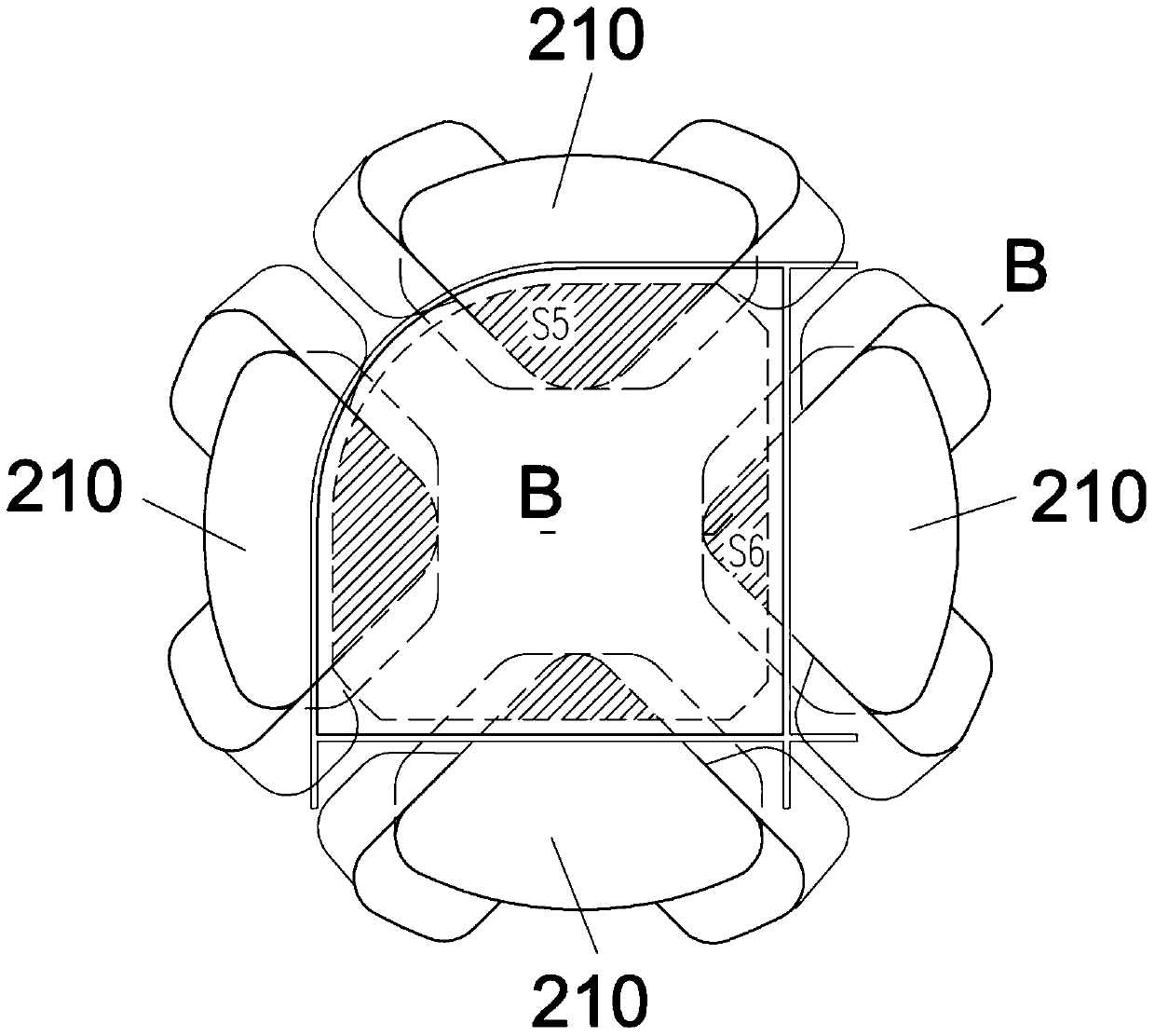

[0027] refer to Figure 1-6 , the embodiment of the present invention provides a corner aluminum profile extrusion die, including an upper die 200 and a lower die 300, the upper die 200 includes a core 220, and the lower die 300 includes The combined welding chamber 310, the upper mold 200 and the lower mold 300 are closed, and the mold core 220 of the upper mold 200 and the welding chamber 310 of the lower mold 300 form a working belt for forming the corner aluminum profile 100; the mold core The upper die 200 around 220 is provided with four diversion holes 210 corresponding to the four sides of the corner aluminum profile 100, and the diversion bridge 230 is between the diversion holes 210 and the diversion holes 210, and the diversion holes 210 adopt a parallel oblique entry type The structure, specifically, the inclination angle of the split hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com