Aluminum sheet encapsulating protective jacket and production process thereof

A technology of protective cover and encapsulation, applied in travel goods, applications, clothing, etc., can solve the problems of reducing the sensitivity of external keys and mobile phone keys, affecting GPS positioning signals, and falling off of soft rubber and frame, so as to avoid the damage of protective cover parts and The mobile phone falls off, ensuring tightness and good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

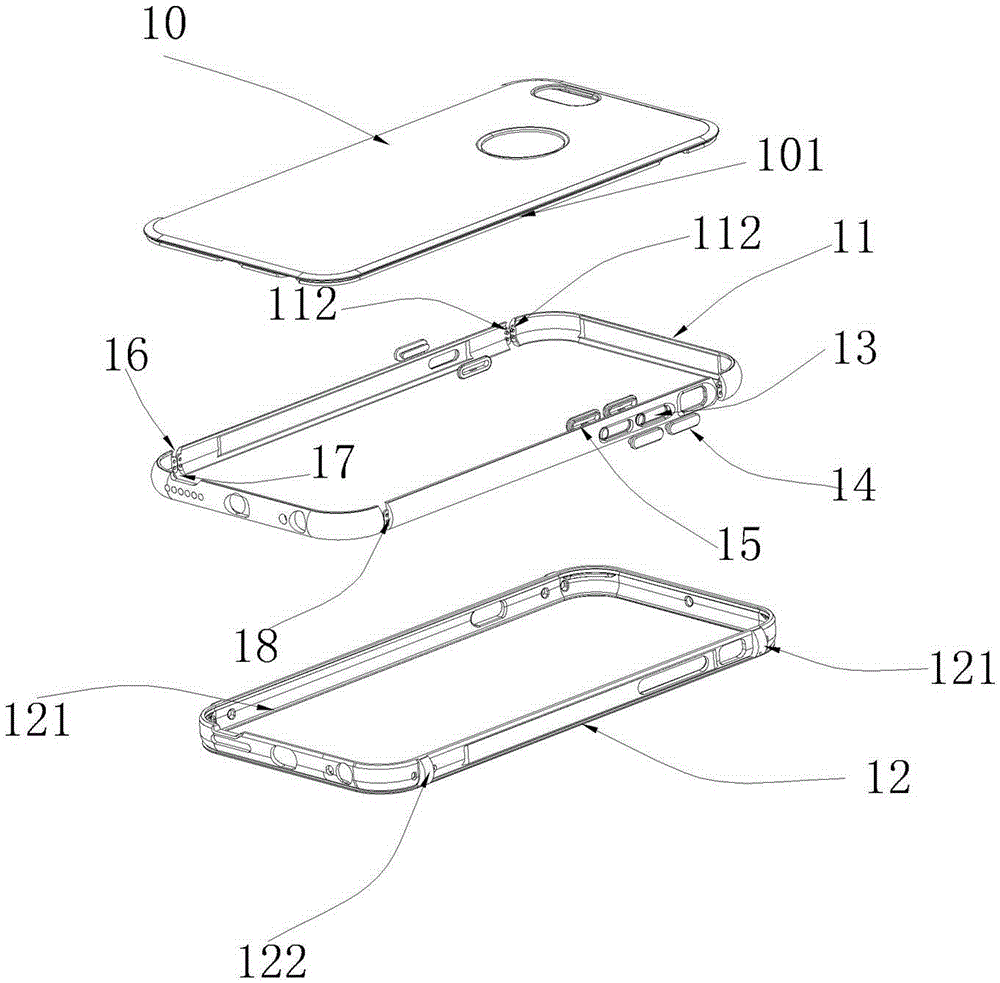

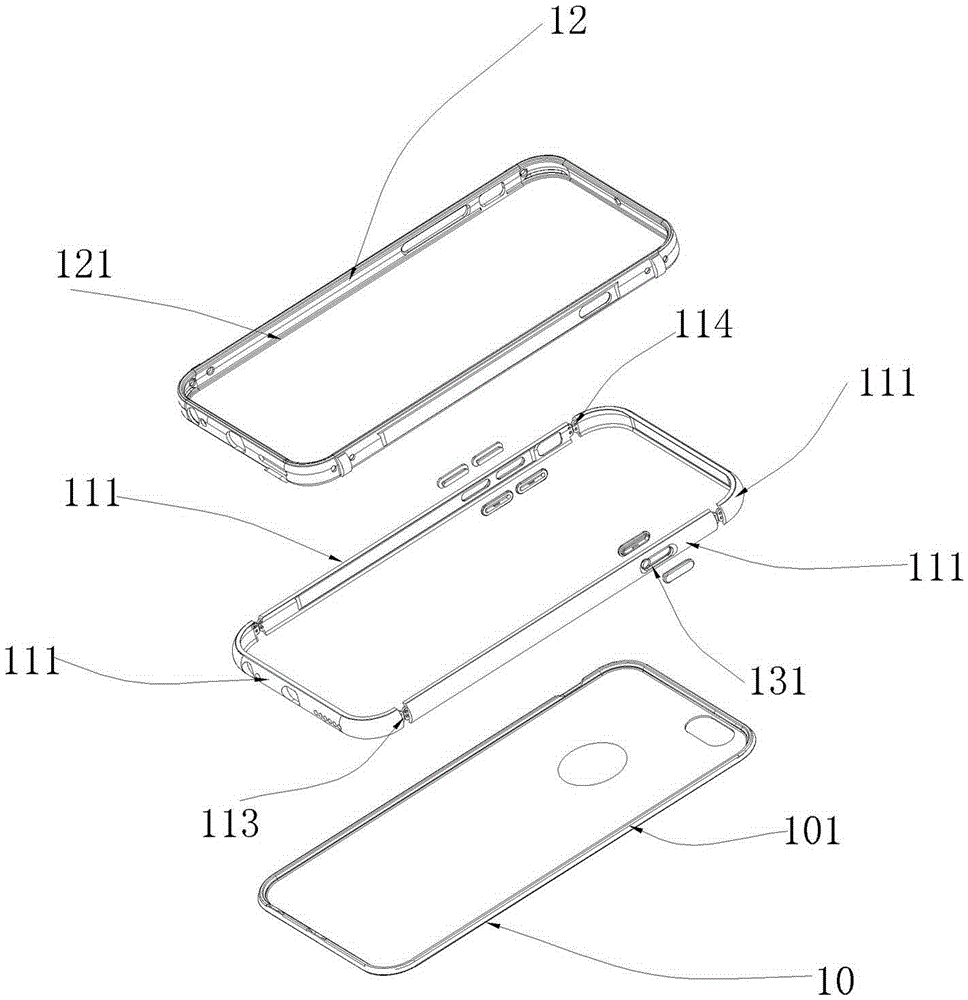

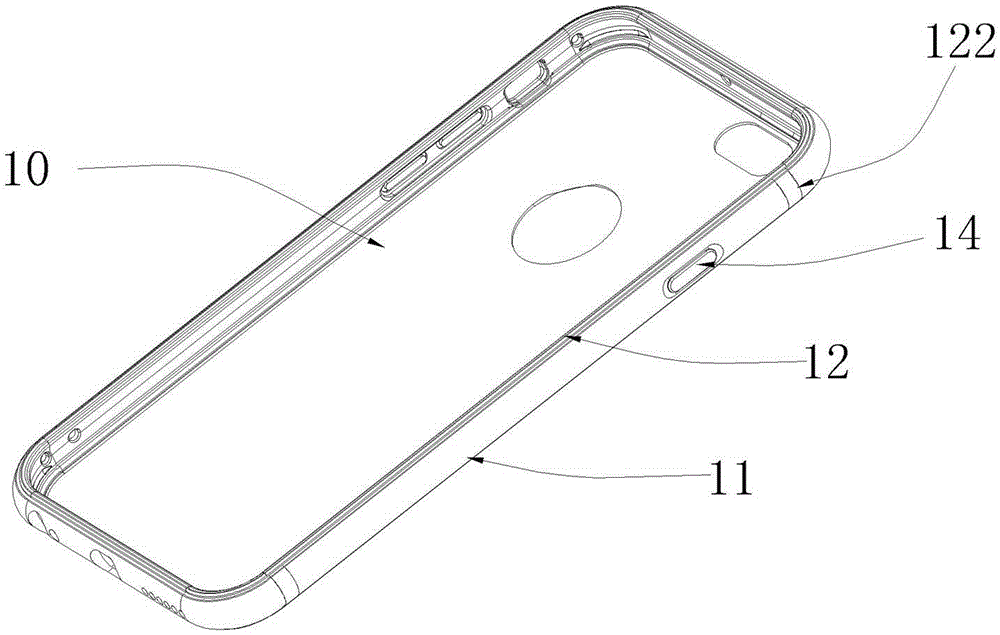

[0052] see Figure 1-3 , the aluminum sheet rubber-coated protective cover provided by the present invention includes a bottom plate 10 matching the shape and size of the bottom surface of the mobile phone and an outer aluminum frame 11 matching the shape and size of the outer frame of the mobile phone, and the inner wall of the outer aluminum frame 11 is formed by injecting adhesive The inner soft rubber frame 12 wrapping the inner wall of the outer aluminum frame; the bottom end of the bottom plate 10 extends downward near the edge with a snap ring 101, and the inner soft rubber frame 12 is recessed inward to form a ring that matches the shape and size of the snap ring 101 Card slot 121, after the snap ring 101 is snapped into the card slot 121, the bottom plate 10 is fixedly connected to the inner soft rubber f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com