Shell-and-tube apparatus for heat recovery from hot process stream

一种壳管式、工艺流的技术,应用在利用热载体的蒸汽发生方法、蒸汽分离装置、照明和加热设备等方向,能够解决没有提供完全令人满意解决方案等问题,达到相关风险减小、死点减小、降低总成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

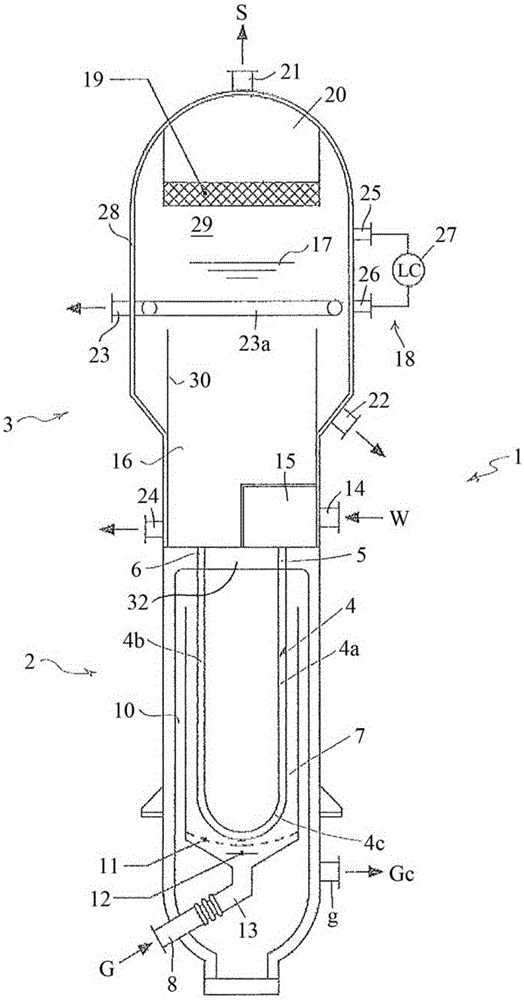

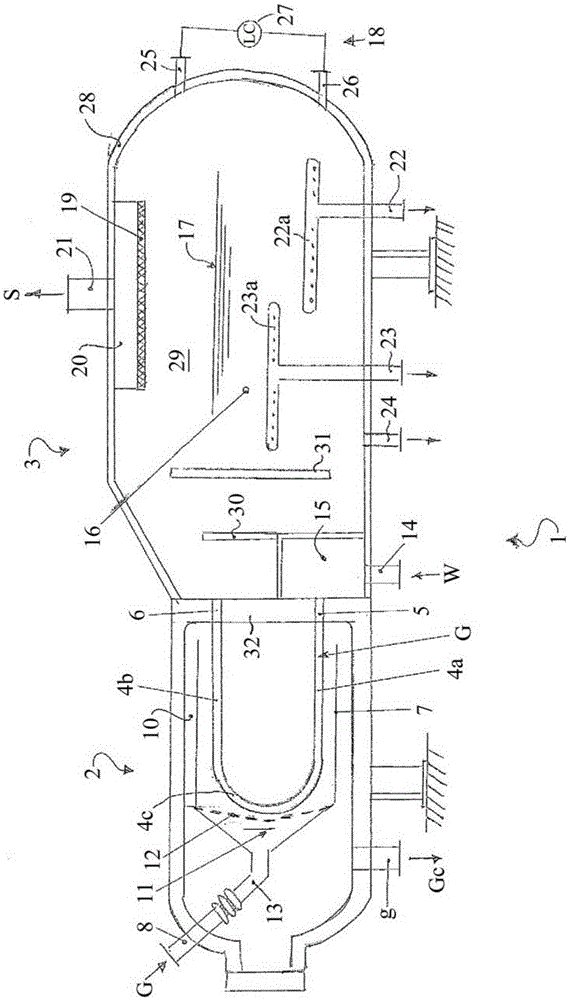

[0030] figure 1 A vertical shell and tube waste heat boiler 1 according to a preferred embodiment of the invention is shown.

[0031] Boiler 1 is designed to recover heat from hot gas G by heating and evaporating feed water W to generate steam S at a suitable pressure.

[0032] Said boiler 1 basically comprises a lower exchange section 2 embodied as a shell-and-tube heat exchanger and an upper separation section 3 receiving a mixed steam-water effluent from the tubes and designed to separate the steam from the non-evaporated water separate.

[0033] In more detail, the lower part 2 comprises a bundle of tubes 4 with respective tube inlet ends 5 and tube outlet ends 6 and a thermal chamber 7 surrounding said tubes 4 . This lower part 2 operates substantially as a shell and tube heat exchanger, where the tubes are fed with water W and hot gas G passes through the shell side (ie the thermal chamber 7 ).

[0034] The bundle of tubes is shown schematically. Each tube 4 is a U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com