Method and apparatus for feeding in and handling waste material

一种废弃物、物料的技术,应用在输送散装物料、应用、家里用具等方向,能够解决中间容器空间需求大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

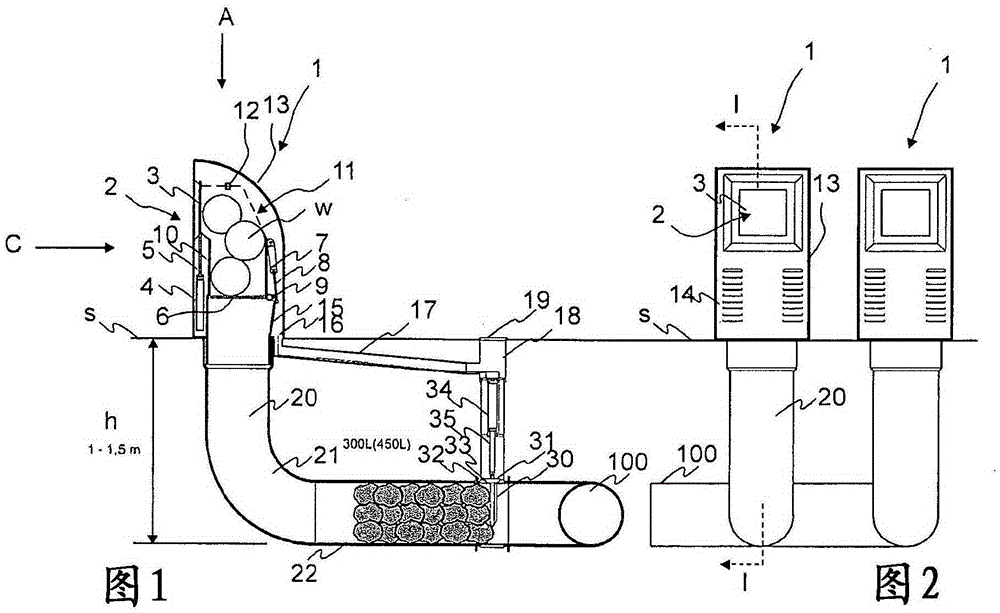

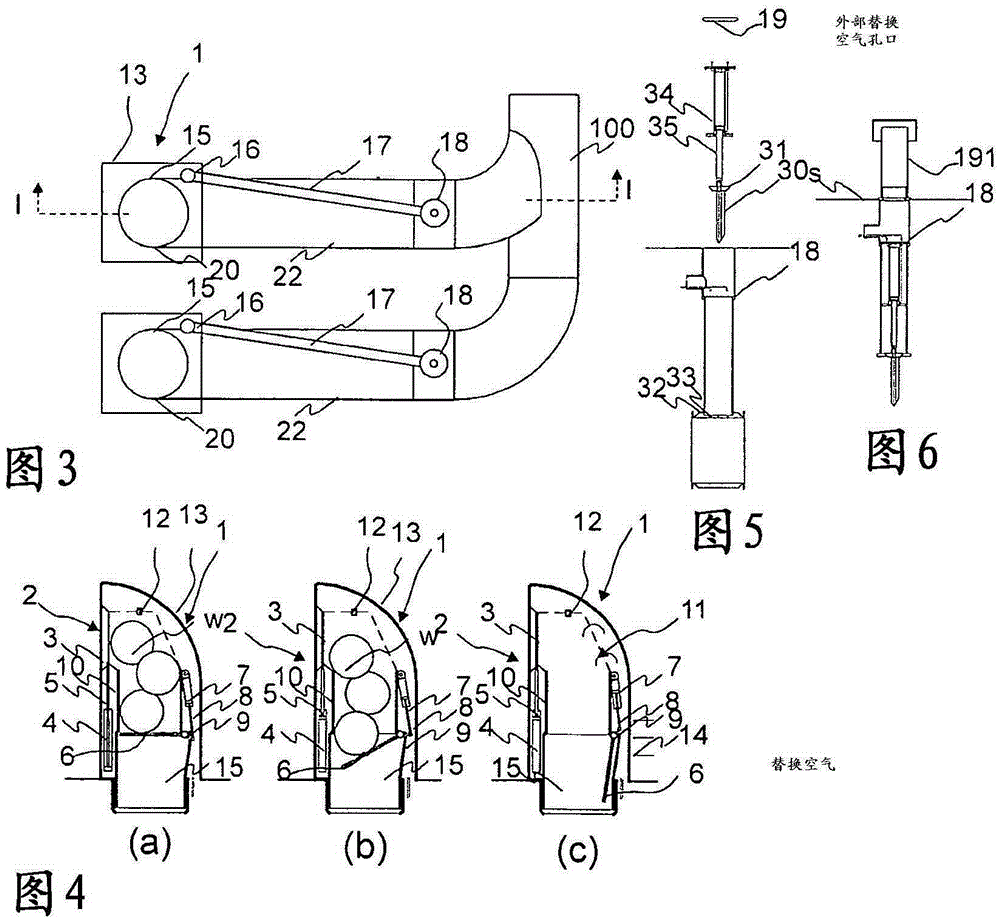

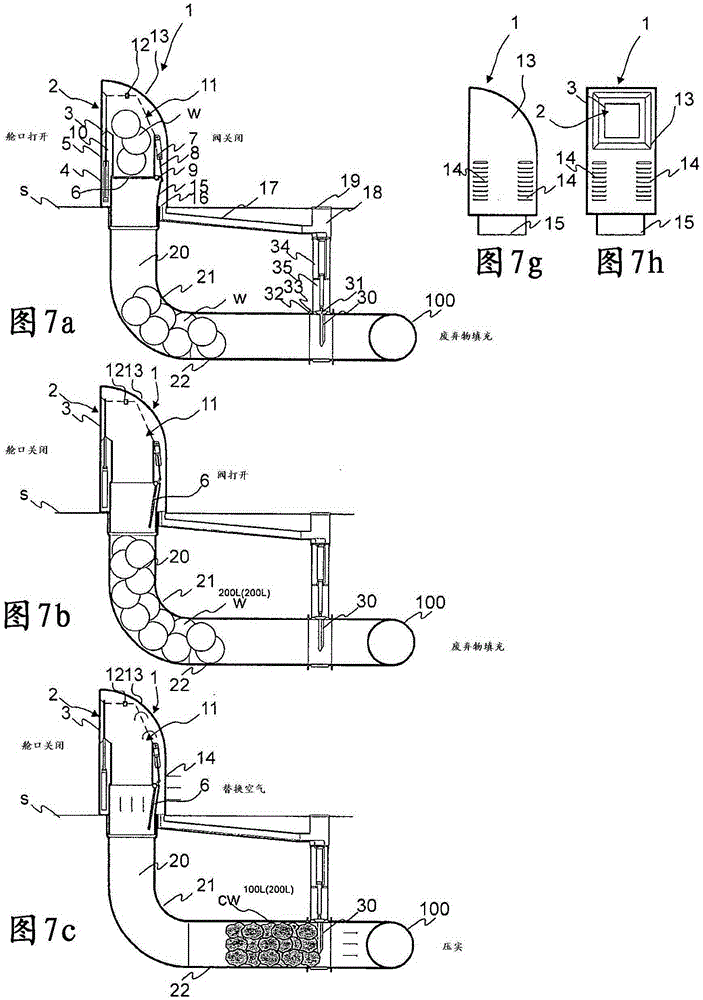

[0040] figure 1 , 2 and 3 provide a simplified view of the device according to the invention. The plant comprises an input point 1 comprising an input orifice 2 for feeding material w, such as waste material or recyclable material, into a feed container 10 of the input point, and via an intermediate container 20 , 21 , 22 are fed forward into the material transfer conduit 100 . In the embodiment of the figure, an openable and closable hatch 3 or corresponding means is connected to the input orifice 2, the hatch, when closed, covers the input orifice 2 and, when open, enables the material w Feed into the feed container 10. In the embodiment of the figure, an actuator 4, 5 (for example a cylinder-piston combination) is arranged to drive the hatch 3 of the input orifice, by means of which the hatch 3 is arranged to be able to Movement between at least two positions, a first position in which the hatch covers the input opening 2 and a second position in which the input opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com