Automobile pneumatic tire

A technology for pneumatic tires and passenger cars, which is applied to the reinforcement layer of pneumatic tires, tire parts, and the absence of a separate inflatable cushion. Effects of resistance, improvement of fuel consumption, and reduction of rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

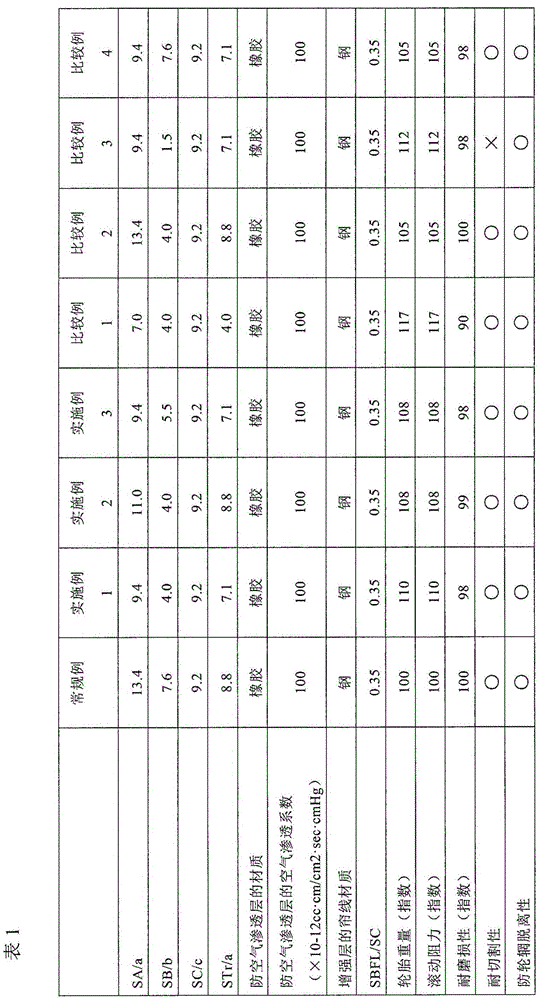

[0064] The tire size is 195 / 65R15, and a ply is erected between a pair of bead parts, a bead core is buried in each bead part, a bead filler is arranged on the outer peripheral side of each bead core, and a bead filler is placed on the outer peripheral side of the ply In a pneumatic tire in which two reinforcement layers are arranged, a tread rubber layer is laminated on the outer peripheral side of the reinforcement layer, and an air permeation prevention layer is provided on the inner surface of the tire, as shown in Table 1 and Table 2, the first boundary and the second The cross-sectional areas SA, SB, SC (mm 2 ) and the ratios SA / a, SB / b, SC / c obtained from the edge lengths a, b, c (mm), the ratio STr / a related to the cross-sectional area STr in the first region of the tread rubber layer, and the anti-air The material of the permeable layer, the air permeability coefficient of the anti-air permeation layer, the cord material of the reinforcing layer, and the ratio S relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com