Superfine fiber dye with high light fastness and preparation method thereof

A technology of ultra-fine fiber and dyestuff, applied in the field of dyestuff, can solve the problems of low quality rate and inability to meet requirements, and achieve the effects of increasing production cost, improving comprehensive performance and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

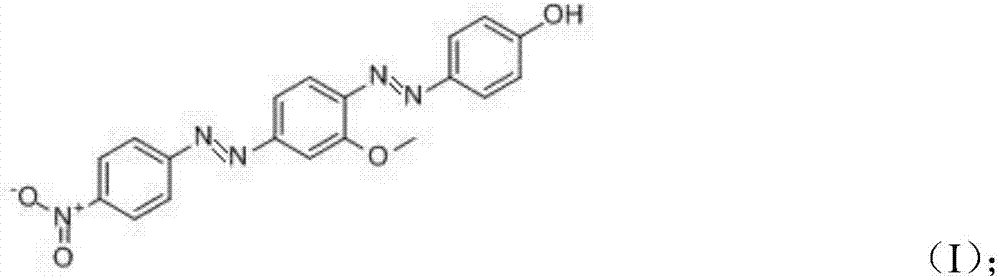

[0023] Superfine fiber dye with high light fastness, mix the following components separately, component A: 30%, component A is disperse orange 29#, component B: 10%, component B is disperse red 167#, component C: 14%, component C is disperse blue 60#, component D: 38%, component D is disperse blue 56#. The dispersant has a lignin content of 8%, and forms a black color dye composition. Described component A, its structural formula (I) is as follows:

[0024]

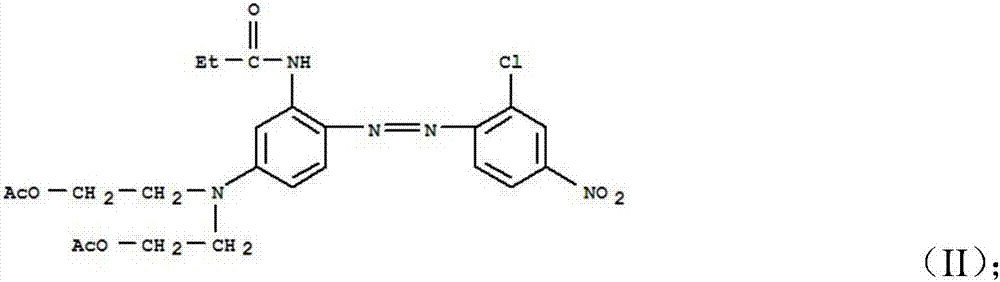

[0025] Described component B, its structural formula (II) is as follows:

[0026]

[0027] Described component C, its structural formula (III) is as follows:

[0028]

[0029] Described component D, its structural formula (IV) is as follows:

[0030]

[0031] According to the above-mentioned component distribution ratio, each component is weighed for proportioning, crushed and granulated. In this step, glass balls are used as the grinding medium for grinding, and the glass balls are ground and filtered; the...

Embodiment 2

[0033] Superfine fiber high light fastness dye, mix the following components respectively, component A: 34%, component A is disperse orange 29#, component B: 10%, component B is disperse red 167#, component C: 14%, component C is disperse blue 60#, component D: 38%, component D is disperse blue 56#. The dispersant has a lignin content of 4% to form a black color dye composition, the molecular formula of which is shown in Example 1. According to the above component distribution ratio, each component is weighed for proportioning, crushed and granulated. In this step, glass balls are used as the grinding medium for grinding, and the glass balls are ground and filtered; the diameter of the glass balls is 1-2 μm. Spray drying or drying in an oven, the inlet temperature of spray drying is 110°C, and the outlet temperature is 60°C. Then add dispersant and stir in the blending equipment for 1 hour until the diffusion level reaches level 4. Dry blending is carried out at a temperature...

Embodiment 3

[0035] Superfine fiber dye with high light fastness, mix the following ingredients separately, component A: 30%, component A is disperse orange 29#, component B: 15%, component B is disperse red 167#, component C: 14%, component C is disperse blue 60#, component D: 38%, component D is disperse blue 56#. The dispersant MF content is 5%, and the black color dye composition is formed, and the molecular formula is as shown in Example 1. According to the above component distribution ratio, each component is weighed for proportioning, crushed and granulated. In this step, glass balls are used as the grinding medium for grinding, and the glass balls are ground and filtered; the diameter of the glass balls is 2 μm. Spray drying or drying in an oven, the inlet temperature of spray drying is 120°C, and the outlet temperature is 60-70°C. Then add the dispersant and stir in the blending equipment for 1-2 hours until the diffusion level reaches 3-4 level. Dry blending is carried out under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com