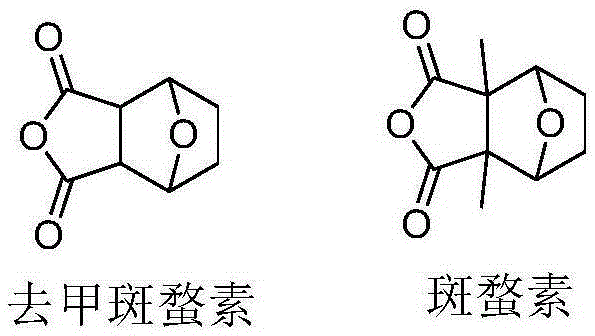

Acid-sensitive camptothecin-site 20 norcantharidate derivative and antineoplastic application thereof

A technology for methylcantharidinate and camptothecin, which is applied in the field of new drug design and synthesis, can solve the problems of long-term use, large toxic and side effects, etc., and achieves the effects of easy hydrolysis, easy availability of raw materials, and easy operation and implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 , Preparation of 5-ene-norcantharidin 2:

[0034] Take out a certain amount of maleic anhydride 1 from the reagent bottle, place it in a dry grinder and grind it finely, then weigh 12.021g of the finely grinded maleic anhydride with an electronic balance, put it in a dry three-necked flask, stopper Put on the stopper, add diethyl ether and stir, and when the amount of diethyl ether is 90mL, the maleic anhydride is completely dissolved. After the maleic anhydride was completely dissolved, 13 mL of furan was slowly added through the dropping funnel for 13 minutes. The temperature was controlled to start the reaction at 38°C. After reacting for 1 hour, white solids appeared in the solution, and the longer the time, the more white solids there were. After reacting for 24 hours, it was suction-filtered to obtain Compound 2 as a white solid, namely 5,6-didehydronorcantharidin. The dry weight is 17.459g, and the yield is 85.75%. Melting point: 122~123℃, ratio sh...

Embodiment 2

[0036] Example 2 , the preparation of 5-ene-norcantharidin monoacid benzyl ester 3:

[0037] Weigh 5 g of raw material 2 and dissolve it in 40 ml of dichloromethane to form a suspension. Then, 4.7ml of benzyl alcohol and 366mg of DMAP were added dropwise to the suspension. Stirred at room temperature for 3 days, the solvent was removed by rotary evaporation to obtain the crude product of 5,6-didehydronorcantharidin monomethyl ester 2. Dissolve the obtained crude product in 25ml of dichloromethane, wash once with 7ml of 1N hydrochloric acid, leave the organic phase, then wash once with 10ml saturated brine, leave the organic phase, add an appropriate amount of anhydrous MgSO 4 Dry for 15-30 minutes, filter with suction, rinse the filter cake 2-3 times with dichloromethane, leave the filtrate, and the filtrate is rotary evaporated to obtain a white solid of 5-ene-norcantharidin monoacid benzyl ester 3 (4.08g ), the yield is 50%. 1 HNMR (DMSO-d 6): δ12.43(s,1H),7.30-7.35(m,5...

Embodiment 3

[0038] Example 3. Preparation of camptothecin (2-benzyloxycarbonyl-5-ene) norcantharidinate 4

[0039]

[0040] Add camptothecin (60mg, 0.17mmol) and 10ml methylene chloride in the reaction flask, then add 5-ene-norcantharidin monoacid benzyl ester (3,93.2mg, 0.34mmol, 2equ.), EDCI ( 161.3 mg, 0.84 mmol) and DMAP (13.4 mg, 0.11 mmol). The reaction solution was heated to reflux for 24 hours. Add dichloromethane (30ml) to dilute the reaction solution, and wash with water, saturated sodium carbonate solution and saturated brine successively. Anhydrous MgSO for organic phase 4 dry. After the solvent was spin-dried, the residue was purified by column chromatography to obtain a coupling product (compound 4, 73.5 mg) as a yellow solid, with a yield of 71.6%. R f =0.44 (DCM / MeOH=95 / 5). 1 HNMR (CDCl 3 ): δ8.39(s,1H),8.20(d,J=8Hz,1H),7.94(d,J=8Hz,1H),7.84(d,J=8Hz,1H),7.81(s,1H) ,7.67(t,J=8Hz,1H),7.38(m,5H),7.18(s,1H),6.99(d,J=4Hz,1H),5.71(d,J=8Hz,1H),5.42( d,J=8Hz,1H),5.27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com