A kind of high mn and high nb crack-resistant nickel-based welding wire and its welding method

An anti-crack and defect technology, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of high Mn and high Nb anti-crack and defects that are prone to cracks, and achieve good wire feeding performance, good forming, and no scum Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

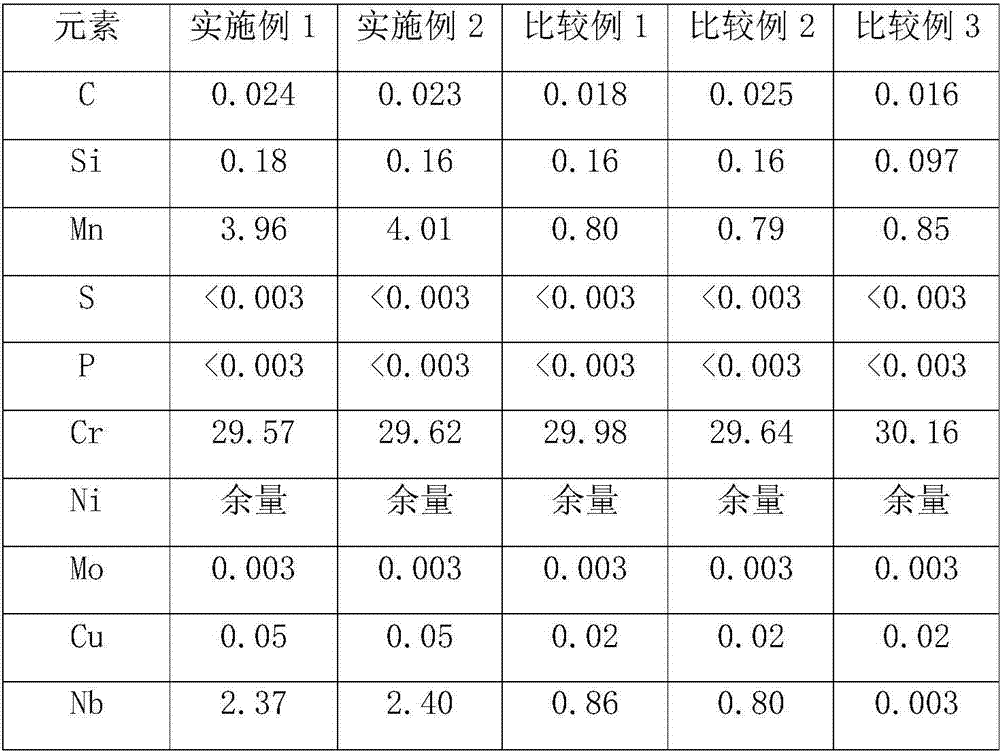

[0016] Example 1, the master alloy steel ingot is forged and rolled, then subjected to multi-pass cold drawing and online annealing, and after cleaning, a welding wire is finally formed, and finally the chemical composition of the welding wire is C: 0.024%, Si: 0.18%, Mn: 3.96%, S: <0.003%, P: <0.003%, Cr: 29.75%, Mo: 0.03%, Cu: <0.05%, Nb: 2.37%, Mn+Nb: 6.2-6.6%, Ti: 0.55 %, Al:0.18%, Fe:9.00%, Ca:<0.005%, Mg:<0.005%, O:<0.005%, N:0.29%, B:<0.001%, Zr:<0.005%, Ta:< 0.02%, Ni is the balance.

Embodiment 2

[0017] Example 2, the master alloy steel ingot is forged and rolled, then subjected to multi-pass cold drawing and online annealing, and after cleaning, a welding wire is finally formed, and the chemical composition of the welding wire is finally C: 0.02, 3%, Si: 0.16 %, Mn:4.01%, S:<0.003%, P:<0.003%, Cr:29.62%, Mo:0.03%, Cu:<0.05%, Nb:2.40%, Ti:0.50%, Al:0.19%, Fe:8.36%, Ca:<0.005%, Mg:<0.005%, O:<0.005%, N:0.28%, B:<0.001%, Zr:<0.005%, Ta:<0.02%, Ni is the balance .

[0018] In the present invention, the welding wire can be smelted in a vacuum induction furnace, or can be smelted in an electric furnace plus refining outside the furnace, as long as the final chemical composition of the welding wire can meet the requirements of the above content of the invention.

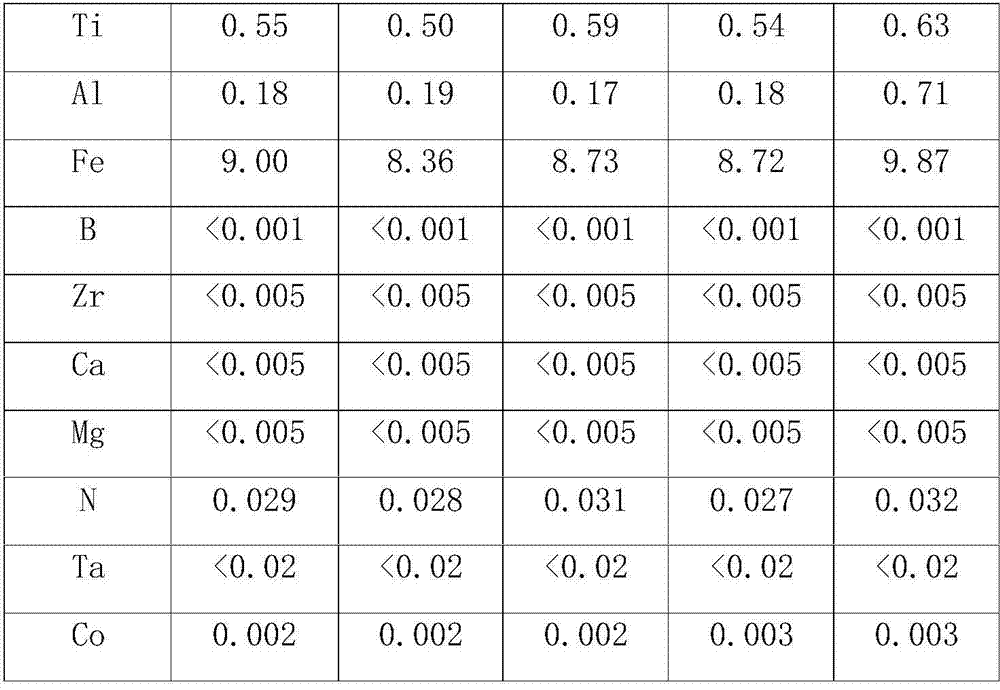

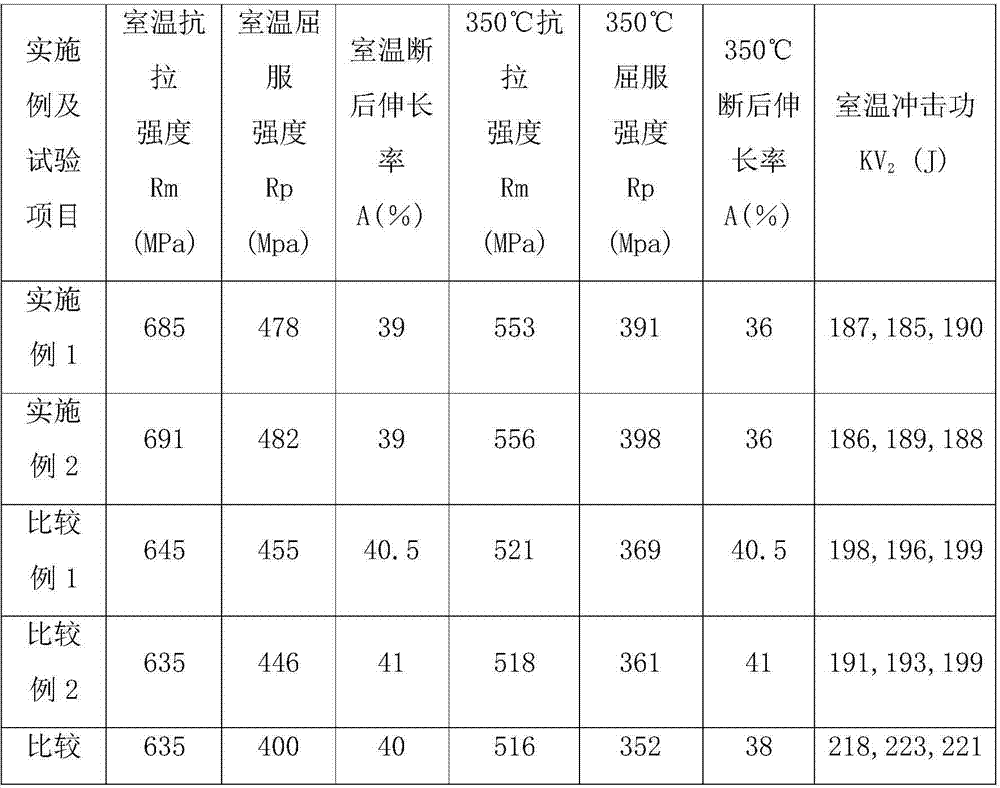

[0019] In order to verify the effects of the present invention, the following two examples are compared with three comparative examples.

[0020] Table 1 is the basic chemical composition (weight ratio %) of embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com